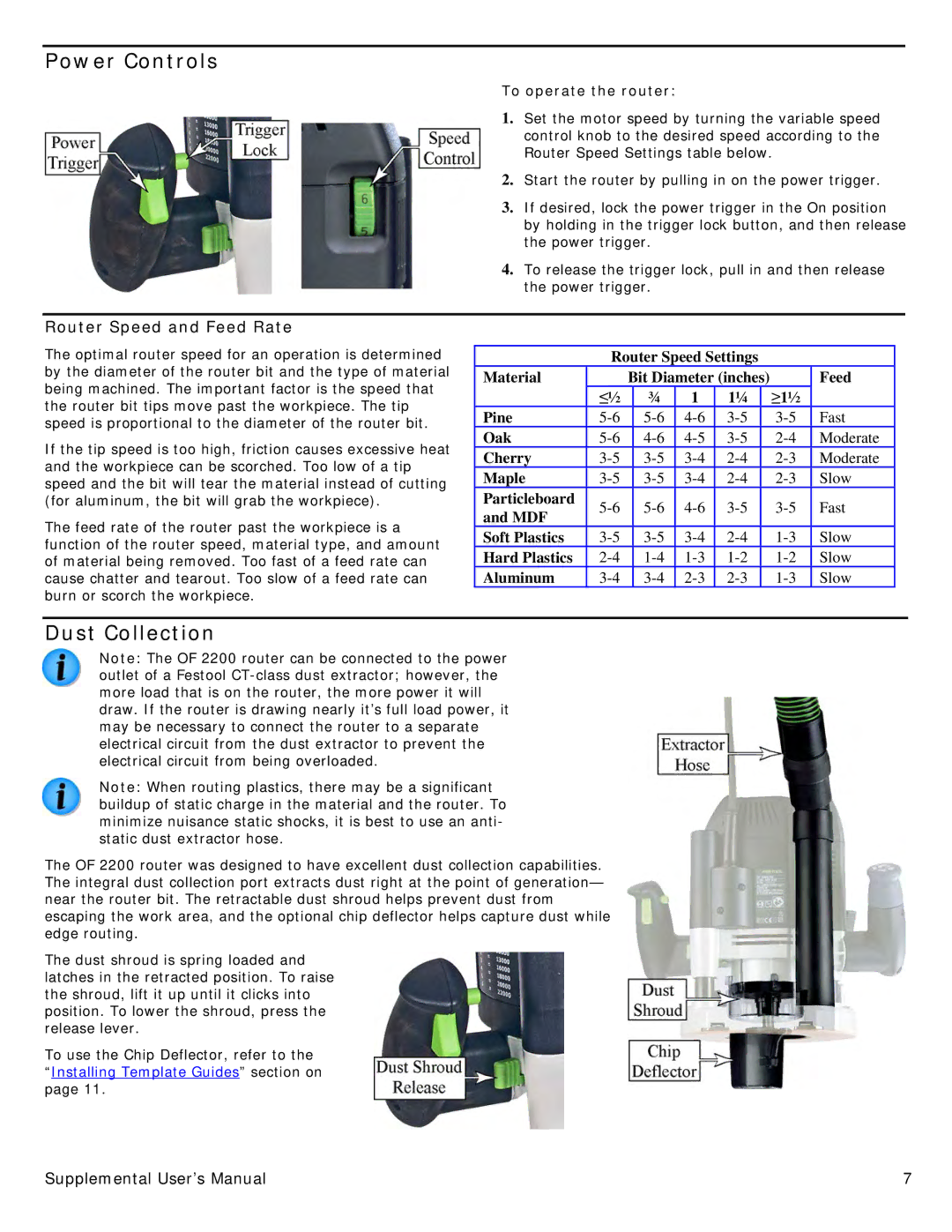

Power Controls

To operate the router:

1. Set the motor speed by turning the variable speed control knob to the desired speed according to the Router Speed Settings table below.

2. Start the router by pulling in on the power trigger.

3. If desired, lock the power trigger in the On position by holding in the trigger lock button, and then release the power trigger.

4. To release the trigger lock, pull in and then release the power trigger.

Router Speed and Feed Rate

The optimal router speed for an operation is determined by the diameter of the router bit and the type of material being machined. The important factor is the speed that the router bit tips move past the workpiece. The tip speed is proportional to the diameter of the router bit.

If the tip speed is too high, friction causes excessive heat and the workpiece can be scorched. Too low of a tip speed and the bit will tear the material instead of cutting (for aluminum, the bit will grab the workpiece).

The feed rate of the router past the workpiece is a function of the router speed, material type, and amount of material being removed. Too fast of a feed rate can cause chatter and tearout. Too slow of a feed rate can burn or scorch the workpiece.

Router Speed Settings

Material |

| Bit Diameter (inches) |

| Feed | ||||

| ≤½ |

| ¾ | 1 | 1¼ |

| ≥1½ |

|

Pine |

|

| Fast | |||||

Oak |

|

| Moderate | |||||

Cherry |

|

| Moderate | |||||

Maple |

|

| Slow | |||||

Particleboard |

|

| Fast | |||||

and MDF |

|

| ||||||

|

|

|

|

|

|

|

| |

Soft Plastics |

|

| Slow | |||||

Hard Plastics |

|

| Slow | |||||

Aluminum |

|

| Slow | |||||

Dust Collection

Note: The OF 2200 router can be connected to the power outlet of a Festool

Note: When routing plastics, there may be a significant buildup of static charge in the material and the router. To minimize nuisance static shocks, it is best to use an anti- static dust extractor hose.

The OF 2200 router was designed to have excellent dust collection capabilities. The integral dust collection port extracts dust right at the point of generation— near the router bit. The retractable dust shroud helps prevent dust from escaping the work area, and the optional chip deflector helps capture dust while edge routing.

The dust shroud is spring loaded and latches in the retracted position. To raise the shroud, lift it up until it clicks into position. To lower the shroud, press the release lever.

To use the Chip Deflector, refer to the “Installing Template Guides” section on page 11.

Supplemental User’s Manual | 7 |