INSTALLATION

Continued

CHECKING GAS CONNECTIONS

![]() WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

![]() WARNING:Neveruseanopen flame to check for a leak. Apply a noncorrosive leak detection fluid toalljoints.Bubblesformingshow a leak. Correct all leaks at once.

WARNING:Neveruseanopen flame to check for a leak. Apply a noncorrosive leak detection fluid toalljoints.Bubblesformingshow a leak. Correct all leaks at once.

PRESSURE TESTING GAS SUPPLY PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1.Disconnect log set and its individual equipment shutoff valve from gas supply piping system.

2.Cap off open end of gas pipe where equipment shutoff valve was connected.

3.Pressurize supply piping system by either us- ing compressed air or opening main gas valve located on or near gas meter.

4.Check all joints of gas supply piping system. Apply noncorrosive leak detection fluid to gas joints. Bubbles forming show a leak.

5.Correct all leaks at once.

6.Reconnect log set and equipment shutoff valve to gas supply. Check reconnected fit- tings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

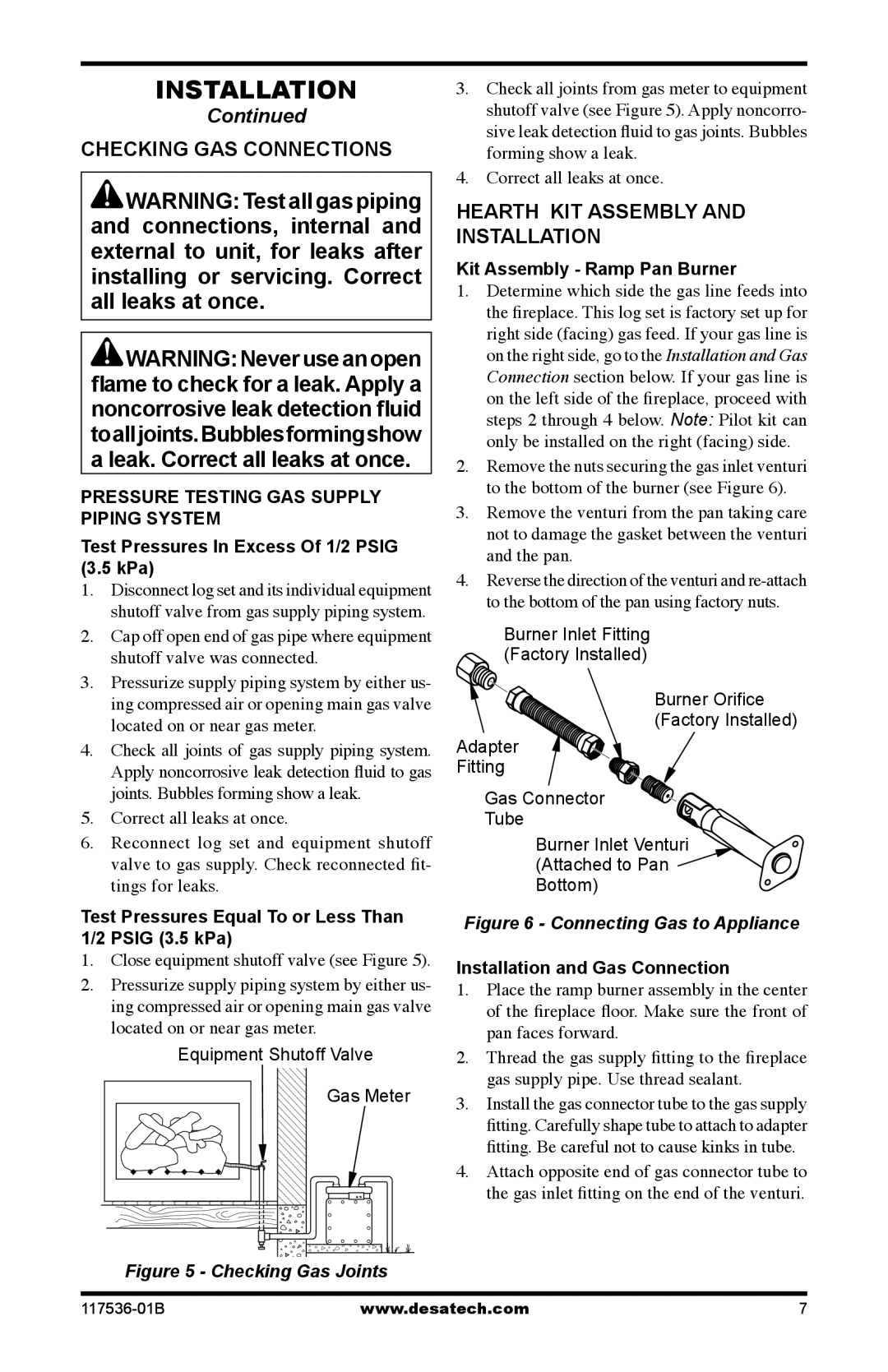

1.Close equipment shutoff valve (see Figure 5).

2.Pressurize supply piping system by either us- ing compressed air or opening main gas valve located on or near gas meter.

Equipment Shutoff Valve

Gas Meter

3.Check all joints from gas meter to equipment shutoff valve (see Figure 5). Apply noncorro- sive leak detection fluid to gas joints. Bubbles forming show a leak.

4.Correct all leaks at once.

HEARTH KIT ASSEMBLY AND INSTALLATION

Kit Assembly - Ramp Pan Burner

1.Determine which side the gas line feeds into the fireplace. This log set is factory set up for right side (facing) gas feed. If your gas line is on the right side, go to the Installation and Gas Connection section below. If your gas line is on the left side of the fireplace, proceed with steps 2 through 4 below. Note: Pilot kit can only be installed on the right (facing) side.

2.Remove the nuts securing the gas inlet venturi to the bottom of the burner (see Figure 6).

3.Remove the venturi from the pan taking care not to damage the gasket between the venturi and the pan.

4.Reverse the direction of the venturi and

Burner Inlet Fitting

(Factory Installed)

Burner Orifice

(Factory Installed)

Adapter

Fitting

Gas Connector

Tube

Burner Inlet Venturi (Attached to Pan ![]() Bottom)

Bottom)

Figure 6 - Connecting Gas to Appliance Installation and Gas Connection

1.Place the ramp burner assembly in the center of the fireplace floor. Make sure the front of pan faces forward.

2.Thread the gas supply fitting to the fireplace gas supply pipe. Use thread sealant.

3.Install the gas connector tube to the gas supply fitting. Carefully shape tube to attach to adapter fitting. Be careful not to cause kinks in tube.

4.Attach opposite end of gas connector tube to

the gas inlet fitting on the end of the venturi.

Figure 5 - Checking Gas Joints

www.desatech.com | 7 |