2.3 Monitor Unit

Two cables are terminated at the monitor unit: the signal cable from the processor unit (5 m or 10 m cable) and the power cable from the ship's mains. The signal cable comes with a connector pre- attached to it for connection to the monitor unit. Fabricate the power cable as below. Use cable

Note: Pass the AC line through a

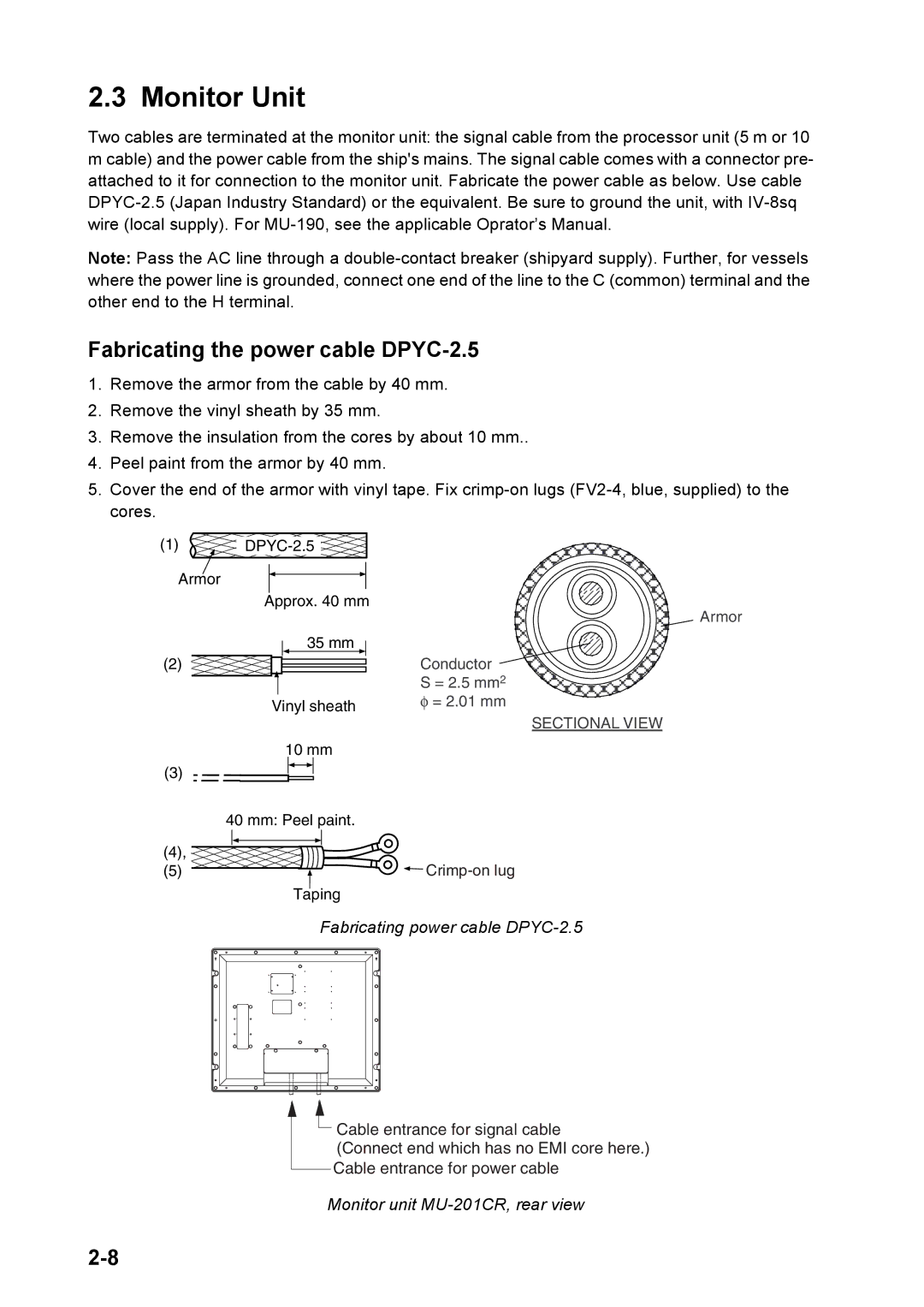

Fabricating the power cable DPYC-2.5

1.Remove the armor from the cable by 40 mm.

2.Remove the vinyl sheath by 35 mm.

3.Remove the insulation from the cores by about 10 mm..

4.Peel paint from the armor by 40 mm.

5.Cover the end of the armor with vinyl tape. Fix

(1) | |

Armor |

|

Approx. 40 mm

35 mm

(2)![]()

![]()

Vinyl sheath

10 mm

(3)

40 mm: Peel paint.

(4),

(5) ![]()

![]() Taping

Taping

Armor

Conductor S = 2.5 mm2 φ = 2.01 mm

SECTIONAL VIEW

![]()

![]()

Fabricating power cable DPYC-2.5

![]() Cable entrance for signal cable (Connect end which has no EMI core here.)

Cable entrance for signal cable (Connect end which has no EMI core here.)

Cable entrance for power cable

Monitor unit