Page

Please Read Prior to Installation for Safety

Preface

Page

Table of Contents

Fault Code Information

Troubleshooting

Start Up

Digital Keypad Operation

All Brake Resistors & Brake Units Used in AC Motor Drives

Appendix C How to Select the Right AC Motor Drive

Appendix D CE

Introduction

Receiving and Inspection

Nameplate Information

Model Explanation

Drive Frames

Series Number Explanation

Appearances

Installation Steps

Storage

IntroductionVFD-S Series

This page intentionally left blank

Installation

Installation and Wiring

Ambient Conditions

150mm 6inch

Dimensions

85.0 88.0 74.0 13.0 132.25.21 148.05.83 4411.1

88 .0 3 .4

10 2 4

85 .0 3 .3 10 2 4 74 .0 2 .9

85 .0 3 .3 74 .0 2 .9

50 .0 1 .9

Frame S1 VFD007S21B

12 6 4

67 .8 2 .6 51 .0 2 .0

12 7 5

Frame S2 VFD007S11A

67 .8 2 .6

Frame S2 VFD007S11B

12 9 5

100.0 86.5 173.0 186.0 129.3 16.0

Wiring

Basic Wiring

Basic Wiring Diagrams

NFB

For Vfdxxxsxxe NPN sink mode

For Vfdxxxsxxe PNP source mode

External Wiring

FUSE/NFB

Main Terminals Connections

Mains power terminals R/L1, S/L2, T/L3 and L/L1, N/L2

Control circuit terminals U/T1, V/T2, W/T3

Terminals +2/B1, +1 for connecting DC reactor

Terminals +2/B1, B2 for connecting brake resistor

Grounding terminals

No ground loops

Terminal symbols and functions

Control Terminals

GND

AVI/ACI

Digital outputs MO1, MCM

General

Power terminal

Main Circuit Terminals

AC Input Line Motor Terminal

VFD002S21A/E, VFD004S21A/E, VFD007S21A/E

Power terminal

VFD015S21U/43D/43E/43U, VFD022S21U/23D/43D/43E/43U

VFD015S21D/E, VFD022S21D/E

This page intentionally left blank

Start Up

Preparations before Start-up

Operation Method

Trial Run

Start UpVFD-S Series

This page intentionally left blank

Explanation of LED Indicators

Digital Keypad Operation

Description of the Digital Keypad

Explanations of Display Messages

Digital Keypad OperationVFD-S Series

How to Operate the Digital Keypad

To shift data

This page intentionally left blank

Parameters

Group 0 User Parameters Explanation Settings Factory

Summary of Parameter Settings

Group 1 Basic Parameters Explanation Settings Factory

Group 2 Operation Method Parameters Explanation Settings

Explanation Settings Factory

Setting

Group 3 Output Function Parameters

Group 4 Input Function Parameters Explanation Settings

Forward/reverse N.O. motion

Group 6 Protection Parameters Explanation Settings

Explanation Settings Factory

Group 8 Special Parameters Explanation Settings Factory

Group 7 Motor Parameters Explanation Settings Factory

Group 9 Communication Parameters

Group a PID Parameters Explanation Settings Factory

Explanation Settings Factory

Parameter Settings for Applications

Wire

ParametersVFD-S Series

Running status External system or control wiring

ParametersVFD-S Series

Description of Parameter Settings

Would be displayed as

ParametersVFD-S Series

END

Bit Bit4

Group 1 Basic Parameters

Standard V/F Curve

Factory Setting d10.0

Command

Acceleration/deceleration Characteristics

Group 2 Operation Method Parameters

01Source of Operation Command

10kHz

115V/230V/460V Series

05Loss of ACI Signal 4-20mA

Analog Frequency Meter Analog Current Meter

OFF

Setting Function Description

TRG

Setting Function Description

Group 4 Input Function Parameters

Example

This example shows a potentiometer range of 0 to 5 Volts

Potentiometer Scale

Max Output Pr.1-00 Freq 60Hz

Parameters & Functions table

Explanations D0 Parameter Disable

REV/STOP

D6 External Reset

D4, d5 External Faults

D7, d8, d9 Multi-Step Speed Command

D10 Jog Operation Control

D11 Acceleration/Deceleration Speed Inhibit

D12 First or Second Acceleration/Deceleration Time Selection

D13, d14 External Base Block

D15, d16 Increase/Decrease Master Frequency

D17, d18 PLC Function Control

D19 Counter Trigger

D20 Counter Reset

D22 PID function disable

D28 Press UP/DOWN key to switch forward/reverse N.C. motion

D21 Select ACI / Deselect AVI

09Line Start Lockout

ParametersVFD-S Series

Example 2 Pr.5-07 = d2 Continuously executes program cycles

Example 3 Pr -07 = d3 Execute one cycle step by step

Weights =Forward Bit =Reverse

Example 5 Pr -07 = d1 Execute one cycle of the PLC program

Weights Bit Direction

Group 6 Protection Parameters

Over-voltage Stall Prevention

Factory Setting d150

Present Fault Record

ParametersVFD-S Series

Group 7 Motor Parameters

Output Frequency

Group 8 Special Parameters

Factory Setting d2.0

Maximum Allowable Power Power Loss Time

ParametersVFD-S Series

00Communication Address Settings D1 to d254

+EV

Ascii mode

RTU mode

Stop

LRC CHK

6FH

LRC CHK END1 END0

Starting data address ‘0’ ‘4’ ‘1’

