Tips for Successful Routing

Chipping and Tearout

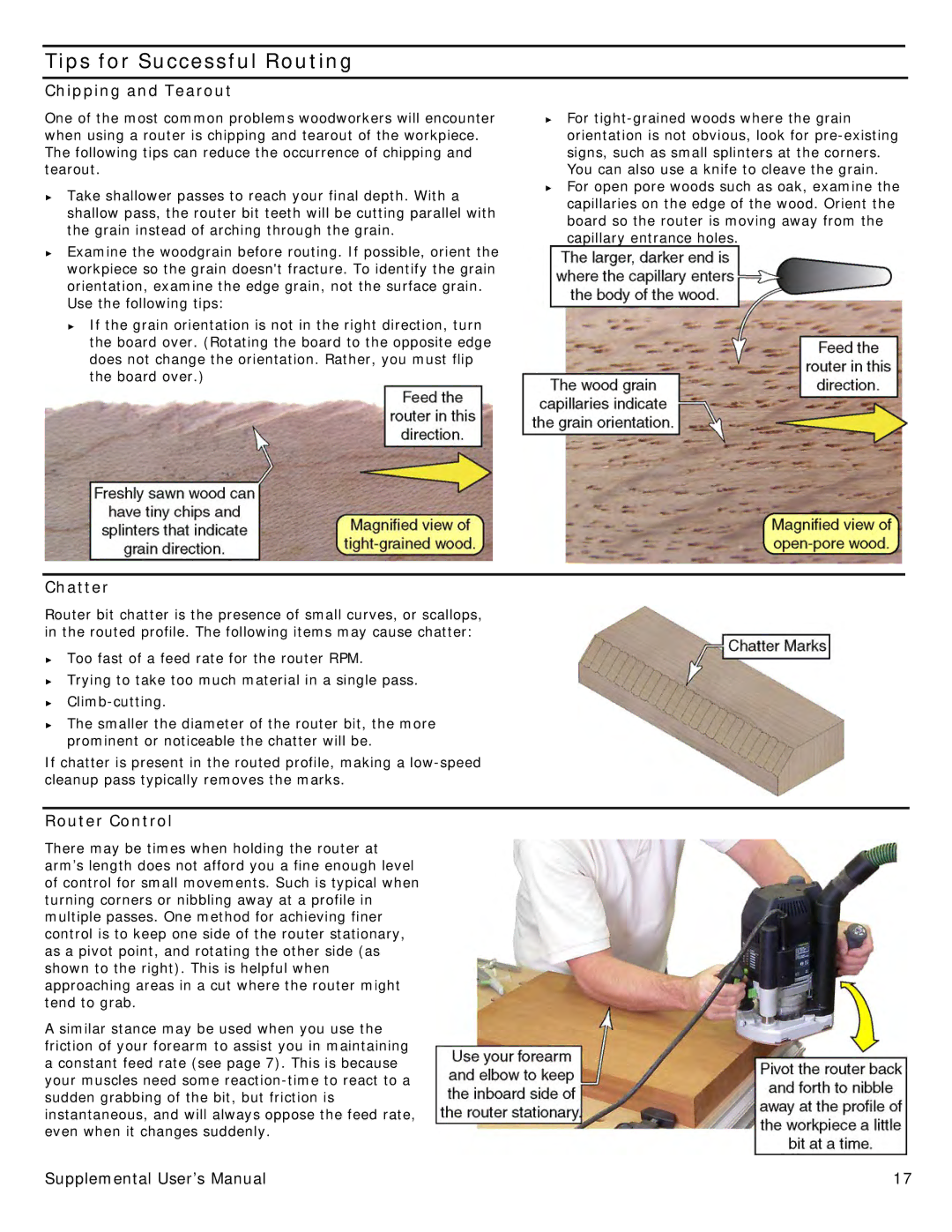

One of the most common problems woodworkers will encounter when using a router is chipping and tearout of the workpiece. The following tips can reduce the occurrence of chipping and tearout.

►Take shallower passes to reach your final depth. With a shallow pass, the router bit teeth will be cutting parallel with the grain instead of arching through the grain.

►Examine the woodgrain before routing. If possible, orient the workpiece so the grain doesn't fracture. To identify the grain orientation, examine the edge grain, not the surface grain.

Use the following tips:

►If the grain orientation is not in the right direction, turn the board over. (Rotating the board to the opposite edge does not change the orientation. Rather, you must flip the board over.)

►For

►For open pore woods such as oak, examine the capillaries on the edge of the wood. Orient the board so the router is moving away from the capillary entrance holes.

Chatter

Router bit chatter is the presence of small curves, or scallops, in the routed profile. The following items may cause chatter:

►Too fast of a feed rate for the router RPM.

►Trying to take too much material in a single pass.

►

►The smaller the diameter of the router bit, the more prominent or noticeable the chatter will be.

If chatter is present in the routed profile, making a

Router Control

There may be times when holding the router at arm’s length does not afford you a fine enough level of control for small movements. Such is typical when turning corners or nibbling away at a profile in multiple passes. One method for achieving finer control is to keep one side of the router stationary, as a pivot point, and rotating the other side (as shown to the right). This is helpful when approaching areas in a cut where the router might tend to grab.

A similar stance may be used when you use the friction of your forearm to assist you in maintaining a constant feed rate (see page 7). This is because your muscles need some

Supplemental User’s Manual | 17 |