Spartan Operation and Maintenance Manual

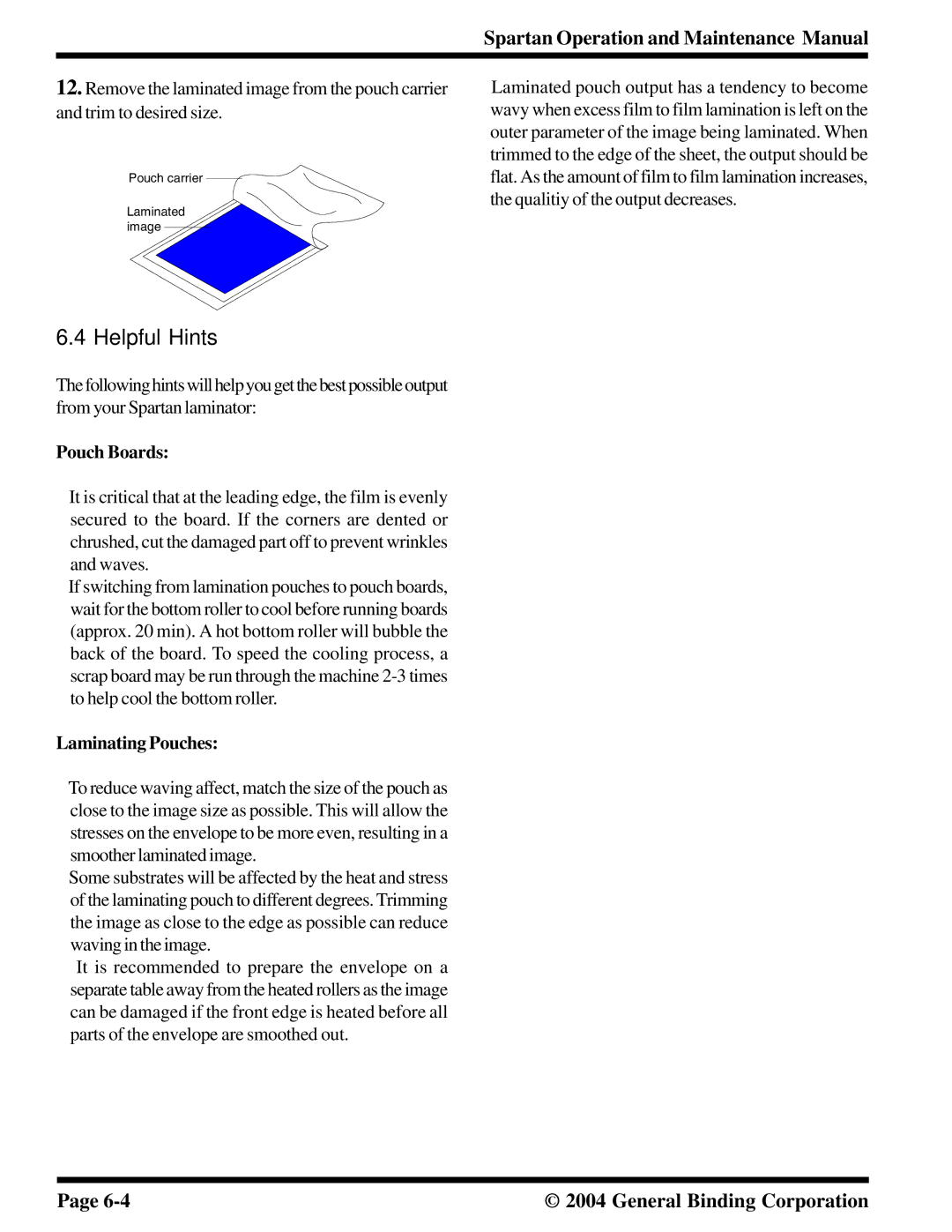

12.Remove the laminated image from the pouch carrier and trim to desired size.

Pouch carrier

Laminated image

•Laminated pouch output has a tendency to become wavy when excess film to film lamination is left on the outer parameter of the image being laminated. When trimmed to the edge of the sheet, the output should be flat. As the amount of film to film lamination increases, the qualitiy of the output decreases.

6.4 Helpful Hints

The following hints will help you get the best possible output from your Spartan laminator:

Pouch Boards:

•It is critical that at the leading edge, the film is evenly secured to the board. If the corners are dented or chrushed, cut the damaged part off to prevent wrinkles and waves.

•If switching from lamination pouches to pouch boards, wait for the bottom roller to cool before running boards (approx. 20 min). A hot bottom roller will bubble the back of the board. To speed the cooling process, a scrap board may be run through the machine

Laminating Pouches:

•To reduce waving affect, match the size of the pouch as close to the image size as possible. This will allow the stresses on the envelope to be more even, resulting in a smoother laminated image.

•Some substrates will be affected by the heat and stress of the laminating pouch to different degrees. Trimming the image as close to the edge as possible can reduce waving in the image.

•It is recommended to prepare the envelope on a separate table away from the heated rollers as the image can be damaged if the front edge is heated before all parts of the envelope are smoothed out.

Page | © 2004 General Binding Corporation |