ge.com

Breaking a Salt Bridge

Sometimes, a hard crust or salt bridge forms in the salt storage area. It is usually caused by high humidity or the wrong kind of salt. When the salt bridges, an empty space forms between the water and salt. Then salt will not dissolve in the water to make brine.

If the brine tank is full of salt, it is hard to tell

if you have a salt bridge. Salt is loose on top, but the bridge is under it. The following is the best way to check for a salt bridge.

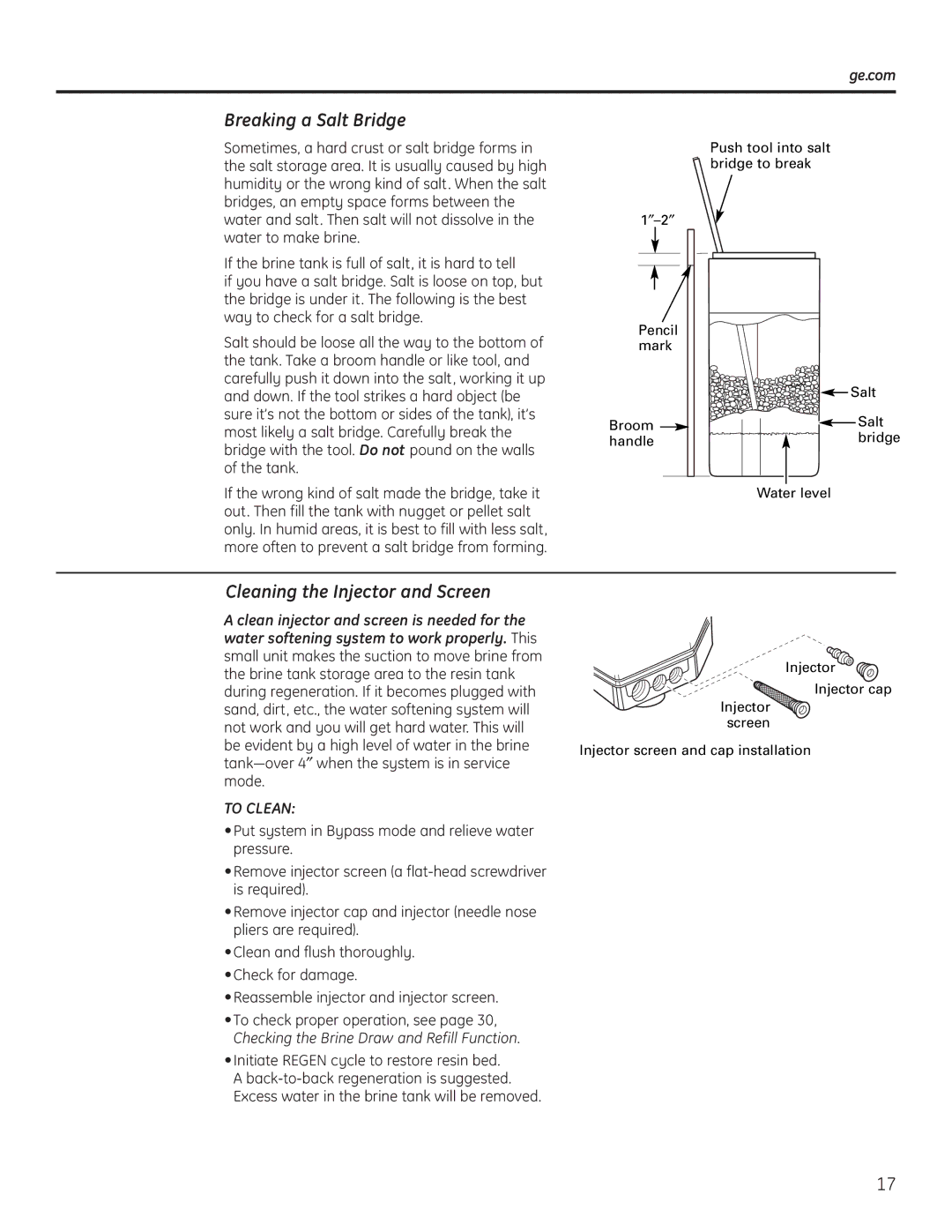

Salt should be loose all the way to the bottom of the tank. Take a broom handle or like tool, and carefully push it down into the salt, working it up and down. If the tool strikes a hard object (be sure it’s not the bottom or sides of the tank), it’s most likely a salt bridge. Carefully break the bridge with the tool. Do not pound on the walls of the tank.

Push tool into salt bridge to break

Pencil |

|

mark |

|

| Salt |

Broom | Salt |

handle | bridge |

If the wrong kind of salt made the bridge, take it | Water level |

out. Then fill the tank with nugget or pellet salt |

|

only. In humid areas, it is best to fill with less salt, |

|

more often to prevent a salt bridge from forming. |

|

Cleaning the Injector and Screen

A clean injector and screen is needed for the water softening system to work properly. This small unit makes the suction to move brine from the brine tank storage area to the resin tank during regeneration. If it becomes plugged with sand, dirt, etc., the water softening system will not work and you will get hard water. This will be evident by a high level of water in the brine

TO CLEAN:

•Put system in Bypass mode and relieve water pressure.

•Remove injector screen (a

•Remove injector cap and injector (needle nose pliers are required).

•Clean and flush thoroughly.

•Check for damage.

•Reassemble injector and injector screen.

•To check proper operation, see page 30, Checking the Brine Draw and Refill Function.

•Initiate REGEN cycle to restore resin bed. A

Injector

Injector cap

Injector screen

Injector screen and cap installation

17