OPERATION

OPERATIONAL CONTROLS AND ADJUSTMENTS

STARTING AND STOPPING THE LATHE |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

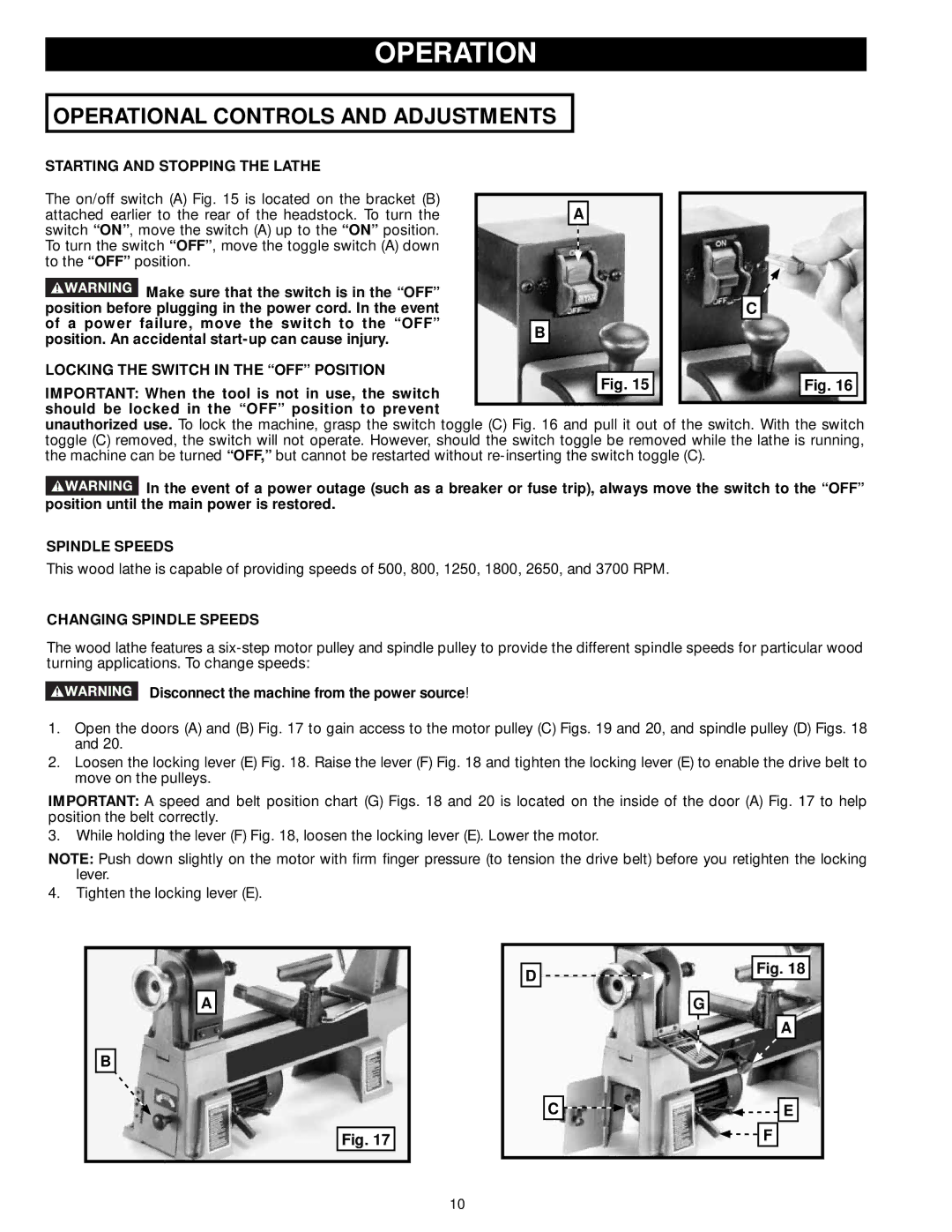

The on/off switch (A) Fig. 15 is located on the bracket (B) |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| A |

|

|

|

|

|

|

|

|

| ||||

attached earlier to the rear of the headstock. To turn the |

|

|

|

|

|

|

|

|

|

|

|

| ||||

switch “ON”, move the switch (A) up to the “ON” position. |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

To turn the switch “OFF”, move the toggle switch (A) down |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

to the “OFF” position. |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

| Make sure that the switch is in the “OFF” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

position before plugging in the power cord. In the event |

|

|

|

|

|

|

|

|

| C |

|

|

| |||

of a power failure, move the switch to the “OFF” |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| B |

|

|

|

|

|

|

|

|

|

|

| ||||

position. An accidental |

|

|

|

|

|

|

|

|

|

| ||||||

LOCKING THE SWITCH IN THE “OFF” POSITION |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| Fig. 15 |

|

|

|

|

| Fig. 16 |

| ||||

IMPORTANT: When the tool is not in use, the switch |

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

should be locked in the “OFF” position to prevent |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

unauthorized use. To lock the machine, grasp the switch toggle (C) Fig. 16 and pull it out of the switch. With the switch toggle (C) removed, the switch will not operate. However, should the switch toggle be removed while the lathe is running, the machine can be turned “OFF,” but cannot be restarted without

![]() In the event of a power outage (such as a breaker or fuse trip), always move the switch to the “OFF” position until the main power is restored.

In the event of a power outage (such as a breaker or fuse trip), always move the switch to the “OFF” position until the main power is restored.

SPINDLE SPEEDS

This wood lathe is capable of providing speeds of 500, 800, 1250, 1800, 2650, and 3700 RPM.

CHANGING SPINDLE SPEEDS

The wood lathe features a

Disconnect the machine from the power source!

1.Open the doors (A) and (B) Fig. 17 to gain access to the motor pulley (C) Figs. 19 and 20, and spindle pulley (D) Figs. 18 and 20.

2.Loosen the locking lever (E) Fig. 18. Raise the lever (F) Fig. 18 and tighten the locking lever (E) to enable the drive belt to move on the pulleys.

IMPORTANT: A speed and belt position chart (G) Figs. 18 and 20 is located on the inside of the door (A) Fig. 17 to help position the belt correctly.

3.While holding the lever (F) Fig. 18, loosen the locking lever (E). Lower the motor.

NOTE: Push down slightly on the motor with firm finger pressure (to tension the drive belt) before you retighten the locking lever.

4.Tighten the locking lever (E).

A

B

Fig. 17

|

| Fig. 18 | |

D | |||

|

| ||

|

|

|

G

A

C | E |

![]()

![]() F

F

10