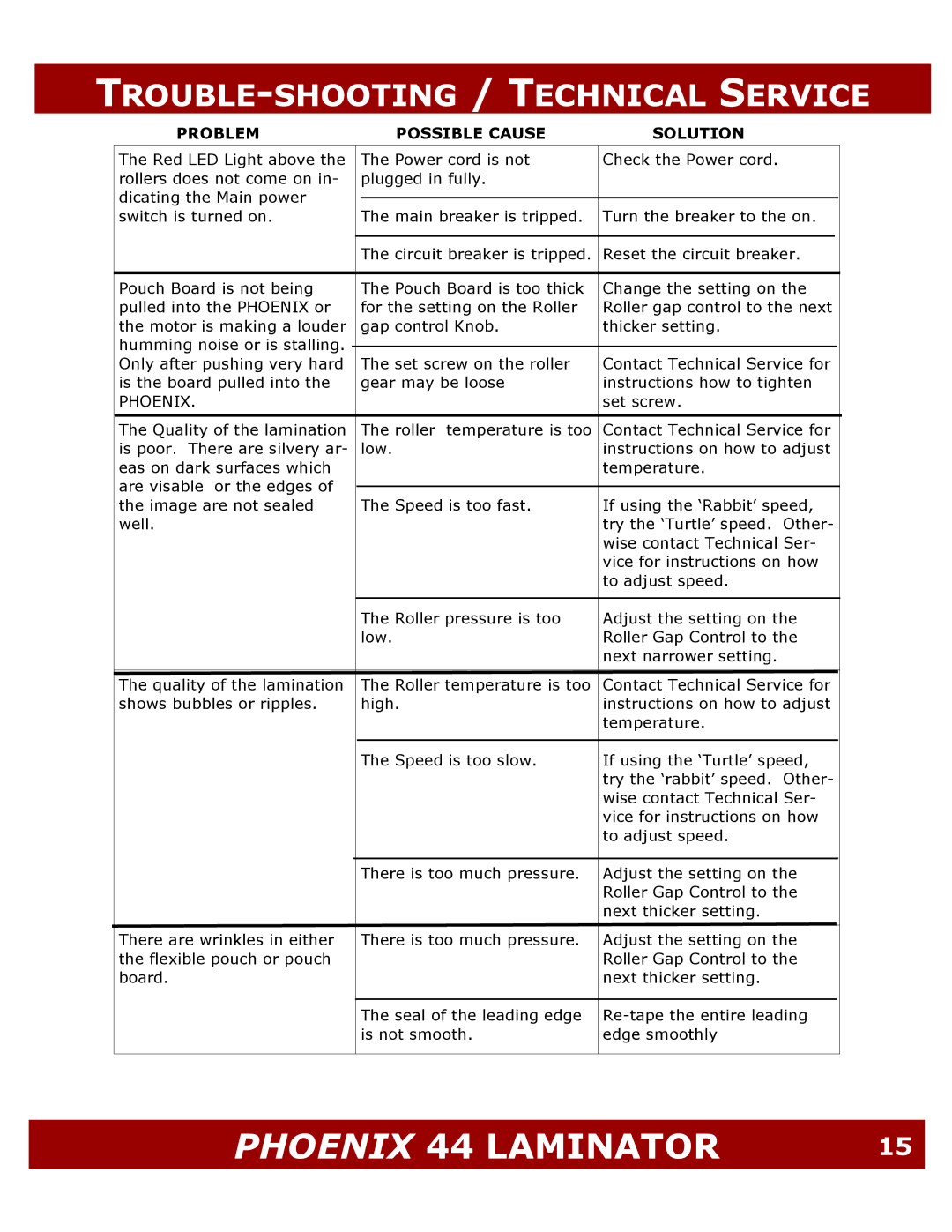

TROUBLE-SHOOTING / TECHNICAL SERVICE

PROBLEM |

| POSSIBLE CAUSE | SOLUTION | |||||

|

|

|

|

|

|

|

|

|

The Red LED Light above the | The Power cord is not | Check the Power cord. | ||||||

rollers does not come on in- | plugged in fully. |

|

|

| ||||

dicating the Main power |

|

|

|

|

| |||

|

|

|

|

| ||||

switch is turned on. | The main breaker is tripped. | Turn the breaker to the on. | ||||||

|

|

|

|

|

|

|

| |

|

|

|

| The circuit breaker is tripped. | Reset the circuit breaker. | |||

|

|

|

|

| ||||

Pouch Board is not being | The Pouch Board is too thick | Change the setting on the | ||||||

pulled into the PHOENIX or | for the setting on the Roller | Roller gap control to the next | ||||||

the motor is making a louder | gap control Knob. | thicker setting. | ||||||

humming noise or is stalling. |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| ||

Only after pushing very hard | The set screw on the roller | Contact Technical Service for | ||||||

is the board pulled into the | gear may be loose | instructions how to tighten | ||||||

PHOENIX. |

|

| set screw. | |||||

|

|

|

|

|

|

|

|

|

The Quality of the lamination | The roller temperature is too | Contact Technical Service for | ||||||

is poor. There are silvery ar- | low. | instructions on how to adjust | ||||||

eas on dark surfaces which |

|

| temperature. | |||||

are visable or the edges of |

|

|

|

|

| |||

|

|

|

|

| ||||

the image are not sealed | The Speed is too fast. | If using the ‘Rabbit’ speed, | ||||||

well. |

|

| try the ‘Turtle’ speed. Other- | |||||

|

|

|

|

|

| wise contact Technical Ser- | ||

|

|

|

|

|

| vice for instructions on how | ||

|

|

|

|

|

| to adjust speed. | ||

|

|

|

|

|

|

| ||

|

|

|

| The Roller pressure is too | Adjust the setting on the | |||

|

|

|

| low. | Roller Gap Control to the | |||

|

|

|

|

|

| next narrower setting. | ||

|

|

|

|

|

|

|

|

|

The quality of the lamination | The Roller temperature is too | Contact Technical Service for | ||||||

shows bubbles or ripples. | high. | instructions on how to adjust | ||||||

|

|

|

|

|

| temperature. | ||

|

|

|

|

|

|

| ||

|

|

|

| The Speed is too slow. | If using the ‘Turtle’ speed, | |||

|

|

|

|

|

| try the ‘rabbit’ speed. Other- | ||

|

|

|

|

|

| wise contact Technical Ser- | ||

|

|

|

|

|

| vice for instructions on how | ||

|

|

|

|

|

| to adjust speed. | ||

|

|

|

|

|

|

| ||

|

|

|

| There is too much pressure. | Adjust the setting on the | |||

|

|

|

|

|

| Roller Gap Control to the | ||

|

|

|

|

|

| next thicker setting. | ||

|

|

|

|

|

|

|

|

|

There are wrinkles in either | There is too much pressure. | Adjust the setting on the | ||||||

the flexible pouch or pouch |

|

| Roller Gap Control to the | |||||

board. |

|

| next thicker setting. | |||||

|

|

|

|

|

|

| ||

|

|

|

| The seal of the leading edge | ||||

|

|

|

| is not smooth. | edge smoothly | |||

|

|

|

|

|

|

|

|

|

PHOENIX 44 LAMINATOR | 15 |

|

|