SECTION 1 INSTALLATION

Series 300 Automatic Transfer Switches are factory wired and tested. Installation requires skid removal then secur- ing the enclosure to the supporting foundation.

Supporting Foundation

The supporting foundation for the enclosure must be level and straight. Refer to the applicable enclosure outline drawing included with the Series 300 for all mounting details including door opening space.

If bottom cable entry is used, the foundation must be prepared so that the conduit stubs are located correctly. Refer to the enclosure outline drawing for specified area and location. Provide cable bending space and clearance to live metal parts. When a concrete floor is poured, use interlocking conduit spacer caps or a wood or metal template to maintain proper conduit alignment.

Mounting

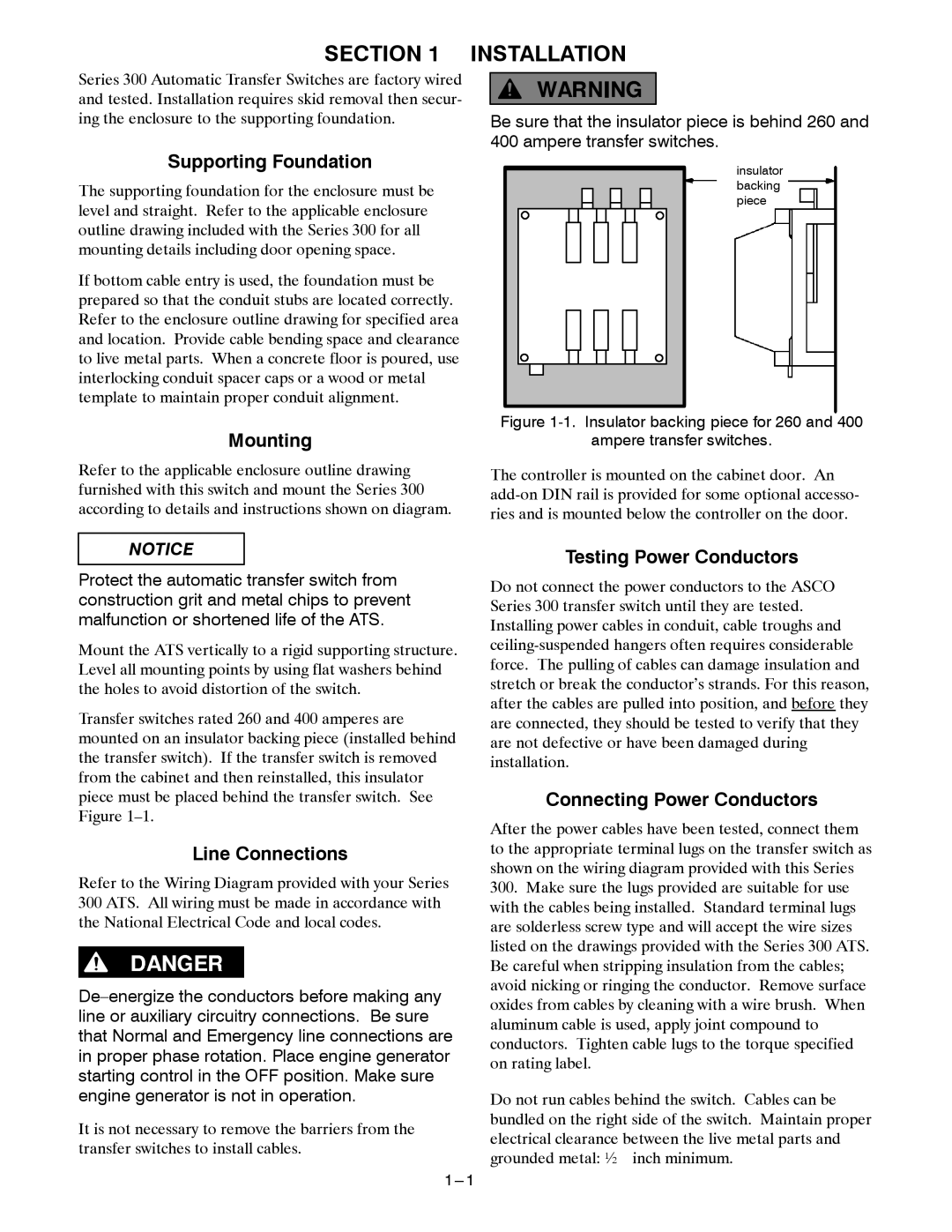

Be sure that the insulator piece is behind 260 and 400 ampere transfer switches.

insulator backing piece

Figure 1-1. Insulator backing piece for 260 and 400

ampere transfer switches.

Refer to the applicable enclosure outline drawing furnished with this switch and mount the Series 300 according to details and instructions shown on diagram.

The controller is mounted on the cabinet door. An

NOTICE

Protect the automatic transfer switch from construction grit and metal chips to prevent malfunction or shortened life of the ATS.

Mount the ATS vertically to a rigid supporting structure. Level all mounting points by using flat washers behind the holes to avoid distortion of the switch.

Transfer switches rated 260 and 400 amperes are mounted on an insulator backing piece (installed behind the transfer switch). If the transfer switch is removed from the cabinet and then reinstalled, this insulator piece must be placed behind the transfer switch. See Figure

Line Connections

Refer to the Wiring Diagram provided with your Series 300 ATS. All wiring must be made in accordance with the National Electrical Code and local codes.

It is not necessary to remove the barriers from the transfer switches to install cables.

Testing Power Conductors

Do not connect the power conductors to the ASCO Series 300 transfer switch until they are tested. Installing power cables in conduit, cable troughs and

Connecting Power Conductors

After the power cables have been tested, connect them to the appropriate terminal lugs on the transfer switch as shown on the wiring diagram provided with this Series

300.Make sure the lugs provided are suitable for use with the cables being installed. Standard terminal lugs are solderless screw type and will accept the wire sizes listed on the drawings provided with the Series 300 ATS. Be careful when stripping insulation from the cables; avoid nicking or ringing the conductor. Remove surface oxides from cables by cleaning with a wire brush. When aluminum cable is used, apply joint compound to conductors. Tighten cable lugs to the torque specified on rating label.

Do not run cables behind the switch. Cables can be bundled on the right side of the switch. Maintain proper electrical clearance between the live metal parts and grounded metal: ½ inch minimum.