1.5Correcting Magnetic Field Distortion (Deviation)

The magnetic field at the sensor around ship is subjects to change with the ship structure, engins, electronic equipment or any ferrous materials in the vicinity.

The

1.Do this procedure in a calm water.

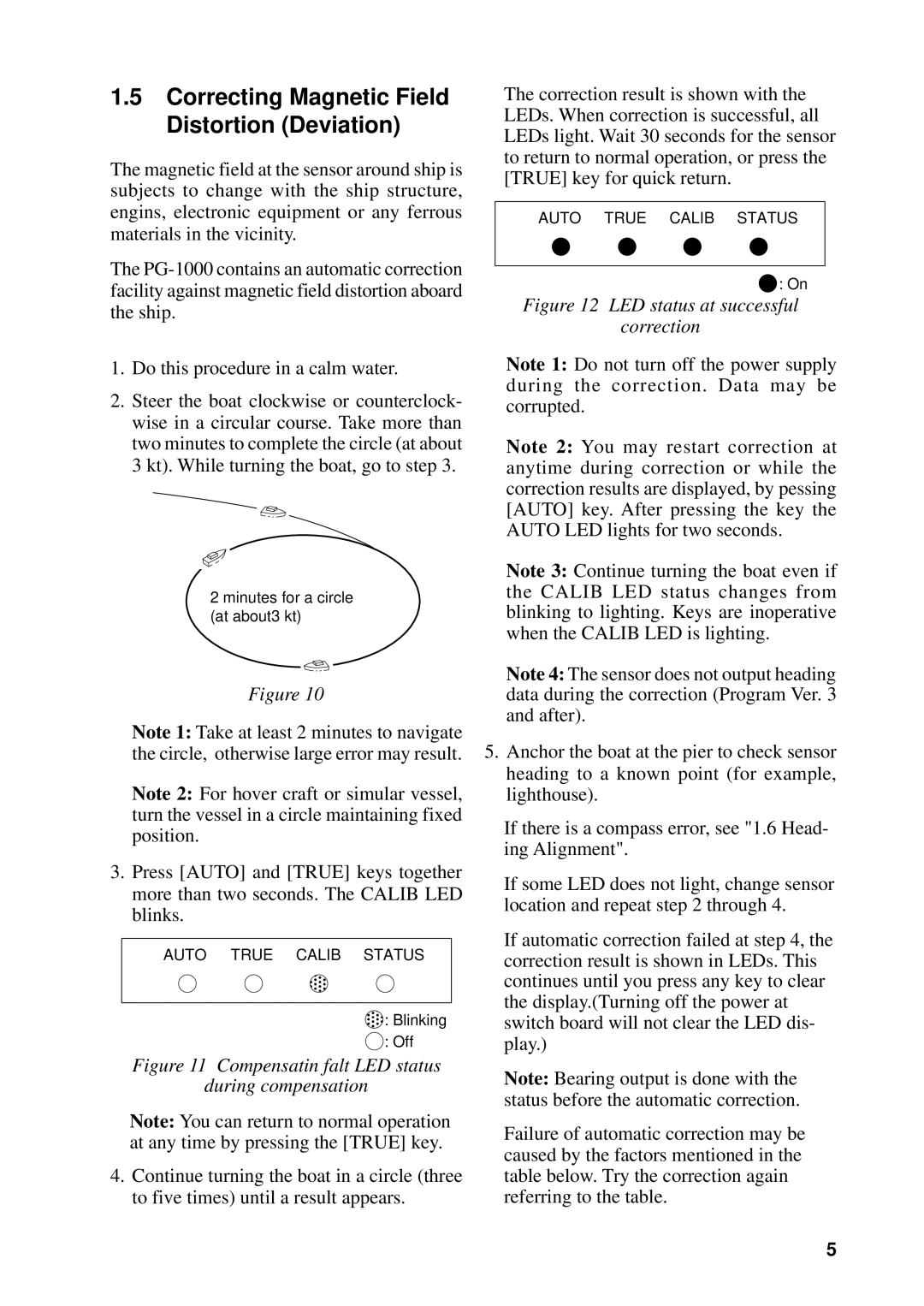

2.Steer the boat clockwise or counterclock- wise in a circular course. Take more than two minutes to complete the circle (at about 3 kt). While turning the boat, go to step 3.

The correction result is shown with the LEDs. When correction is successful, all LEDs light. Wait 30 seconds for the sensor to return to normal operation, or press the [TRUE] key for quick return.

AUTO TRUE CALIB STATUS

![]() : On

: On

Figure 12 LED status at successful

correction

Note 1: Do not turn off the power supply during the correction. Data may be corrupted.

Note 2: You may restart correction at anytime during correction or while the correction results are displayed, by pessing [AUTO] key. After pressing the key the AUTO LED lights for two seconds.

2 minutes for a circle (at about3 kt)

Figure 10

Note 1: Take at least 2 minutes to navigate the circle, otherwise large error may result.

Note 2: For hover craft or simular vessel, turn the vessel in a circle maintaining fixed position.

3.Press [AUTO] and [TRUE] keys together more than two seconds. The CALIB LED blinks

AUTO TRUE CALIB STATUS

: Blinking

: Off

Figure 11 Compensatin falt LED status

during compensation

Note: You can return to normal operation at any time by pressing the [TRUE] key.

4.Continue turning the boat in a circle (three to five times) until a result appears.

Note 3: Continue turning the boat even if the CALIB LED status changes from blinking to lighting. Keys are inoperative when the CALIB LED is lighting.

Note 4: The sensor does not output heading data during the correction (Program Ver. 3 and after).

5.Anchor the boat at the pier to check sensor heading to a known point (for example, lighthouse).

If there is a compass error, see "1.6 Head- ing Alignment".

If some LED does not light, change sensor location and repeat step 2 through 4.

If automatic correction failed at step 4, the correction result is shown in LEDs. This continues until you press any key to clear the display.(Turning off the power at switch board will not clear the LED dis- play.)

Note: Bearing output is done with the status before the automatic correction.

Failure of automatic correction may be caused by the factors mentioned in the table below. Try the correction again referring to the table.

5