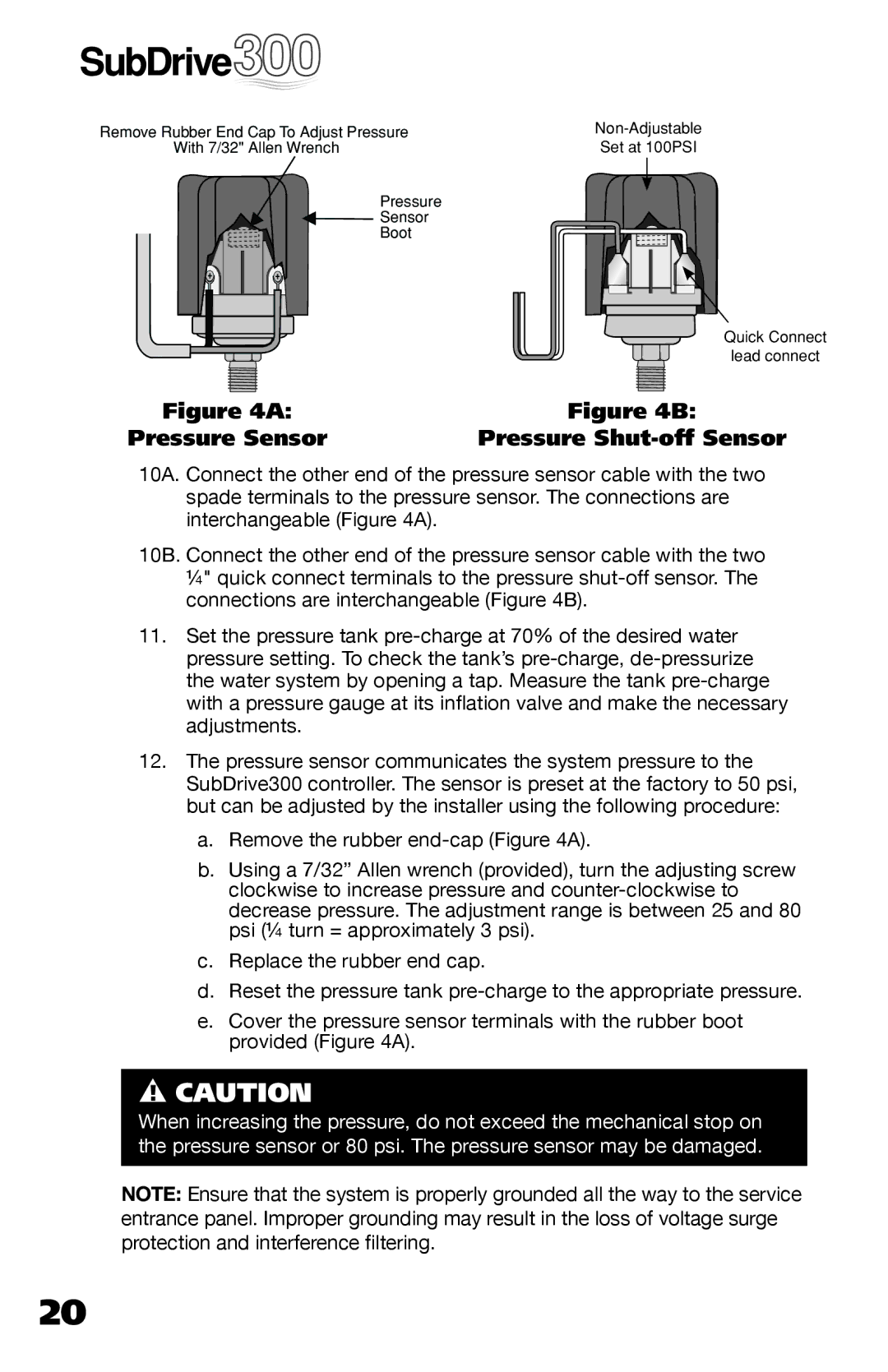

Remove Rubber End Cap To Adjust Pressure | |

With 7/32" Allen Wrench | Set at 100PSI |

Pressure

Sensor

Boot

| Quick Connect |

| lead connect |

Figure 4A: | Figure 4B: |

Pressure Sensor | Pressure |

10A. Connect the other end of the pressure sensor cable with the two spade terminals to the pressure sensor. The connections are interchangeable (Figure 4A).

10B. Connect the other end of the pressure sensor cable with the two ¼" quick connect terminals to the pressure

11.Set the pressure tank

12.The pressure sensor communicates the system pressure to the SubDrive300 controller. The sensor is preset at the factory to 50 psi, but can be adjusted by the installer using the following procedure:

a.Remove the rubber

b.Using a 7/32” Allen wrench (provided), turn the adjusting screw clockwise to increase pressure and

c.Replace the rubber end cap.

d.Reset the pressure tank

e.Cover the pressure sensor terminals with the rubber boot provided (Figure 4A).

▲! CAUTION

When increasing the pressure, do not exceed the mechanical stop on the pressure sensor or 80 psi. The pressure sensor may be damaged.

NOTE: Ensure that the system is properly grounded all the way to the service entrance panel. Improper grounding may result in the loss of voltage surge protection and interference filtering.

20