Basic Routing

Feed Direction Rules

WARNING! To reduce the risk of injury and loss of control, always be aware of the proper router feed direction. The proper router feed direction is a

Operating the router in the correct direction is important for maintaining control over the router. The standard feed direction for routing is that which opposes the cutter’s rotation. This direction affords the operator the most control over the router feed speed. If the router is operated in the reverse direction, the router bit will tend to

To make it easier to remember the standard and reverse feed directions, they are given descriptive names that describe the behavior of the router bit during the cut. These names are

When making a

When making a

The general rule for basic routing is to always feed the router in the

in the Advanced Routing Techniques section on page 14.

Push-Cut Routing

Always feed the router against the rotation of the bit. This helps prevent the router from grabbing the wood and self- feeding, resulting in a loss of control.

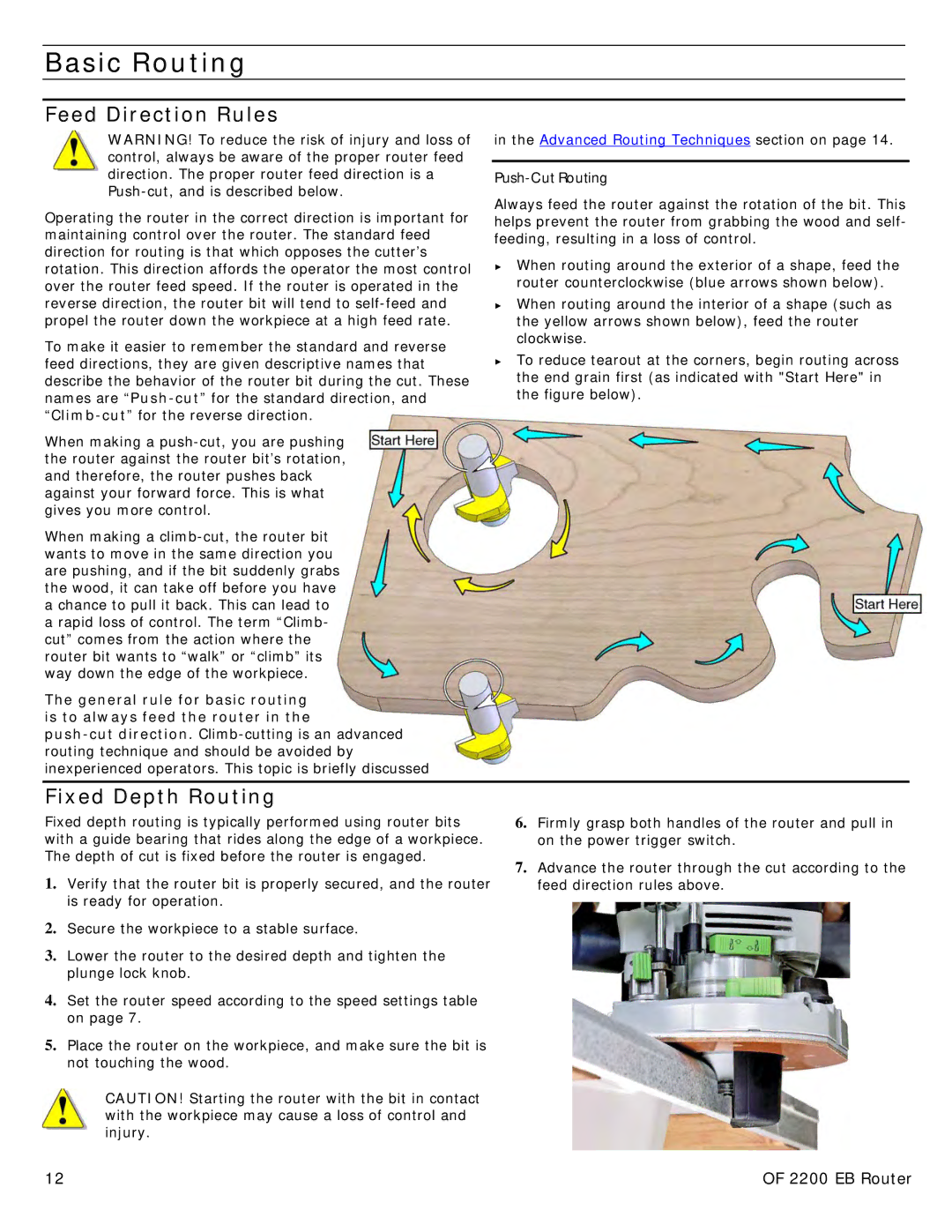

►When routing around the exterior of a shape, feed the router counterclockwise (blue arrows shown below).

►When routing around the interior of a shape (such as the yellow arrows shown below), feed the router clockwise.

►To reduce tearout at the corners, begin routing across the end grain first (as indicated with "Start Here" in the figure below).

Fixed Depth Routing

Fixed depth routing is typically performed using router bits with a guide bearing that rides along the edge of a workpiece. The depth of cut is fixed before the router is engaged.

1.Verify that the router bit is properly secured, and the router is ready for operation.

2.Secure the workpiece to a stable surface.

3.Lower the router to the desired depth and tighten the plunge lock knob.

4.Set the router speed according to the speed settings table on page 7.

5.Place the router on the workpiece, and make sure the bit is not touching the wood.

CAUTION! Starting the router with the bit in contact with the workpiece may cause a loss of control and injury.

6.Firmly grasp both handles of the router and pull in on the power trigger switch.

7.Advance the router through the cut according to the feed direction rules above.

12 | OF 2200 EB Router |