MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

![]() Wear ANSI Z87.1 safety glasses while using compressed air.

Wear ANSI Z87.1 safety glasses while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

PROTECTING CAST IRON FROM RUST

To clean and protect cast iron tables from rust, you will need the following materials: 1 pushblock from a jointer, 1 sheet of medium

LUBRICATION

The gear box oil should be changed once a year. Use extreme pressure gear oil, available from Delta in one pint cans (you will need approximately 20 oz.). The gear box drain plug is shown at (A) Fig. 53. The oil fill and level plug is shown at (B) Fig. 54.

The four raising screws, two of which are shown at (C) Fig. 55, should be lubricated as required using a common grease.

Periodically remove screw (D) Fig. 55, and side cover (E). Thoroughly clean chains and sprockets (F) Fig. 56, and lubricate using a light (10W) machine oil. Replace side cover (E) Fig. 55, and secure with screw (D).

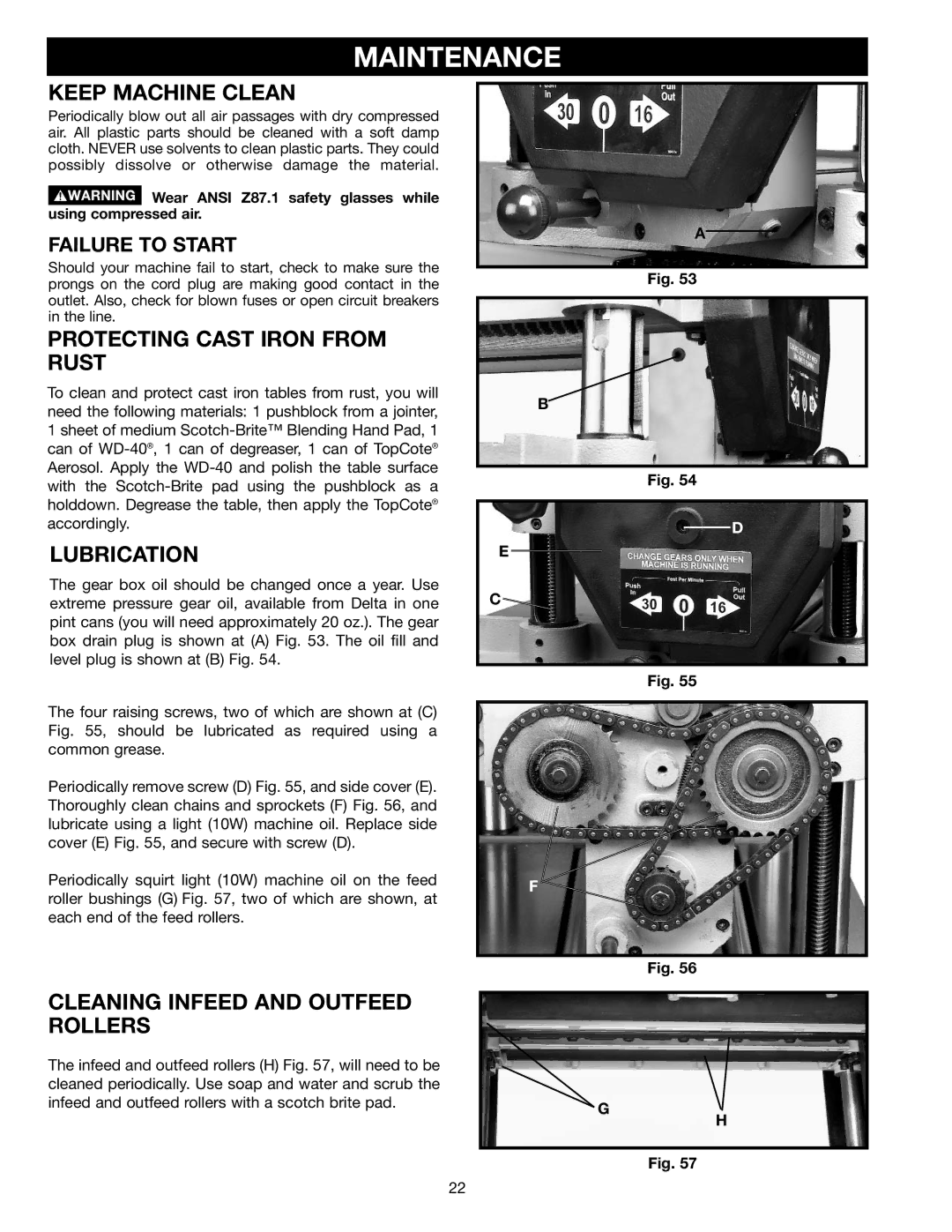

Periodically squirt light (10W) machine oil on the feed roller bushings (G) Fig. 57, two of which are shown, at each end of the feed rollers.

A

Fig. 53

B

Fig. 54

D

E

C![]()

Fig. 55

F ![]()

Fig. 56

CLEANING INFEED AND OUTFEED

ROLLERS

The infeed and outfeed rollers (H) Fig. 57, will need to be |

|

cleaned periodically. Use soap and water and scrub the |

|

infeed and outfeed rollers with a scotch brite pad. | G |

|

H

Fig. 57

22