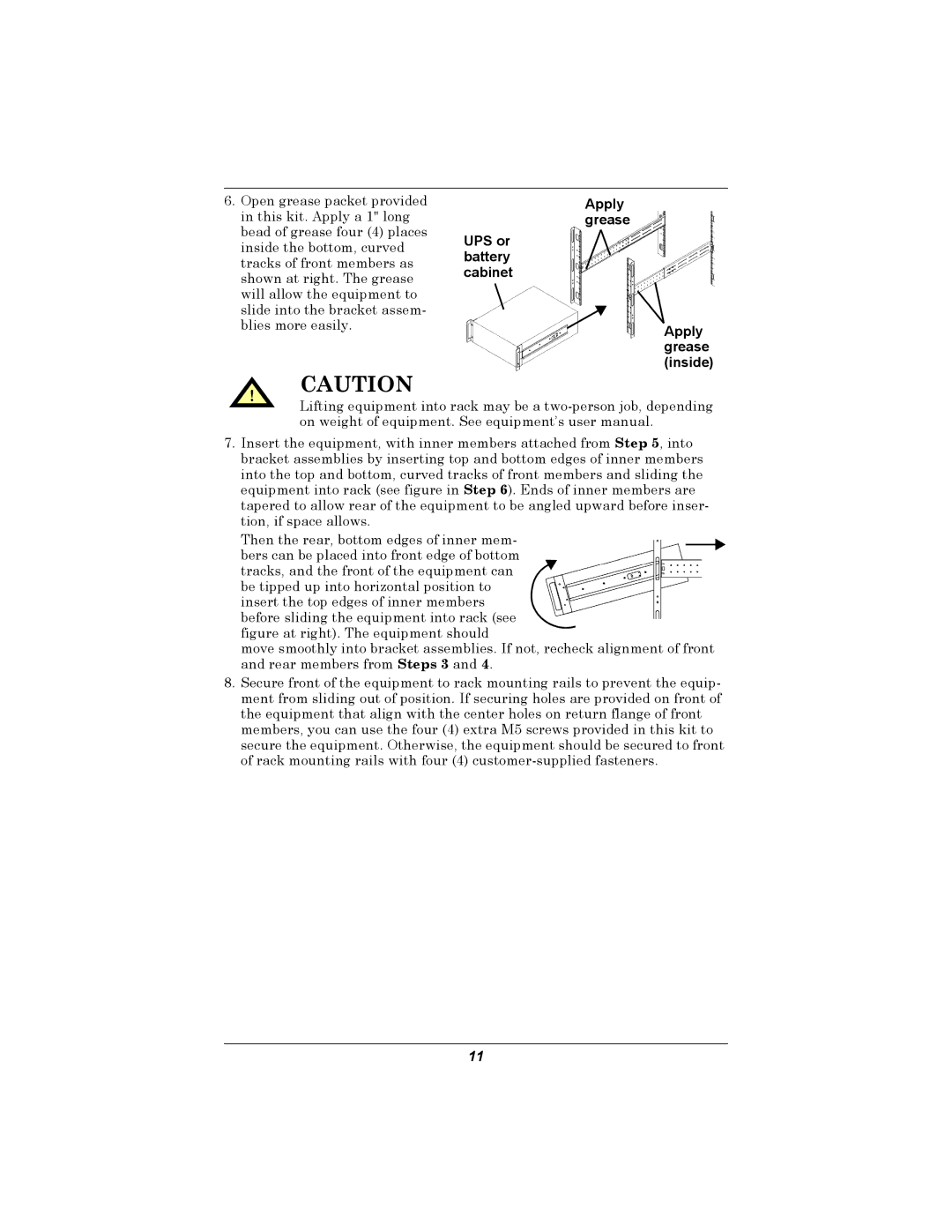

6. Open grease packet provided | Apply |

in this kit. Apply a 1" long | grease |

bead of grease four (4) places | UPS or |

inside the bottom, curved | |

tracks of front members as | battery |

shown at right. The grease | cabinet |

will allow the equipment to |

|

slide into the bracket assem- |

|

blies more easily. | Apply |

| |

| grease |

| (inside) |

! CAUTION

Lifting equipment into rack may be a

7.Insert the equipment, with inner members attached from Step 5, into bracket assemblies by inserting top and bottom edges of inner members into the top and bottom, curved tracks of front members and sliding the equipment into rack (see figure in Step 6). Ends of inner members are tapered to allow rear of the equipment to be angled upward before inser- tion, if space allows.

Then the rear, bottom edges of inner mem-

bers can be placed into front edge of bottom tracks, and the front of the equipment can

be tipped up into horizontal position to insert the top edges of inner members before sliding the equipment into rack (see figure at right). The equipment should

move smoothly into bracket assemblies. If not, recheck alignment of front and rear members from Steps 3 and 4.

8.Secure front of the equipment to rack mounting rails to prevent the equip- ment from sliding out of position. If securing holes are provided on front of the equipment that align with the center holes on return flange of front members, you can use the four (4) extra M5 screws provided in this kit to secure the equipment. Otherwise, the equipment should be secured to front of rack mounting rails with four (4)

11