Content Address Functions

Read only

PID error Pld

Error Meaning Message

Exception Meaning Code

Communication program of PC

Group a PID Control

Unit 2 msec

Sleep Function

13 = 56-0X 100100 X 10 =

Fault Code Information

Common Problems and Solutions

Fault Fault Descriptions Corrective Actions Name

Over current

GFF hardware error

OC hardware error

Overheating

Low voltage

Fault Descriptions Corrective Actions Name

External Fault

OH error OV error LV error

Current detection error DC BUS detection error

Reset

Troubleshooting

Over Current OC

Ground Fault

Over Voltage OV

Low Voltage Lv

Over Heat OH

Overload

Phase Loss PHL

Keypad Display is Abnormal

Motor cannot Run

Motor Speed cannot be Changed

Motor Stalls during Acceleration

Motor does not Run as Expected

Electromagnetic/Induction Noise

Environmental Condition

Serial reactor Phase lead capacitor

Affecting Other Machines

Daily Inspection

Maintenance and Inspections

Periodic Inspection

Voltage Maintenance Check Items Methods and Criterion

Keypad Maintenance Check Items Methods and Criterion

Check Items Methods and Criterion Period

Change of copper plate

Year

Change fan To overheating

This page intentionally left blank

Appendix a Specifications

Voltage Class 115V Class 230V Class 460V Class

Appendix a SpecificationsVFD-S Series

