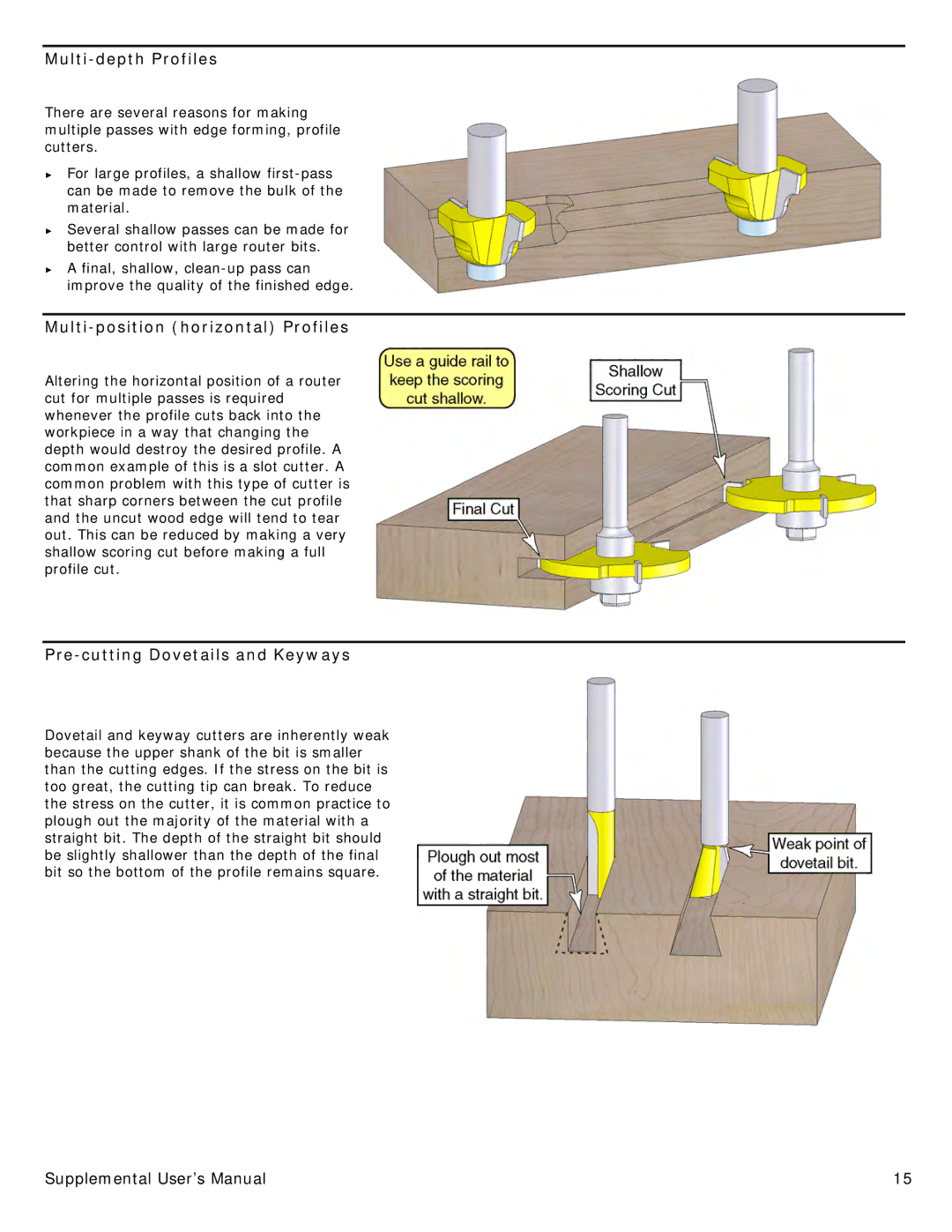

Multi-depth Profiles

There are several reasons for making multiple passes with edge forming, profile cutters.

►For large profiles, a shallow

►Several shallow passes can be made for better control with large router bits.

►A final, shallow,

Multi-position (horizontal) Profiles

Altering the horizontal position of a router cut for multiple passes is required whenever the profile cuts back into the workpiece in a way that changing the depth would destroy the desired profile. A common example of this is a slot cutter. A common problem with this type of cutter is that sharp corners between the cut profile and the uncut wood edge will tend to tear out. This can be reduced by making a very shallow scoring cut before making a full profile cut.

Pre-cutting Dovetails and Keyways

Dovetail and keyway cutters are inherently weak because the upper shank of the bit is smaller than the cutting edges. If the stress on the bit is too great, the cutting tip can break. To reduce the stress on the cutter, it is common practice to plough out the majority of the material with a straight bit. The depth of the straight bit should be slightly shallower than the depth of the final bit so the bottom of the profile remains square.

Supplemental User’s Manual | 15 |