English

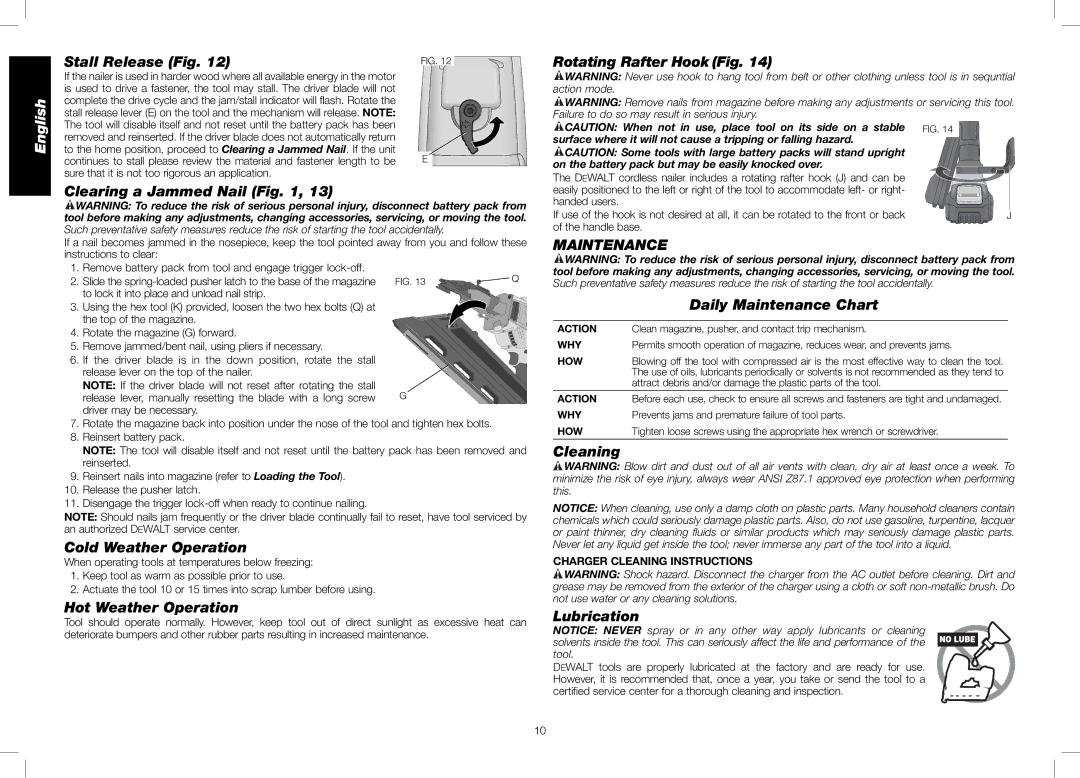

Stall Release (Fig. 12)

If the nailer is used in harder wood where all available energy in the motor is used to drive a fastener, the tool may stall. The driver blade will not complete the drive cycle and the jam/stall indicator will flash. Rotate the stall release lever (E) on the tool and the mechanism will release. NOTE: The tool will disable itself and not reset until the battery pack has been removed and reinserted. If the driver blade does not automatically return to the home position, proceed to Clearing a Jammed Nail. If the unit continues to stall please review the material and fastener length to be sure that it is not too rigorous an application.

FIG. 12

E ![]()

Rotating Rafter Hook (Fig. 14)

![]() WARNING: Never use hook to hang tool from belt or other clothing unless tool is in sequntial action mode.

WARNING: Never use hook to hang tool from belt or other clothing unless tool is in sequntial action mode.

![]() WARNING: Remove nails from magazine before making any adjustments or servicing this tool. Failure to do so may result in serious injury.

WARNING: Remove nails from magazine before making any adjustments or servicing this tool. Failure to do so may result in serious injury.

