4.To adjust belt tension, turn nuts (F) and (G) Fig. 34, to move motor plate (H) up or down until there is approximately 1/2 inch deflection at the center span of the belts, as explained in STEP 3.

ADJUSTING SPRING TENSION OF CUTTERHEAD GUARD

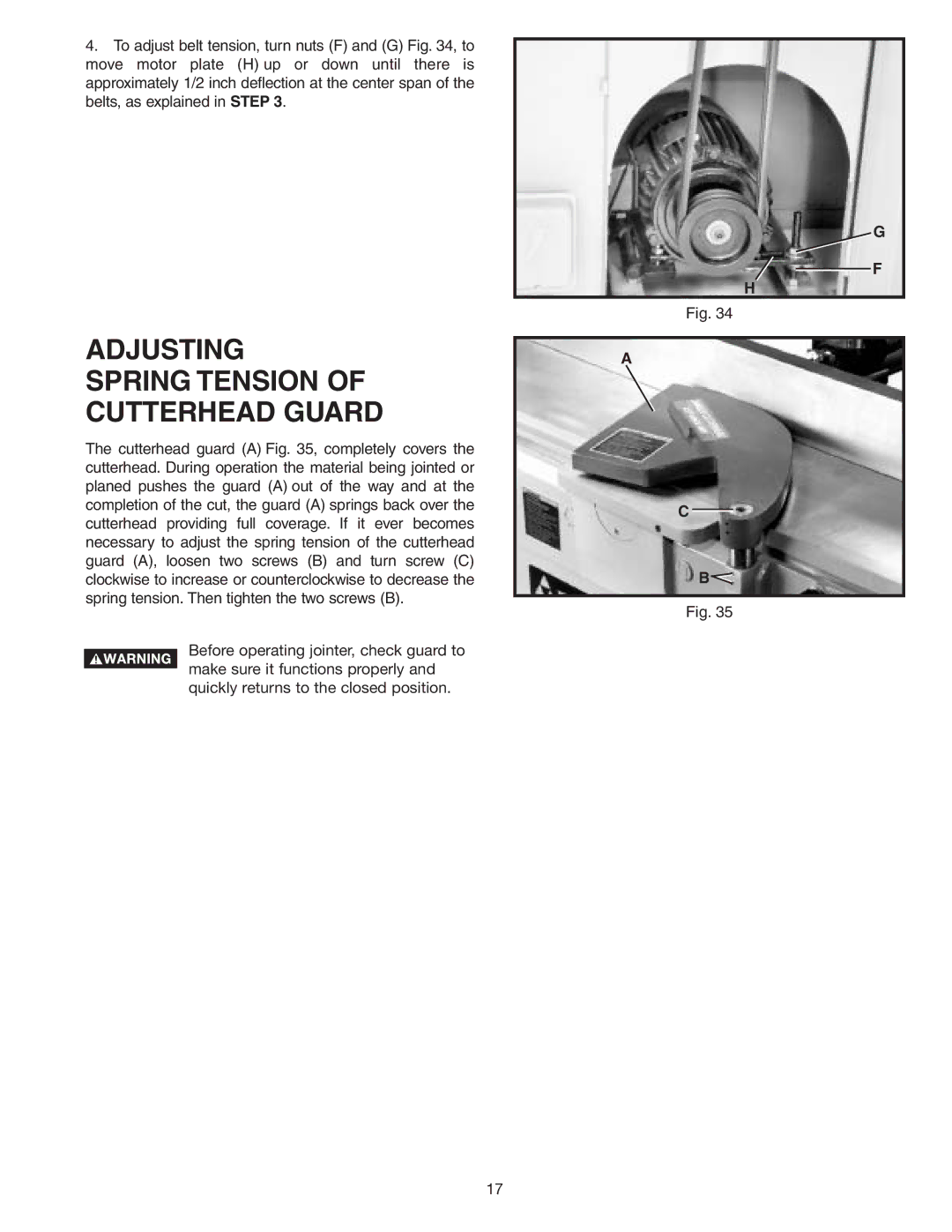

The cutterhead guard (A) Fig. 35, completely covers the cutterhead. During operation the material being jointed or planed pushes the guard (A) out of the way and at the completion of the cut, the guard (A) springs back over the cutterhead providing full coverage. If it ever becomes necessary to adjust the spring tension of the cutterhead guard (A), loosen two screws (B) and turn screw (C) clockwise to increase or counterclockwise to decrease the spring tension. Then tighten the two screws (B).

Before operating jointer, check guard to make sure it functions properly and quickly returns to the closed position.

G

F

H

Fig. 34

A

C

B![]()

Fig. 35

17