Appendix B Accessories

All Brake Resistors & Brake Units Used in AC Motor Drives

Dimensions and Weights for Brake resistors

Installation

EMI Filters

Saddle on both ends Saddle on one end

Length of motor cable

Order P/N RF007S21AA/ RF007S43AA

Order P/N RF022S21BA

Order P/N 12DKT1W3S

Order P/N 08TDT1W4S

Order P/N 22DRT1W3S

Order P/N 35DRT1W3C

AC Reactor AC Input Reactor Recommended Value

~5% impedance

Applications for AC Reactor

AC Output Reactor Recommended Value

Impedance

May be damaged when over current occurs during operation

M1 reactor

Small-capacity

DC Choke Recommended Values

MTE CAT. no

Zero Phase Reactor RF220X00A

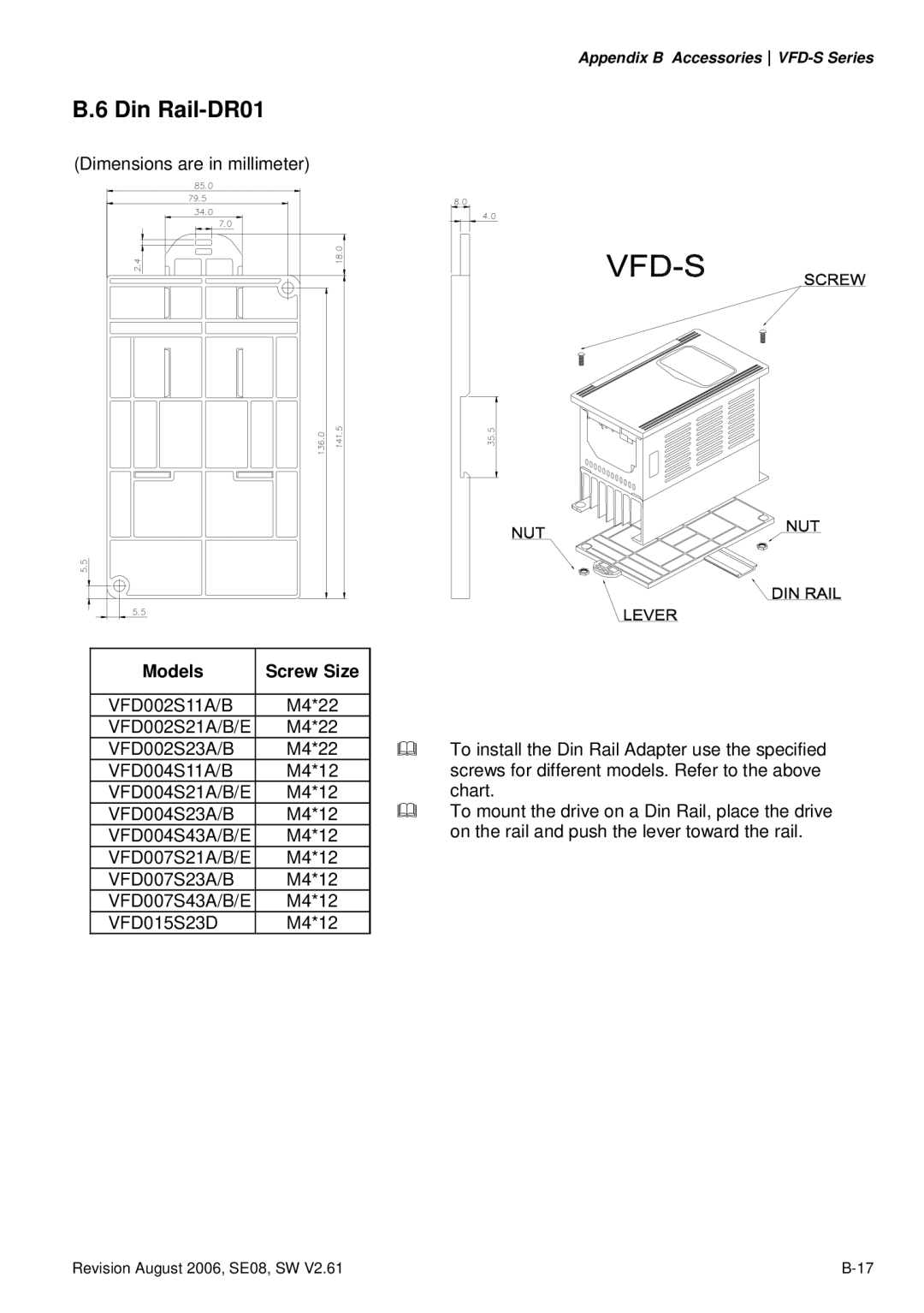

Din Rail-DR01

Models Screw Size

Remote Controller RC-01

Conduit Bracket BK-S

Non-fuse Circuit Breaker Chart

Fuse Specification Chart

Appendix C How to Select the Right AC Motor Drive

Related Specification

When one AC motor drive operates more than one motor

When one AC motor drive operates one motor

Capacity Formulas

⋅ IM ≤ the rated current of AC motor drive a

Parameter Settings Note

General Precautions

Selection Note

How to Choose a Suitable Motor

Standard motor

Special motors

Pole-changing Dahlander motor

Power Transmission Mechanism

Motor torque

AC motor drive

Appendix D CE

Delta ELECTRONICS, INC

Delta ELECTRONICS, INC