The alternate position is a

SMOOTHING A CYLINDER

To smooth a cylinder, use a large skew chisel. This requires practice, but experience with this tool is very important. Place the cutting point near the center of chisel and high on the workpiece (Fig. A13). Sometimes, in striving for a certain position in relation to the workpiece, the beginner will often overlook this

USING THE PARTING TOOL

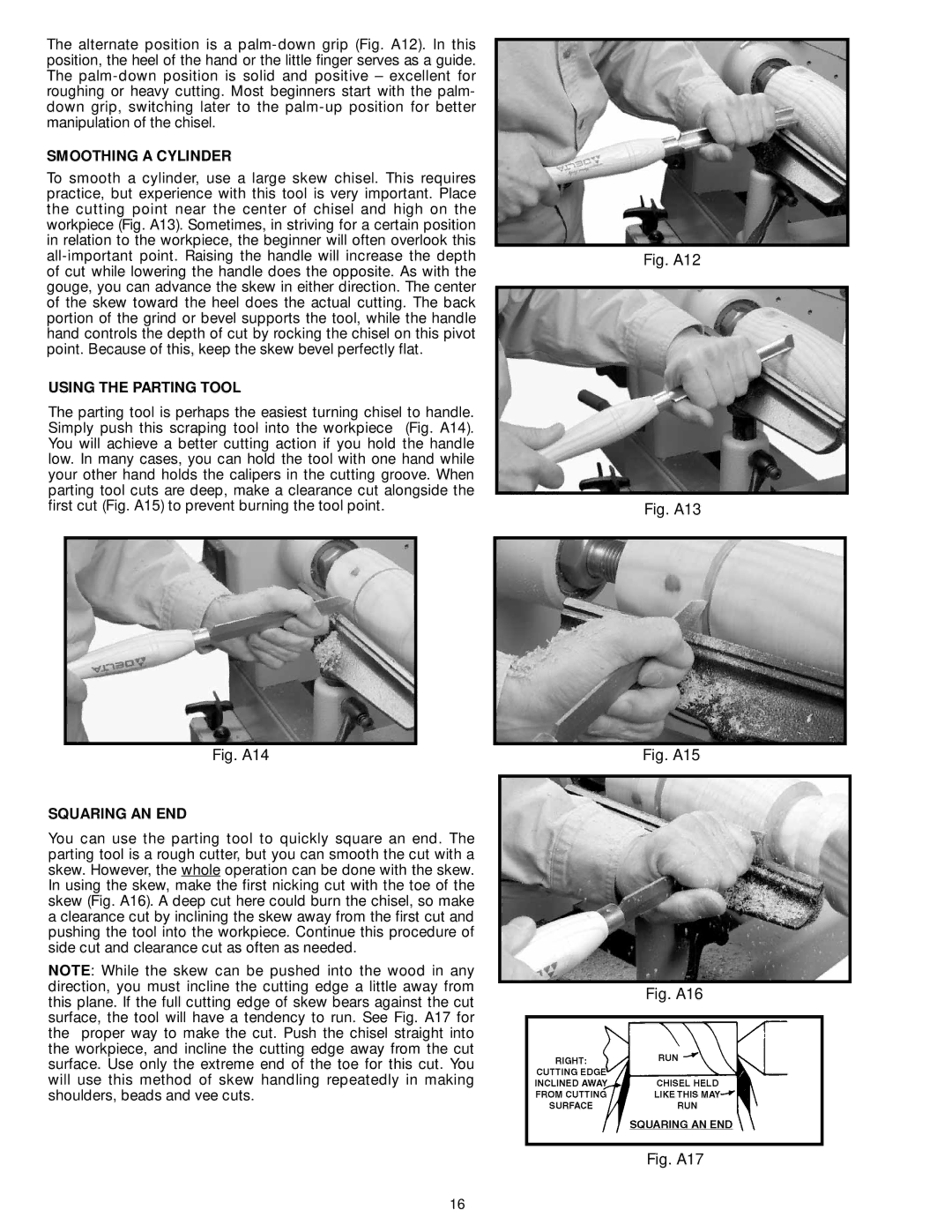

The parting tool is perhaps the easiest turning chisel to handle. Simply push this scraping tool into the workpiece (Fig. A14). You will achieve a better cutting action if you hold the handle low. In many cases, you can hold the tool with one hand while your other hand holds the calipers in the cutting groove. When parting tool cuts are deep, make a clearance cut alongside the first cut (Fig. A15) to prevent burning the tool point.

Fig. A14

SQUARING AN END

You can use the parting tool to quickly square an end. The parting tool is a rough cutter, but you can smooth the cut with a skew. However, the whole operation can be done with the skew. In using the skew, make the first nicking cut with the toe of the skew (Fig. A16). A deep cut here could burn the chisel, so make a clearance cut by inclining the skew away from the first cut and pushing the tool into the workpiece. Continue this procedure of side cut and clearance cut as often as needed.

NOTE: While the skew can be pushed into the wood in any direction, you must incline the cutting edge a little away from this plane. If the full cutting edge of skew bears against the cut surface, the tool will have a tendency to run. See Fig. A17 for the proper way to make the cut. Push the chisel straight into the workpiece, and incline the cutting edge away from the cut surface. Use only the extreme end of the toe for this cut. You will use this method of skew handling repeatedly in making shoulders, beads and vee cuts.

Fig. A12

Fig. A13

Fig. A15

Fig. A16

Fig. A17

16