Section 2 – Operation

Residential Portable Generator System

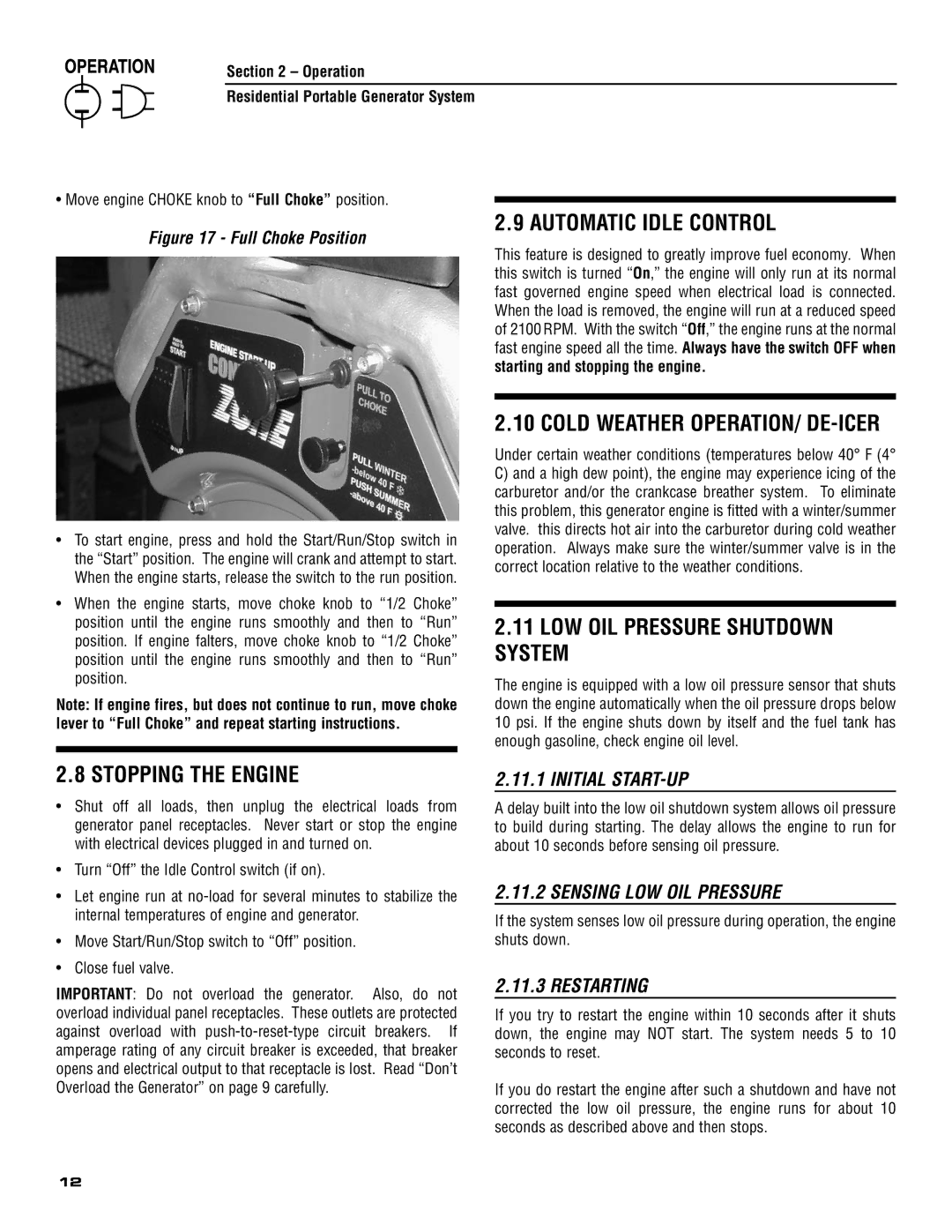

• Move engine CHOKE knob to “Full Choke” position.

2.9 AUTOMATIC IDLE CONTROL

Figure 17 - Full Choke Position

•To start engine, press and hold the Start/Run/Stop switch in the “Start” position. The engine will crank and attempt to start. When the engine starts, release the switch to the run position.

•When the engine starts, move choke knob to “1/2 Choke” position until the engine runs smoothly and then to “Run” position. If engine falters, move choke knob to “1/2 Choke” position until the engine runs smoothly and then to “Run” position.

Note: If engine fires, but does not continue to run, move choke lever to “Full Choke” and repeat starting instructions.

This feature is designed to greatly improve fuel economy. When this switch is turned “On,” the engine will only run at its normal fast governed engine speed when electrical load is connected. When the load is removed, the engine will run at a reduced speed of 2100 RPM. With the switch “Off,” the engine runs at the normal fast engine speed all the time. Always have the switch OFF when starting and stopping the engine.

2.10 COLD WEATHER OPERATION/ DE-ICER

Under certain weather conditions (temperatures below 40° F (4°

C)and a high dew point), the engine may experience icing of the carburetor and/or the crankcase breather system. To eliminate this problem, this generator engine is fitted with a winter/summer valve. this directs hot air into the carburetor during cold weather operation. Always make sure the winter/summer valve is in the correct location relative to the weather conditions.

2.11LOW OIL PRESSURE SHUTDOWN SYSTEM

The engine is equipped with a low oil pressure sensor that shuts down the engine automatically when the oil pressure drops below 10 psi. If the engine shuts down by itself and the fuel tank has enough gasoline, check engine oil level.

2.8 STOPPING THE ENGINE

•Shut off all loads, then unplug the electrical loads from generator panel receptacles. Never start or stop the engine with electrical devices plugged in and turned on.

•Turn “Off” the Idle Control switch (if on).

•Let engine run at

•Move Start/Run/Stop switch to “Off” position.

•Close fuel valve.

IMPORTANT: Do not overload the generator. Also, do not overload individual panel receptacles. These outlets are protected against overload with

2.11.1 INITIAL START-UP

A delay built into the low oil shutdown system allows oil pressure to build during starting. The delay allows the engine to run for about 10 seconds before sensing oil pressure.

2.11.2 SENSING LOW OIL PRESSURE

If the system senses low oil pressure during operation, the engine shuts down.

2.11.3 RESTARTING

If you try to restart the engine within 10 seconds after it shuts down, the engine may NOT start. The system needs 5 to 10 seconds to reset.

If you do restart the engine after such a shutdown and have not corrected the low oil pressure, the engine runs for about 10 seconds as described above and then stops.

12