Using a Template Guide

►To install the template guide to the router base, follow the procedure described on page 11.

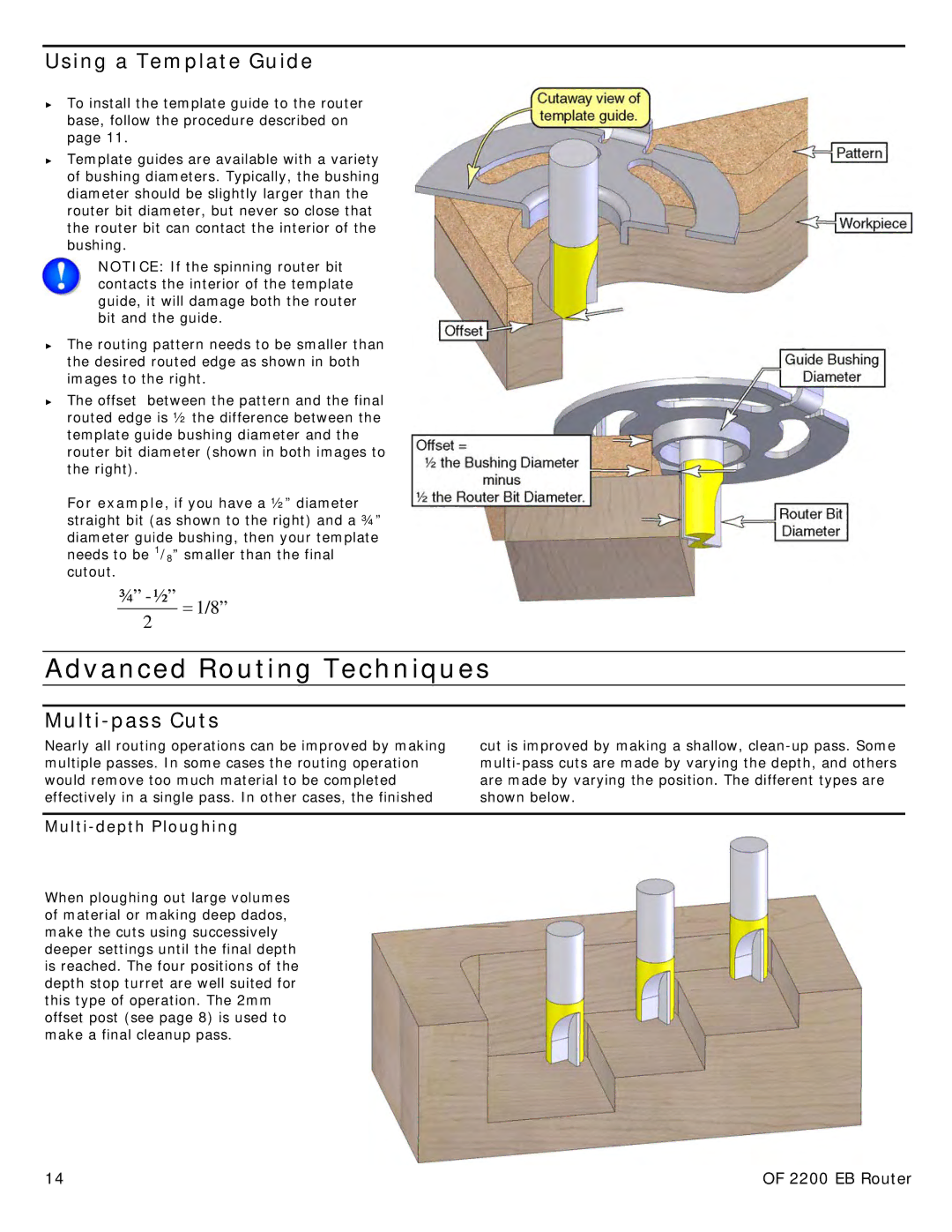

►Template guides are available with a variety of bushing diameters. Typically, the bushing diameter should be slightly larger than the router bit diameter, but never so close that the router bit can contact the interior of the bushing.

NOTICE: If the spinning router bit contacts the interior of the template guide, it will damage both the router bit and the guide.

►The routing pattern needs to be smaller than the desired routed edge as shown in both images to the right.

►The offset between the pattern and the final routed edge is ½ the difference between the template guide bushing diameter and the router bit diameter (shown in both images to the right).

For example, if you have a ½” diameter straight bit (as shown to the right) and a ¾”

diameter guide bushing, then your template

needs to be 1/8” smaller than the final cutout.

¾” - ½” = 1/8” 2

Advanced Routing Techniques

Multi-pass Cuts

Nearly all routing operations can be improved by making multiple passes. In some cases the routing operation would remove too much material to be completed effectively in a single pass. In other cases, the finished

cut is improved by making a shallow,

Multi-depth Ploughing

When ploughing out large volumes of material or making deep dados, make the cuts using successively deeper settings until the final depth is reached. The four positions of the depth stop turret are well suited for this type of operation. The 2mm offset post (see page 8) is used to make a final cleanup pass.

14 | OF 2200 EB Router |