CAUTION: When not in use, place tool on its side on a stable FIG. 14 |

surface where it will not cause a tripping or falling hazard. |

CAUTION: Some tools with large battery packs will stand upright |

on the battery pack but may be easily knocked over. |

The DEWALT cordless nailer includes a rotating rafter hook (J) and can be |

Clearing a Jammed Nail (Fig. 1, 13)

![]() WARNING: To reduce the risk of serious personal injury, disconnect battery pack from tool before making any adjustments, changing accessories, servicing, or moving the tool.

WARNING: To reduce the risk of serious personal injury, disconnect battery pack from tool before making any adjustments, changing accessories, servicing, or moving the tool.

Such preventative safety measures reduce the risk of starting the tool accidentally.

If a nail becomes jammed in the nosepiece, keep the tool pointed away from you and follow these instructions to clear:

1. | Remove battery pack from tool and engage trigger |

| Q |

2. | Slide the | FIG. 13 | |

| to lock it into place and unload nail strip. |

|

|

3. | Using the hex tool (K) provided, loosen the two hex bolts (Q) at |

|

|

| the top of the magazine. |

|

|

4. | Rotate the magazine (G) forward. |

|

|

5. | Remove jammed/bent nail, using pliers if necessary. |

|

|

6. | If the driver blade is in the down position, rotate the stall |

|

|

| release lever on the top of the nailer. |

|

|

NOTE: If the driver blade will not reset after rotating the stall release lever, manually resetting the blade with a long screw driver may be necessary.

7.Rotate the magazine back into position under the nose of the tool and tighten hex bolts.

8.Reinsert battery pack.

NOTE: The tool will disable itself and not reset until the battery pack has been removed and reinserted.

9.Reinsert nails into magazine (refer to Loading the Tool).

10.Release the pusher latch.

11.Disengage the trigger

NOTE: Should nails jam frequently or the driver blade continually fail to reset, have tool serviced by an authorized DEWALT service center.

Cold Weather Operation

When operating tools at temperatures below freezing:

1.Keep tool as warm as possible prior to use.

2.Actuate the tool 10 or 15 times into scrap lumber before using.

Hot Weather Operation

Tool should operate normally. However, keep tool out of direct sunlight as excessive heat can deteriorate bumpers and other rubber parts resulting in increased maintenance.

easily positioned to the left or right of the tool to accommodate left- or right- |

|

handed users. |

|

If use of the hook is not desired at all, it can be rotated to the front or back | J |

of the handle base. |

|

MAINTENANCE

![]() WARNING: To reduce the risk of serious personal injury, disconnect battery pack from tool before making any adjustments, changing accessories, servicing, or moving the tool. Such preventative safety measures reduce the risk of starting the tool accidentally.

WARNING: To reduce the risk of serious personal injury, disconnect battery pack from tool before making any adjustments, changing accessories, servicing, or moving the tool. Such preventative safety measures reduce the risk of starting the tool accidentally.

| Daily Maintenance Chart |

|

|

ACTION | Clean magazine, pusher, and contact trip mechanism. |

WHY | Permits smooth operation of magazine, reduces wear, and prevents jams. |

HOW | Blowing off the tool with compressed air is the most effective way to clean the tool. |

| The use of oils, lubricants periodically or solvents is not recommended as they tend to |

| attract debris and/or damage the plastic parts of the tool. |

ACTION | Before each use, check to ensure all screws and fasteners are tight and undamaged. |

WHY | Prevents jams and premature failure of tool parts. |

HOW | Tighten loose screws using the appropriate hex wrench or screwdriver. |

|

|

Cleaning

![]() WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing this.

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing this.

NOTICE: When cleaning, use only a damp cloth on plastic parts. Many household cleaners contain chemicals which could seriously damage plastic parts. Also, do not use gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products which may seriously damage plastic parts. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

![]() WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft

WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft

Lubrication

NOTICE: NEVER spray or in any other way apply lubricants or cleaning solvents inside the tool. This can seriously affect the life and performance of the tool.

DEWALT tools are properly lubricated at the factory and are ready for use. However, it is recommended that, once a year, you take or send the tool to a certified service center for a thorough cleaning and inspection.

10