RaceAmerica Model 3220 Timer SBD

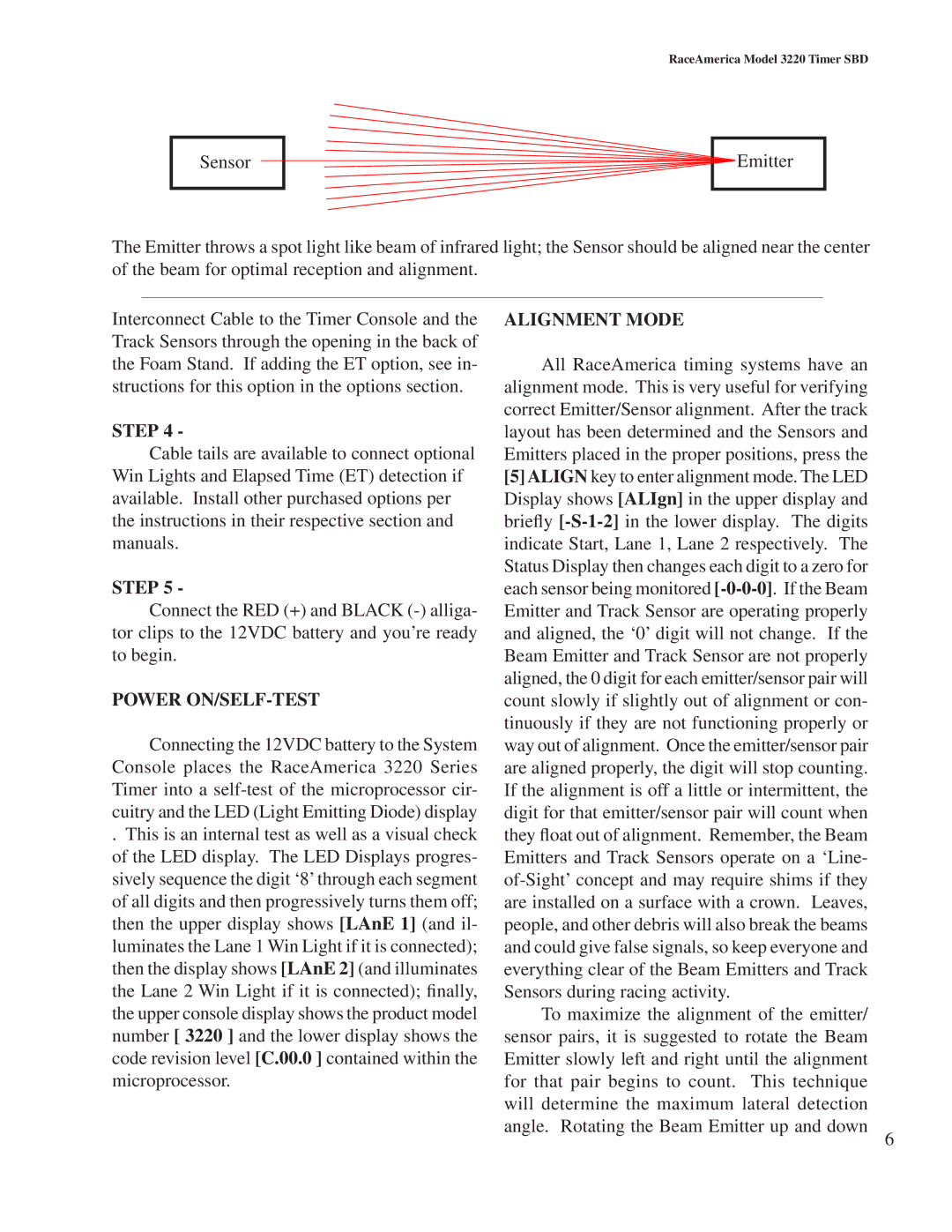

Sensor

Emitter

Emitter

The Emitter throws a spot light like beam of infrared light; the Sensor should be aligned near the center of the beam for optimal reception and alignment.

Interconnect Cable to the Timer Console and the Track Sensors through the opening in the back of the Foam Stand. If adding the ET option, see in- structions for this option in the options section.

STEP 4 -

Cable tails are available to connect optional Win Lights and Elapsed Time (ET) detection if available. Install other purchased options per the instructions in their respective section and manuals.

STEP 5 -

Connect the RED (+) and BLACK

POWER ON/SELF-TEST

Connecting the 12VDC battery to the System Console places the RaceAmerica 3220 Series Timer into a

. This is an internal test as well as a visual check of the LED display. The LED Displays progres- sively sequence the digit ‘8’ through each segment of all digits and then progressively turns them off; then the upper display shows [LAnE 1] (and il- luminates the Lane 1 Win Light if it is connected); then the display shows [LAnE 2] (and illuminates the Lane 2 Win Light if it is connected); finally, the upper console display shows the product model number [ 3220 ] and the lower display shows the code revision level [C.00.0 ] contained within the microprocessor.

ALIGNMENT MODE

All RaceAmerica timing systems have an alignment mode. This is very useful for verifying correct Emitter/Sensor alignment. After the track layout has been determined and the Sensors and Emitters placed in the proper positions, press the

[5]ALIGN key to enter alignment mode. The LED Display shows [ALIgn] in the upper display and briefly

To maximize the alignment of the emitter/ sensor pairs, it is suggested to rotate the Beam Emitter slowly left and right until the alignment for that pair begins to count. This technique will determine the maximum lateral detection angle. Rotating the Beam Emitter up and down