5.1.21Mobil HTS grease (or

a)Between the cutter housing spindle and bearings.

b)Between the cutter housing spindle and sheave.

c)Under top cutter housing bearing guard.

5.1.22Dielectric grease is used on all blade type electrical connections to prevent corrosion and loss of contact.

5.2ADJUSTMENTS

5.2.1Cutting height and

WARNING

POTENTIAL HAZARD

♦When the two front support rod hairpins are removed from the mower deck, the weight of the tractor section may cause the front frame to rise suddenly

WHAT CAN HAPPEN

♦If the unit rises suddenly, injury may occur.

HOW TO AVOID THE HAZARD

♦Securely hold down the front of the unit when the front support rod hairpins are removed.

a)Stop engine, wait for all moving parts to stop, and remove key or spark plug wire(s).

b)Install hairpin clips in the holes shown on sketch below for the desired cutting height (See Figure 13).

IMPORTANT: To maintain correct cutting height and rake, check the following for proper adjustment.

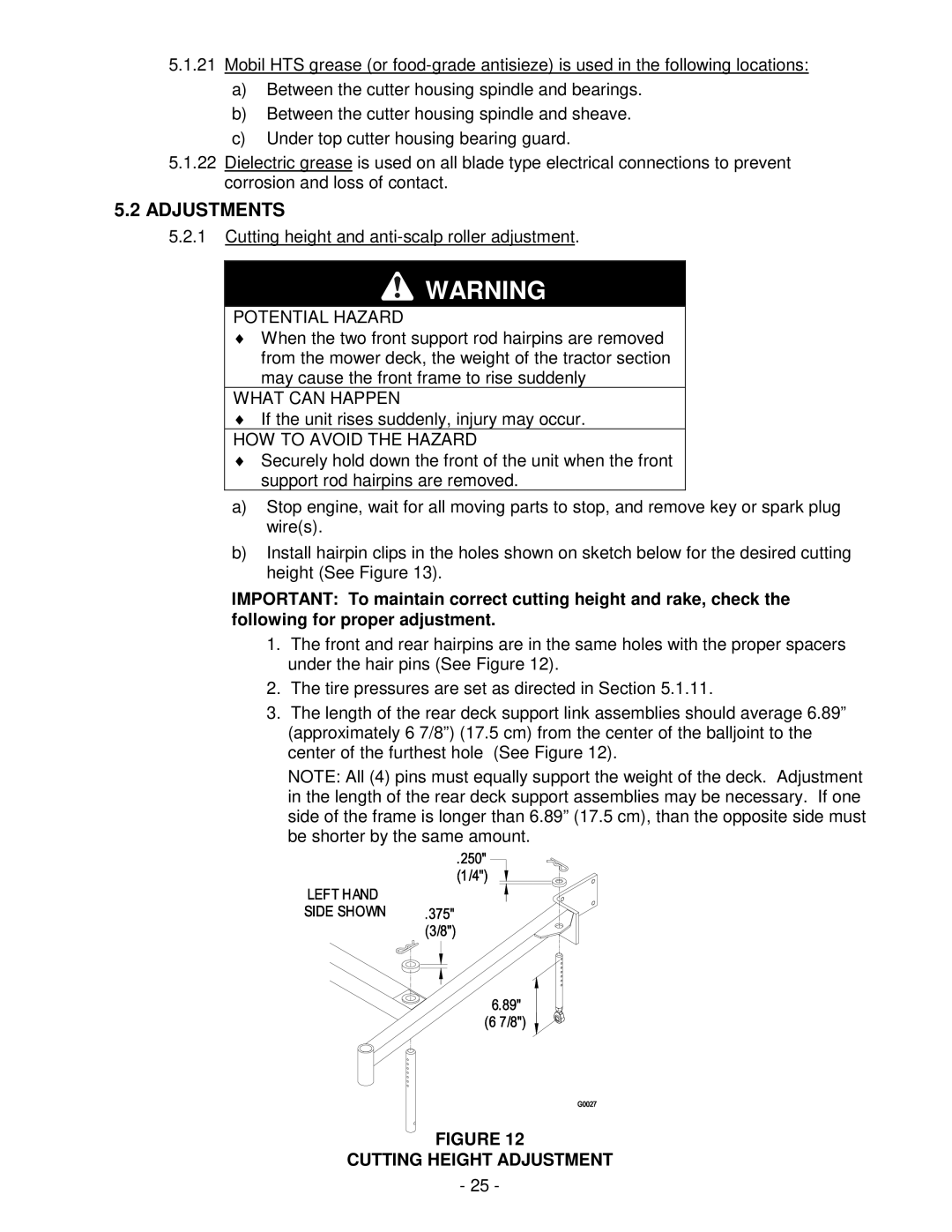

1.The front and rear hairpins are in the same holes with the proper spacers under the hair pins (See Figure 12).

2.The tire pressures are set as directed in Section 5.1.11.

3.The length of the rear deck support link assemblies should average 6.89” (approximately 6 7/8”) (17.5 cm) from the center of the balljoint to the center of the furthest hole (See Figure 12).

NOTE: All (4) pins must equally support the weight of the deck. Adjustment in the length of the rear deck support assemblies may be necessary. If one side of the frame is longer than 6.89” (17.5 cm), than the opposite side must be shorter by the same amount.

FIGURE 12

CUTTING HEIGHT ADJUSTMENT

- 25 -