DEFINITIONS OF JOINTING AND PLANING OPERATIONS

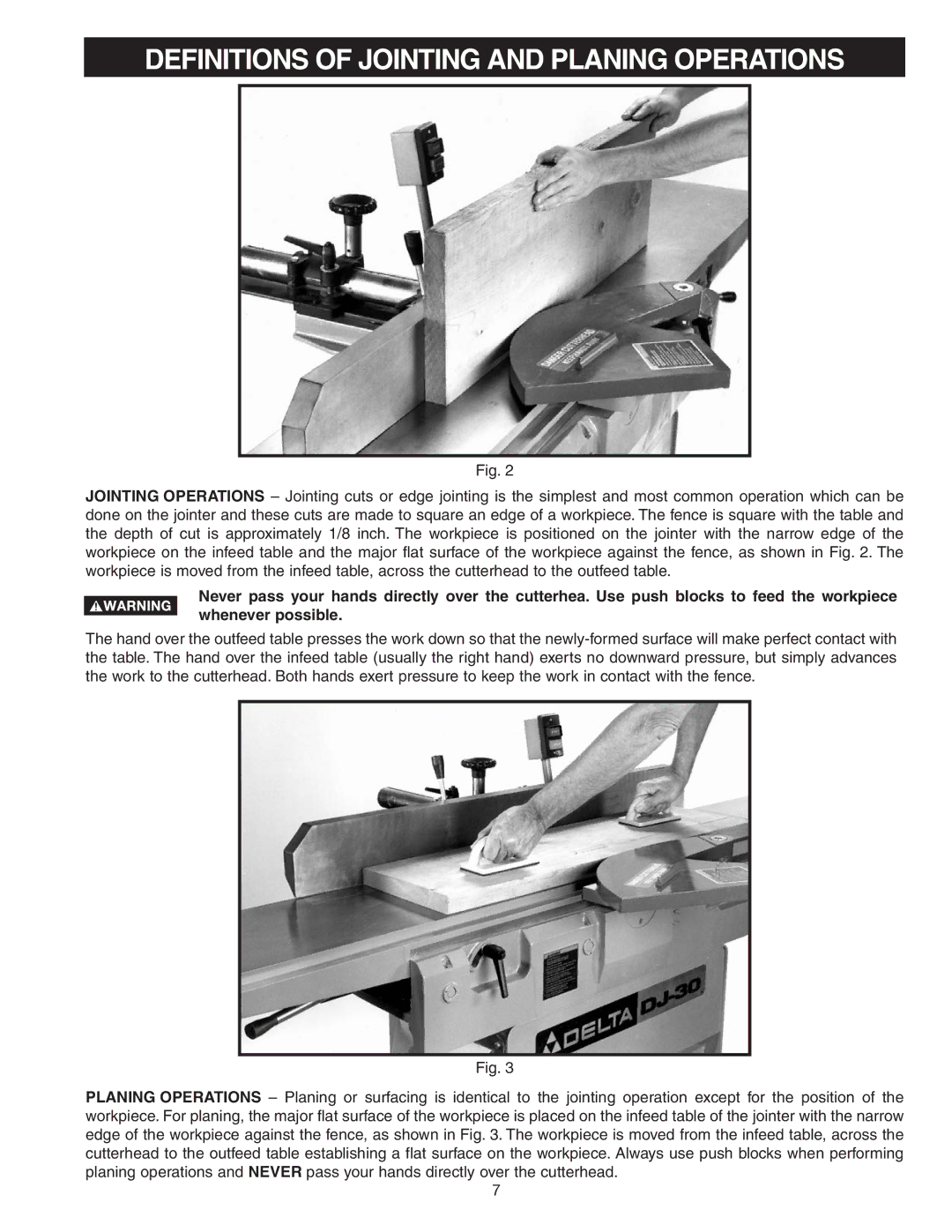

Fig. 2

JOINTING OPERATIONS – Jointing cuts or edge jointing is the simplest and most common operation which can be done on the jointer and these cuts are made to square an edge of a workpiece. The fence is square with the table and the depth of cut is approximately 1/8 inch. The workpiece is positioned on the jointer with the narrow edge of the workpiece on the infeed table and the major flat surface of the workpiece against the fence, as shown in Fig. 2. The workpiece is moved from the infeed table, across the cutterhead to the outfeed table.

Never pass your hands directly over the cutterhea. Use push blocks to feed the workpiece whenever possible.

The hand over the outfeed table presses the work down so that the

Fig. 3

PLANING OPERATIONS – Planing or surfacing is identical to the jointing operation except for the position of the workpiece. For planing, the major flat surface of the workpiece is placed on the infeed table of the jointer with the narrow edge of the workpiece against the fence, as shown in Fig. 3. The workpiece is moved from the infeed table, across the cutterhead to the outfeed table establishing a flat surface on the workpiece. Always use push blocks when performing planing operations and NEVER pass your hands directly over the cutterhead.

7