PS Engineering

PAV80

Installation and Operator’s Manual

Appendix D- STC information and instructions for continuing airworthiness

8.1Instructions for FAA Form 337, PAV80s

The STC was developed using an Approved Model List (AML). One method of airworthiness approval is through an FAA Form 337, Major Repair and Alteration (Airframe, Powerplant, Propeller, or Appliance) In the case of the PAV80, you may use the following text as a guide.

This unit is installed in accordance with

Installed IFE System, PS Engineering PAV80, part number

Interface to existing aircraft radios in accordance with installation manual and in compliance with practices listed in

____________________. Power is supplied to the unit through a __A circuit breaker (type and part number),

and total electrical load does not exceed % of the electrical system capacity with the PAV80 added.

Aircraft equipment list, weights and balance amended. Compass compensation checked. A copy of the opera- tion instructions, contained in PS Engineering document 200-800-( ), revision ( ), dated ( ), is placed in the

aircraft records. All work accomplished listed on Work Order | . |

8.2Instructions for Continuing Airworthiness, PAV80s

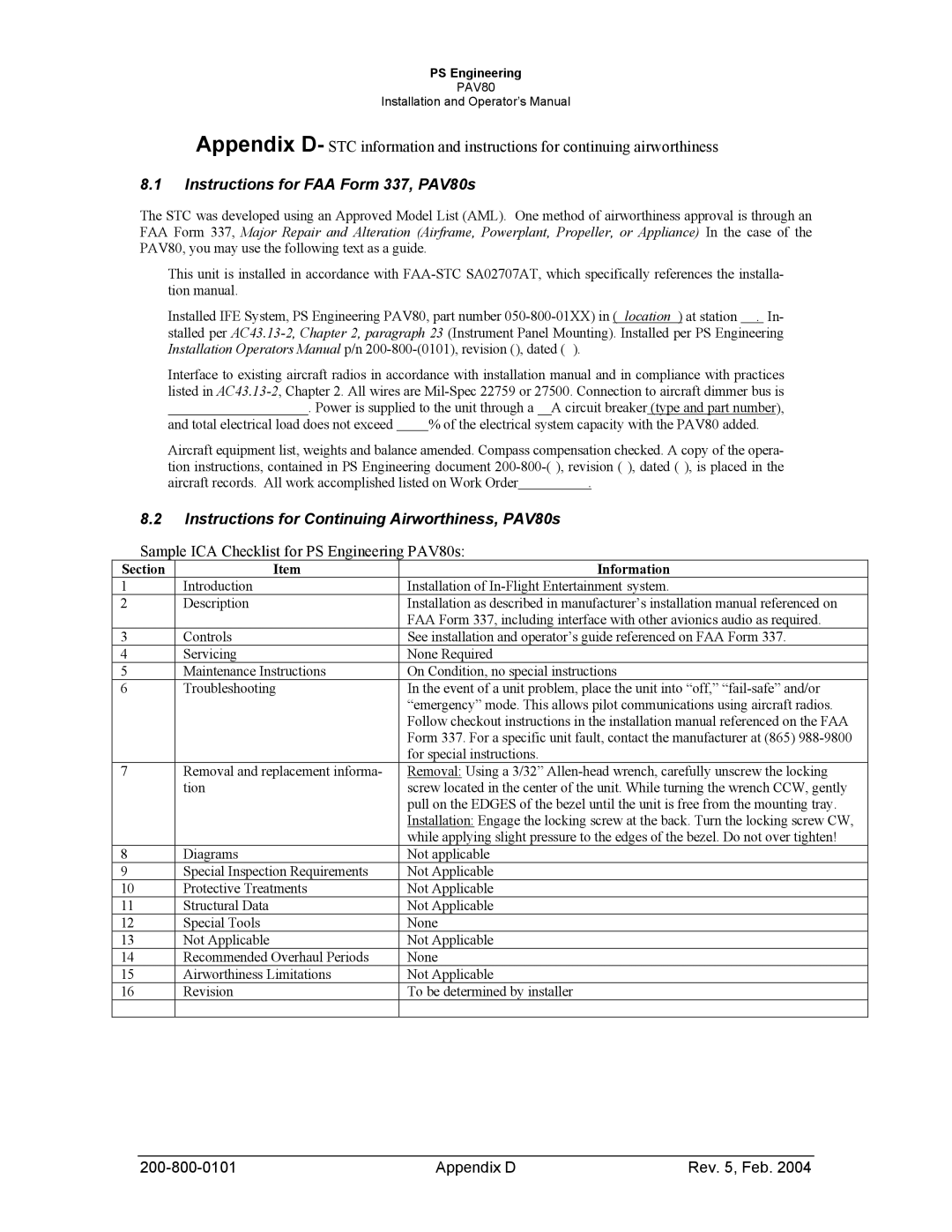

Sample ICA Checklist for PS Engineering PAV80s:

Section | Item | Information |

1 | Introduction | Installation of |

2 | Description | Installation as described in manufacturer’s installation manual referenced on |

|

| FAA Form 337, including interface with other avionics audio as required. |

3 | Controls | See installation and operator’s guide referenced on FAA Form 337. |

4 | Servicing | None Required |

5 | Maintenance Instructions | On Condition, no special instructions |

6 | Troubleshooting | In the event of a unit problem, place the unit into “off,” |

|

| “emergency” mode. This allows pilot communications using aircraft radios. |

|

| Follow checkout instructions in the installation manual referenced on the FAA |

|

| Form 337. For a specific unit fault, contact the manufacturer at (865) |

|

| for special instructions. |

7 | Removal and replacement informa- | Removal: Using a 3/32” |

| tion | screw located in the center of the unit. While turning the wrench CCW, gently |

|

| pull on the EDGES of the bezel until the unit is free from the mounting tray. |

|

| Installation: Engage the locking screw at the back. Turn the locking screw CW, |

|

| while applying slight pressure to the edges of the bezel. Do not over tighten! |

8 | Diagrams | Not applicable |

9 | Special Inspection Requirements | Not Applicable |

10 | Protective Treatments | Not Applicable |

11 | Structural Data | Not Applicable |

12 | Special Tools | None |

13 | Not Applicable | Not Applicable |

14 | Recommended Overhaul Periods | None |

15 | Airworthiness Limitations | Not Applicable |

16 | Revision | To be determined by installer |

|

|

|

Appendix D | Rev. 5, Feb. 2004 |