Chapter 6: Maintaining Your Filtered Enclosure

Formaldehyde only

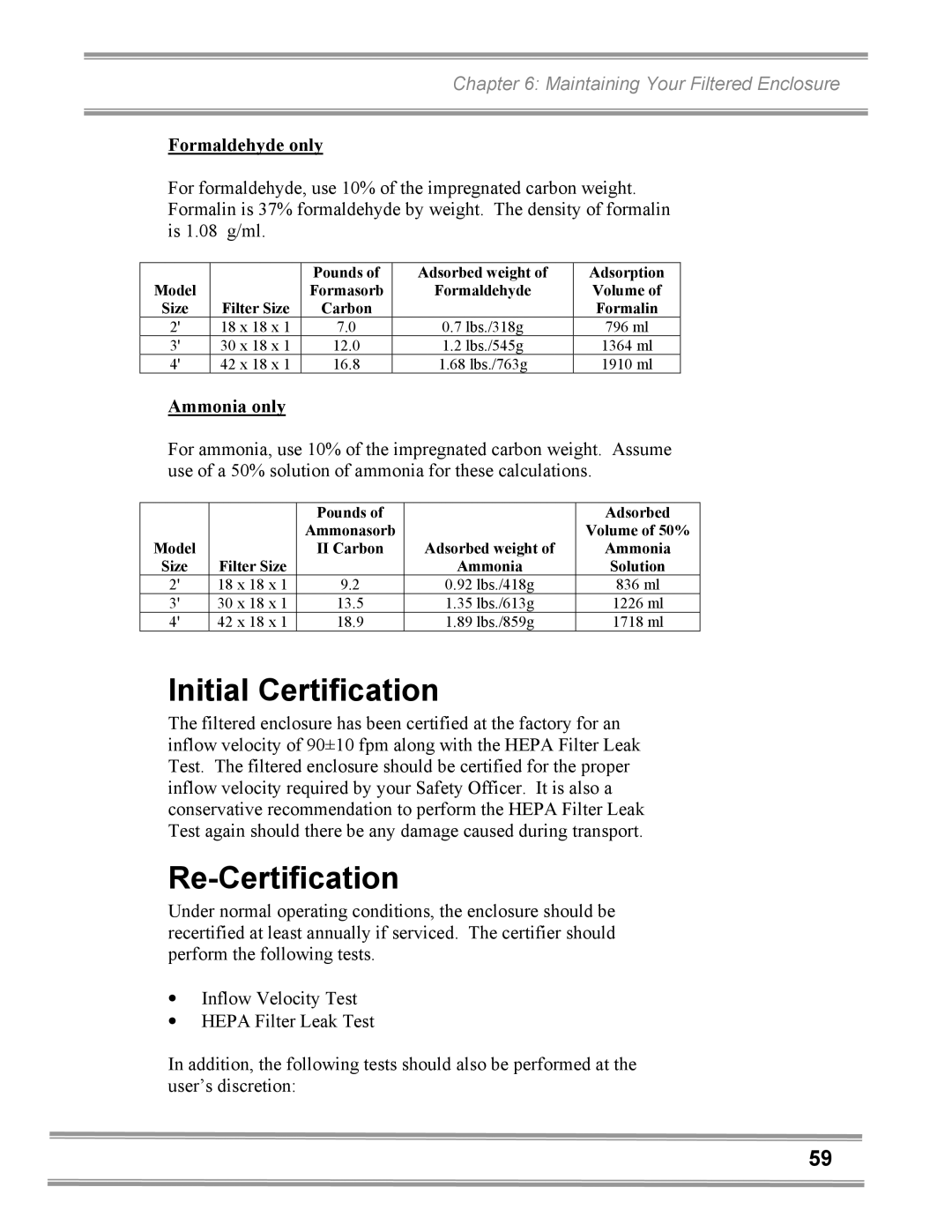

For formaldehyde, use 10% of the impregnated carbon weight. Formalin is 37% formaldehyde by weight. The density of formalin is 1.08 g/ml.

|

| Pounds of | Adsorbed weight of | Adsorption |

Model |

| Formasorb | Formaldehyde | Volume of |

Size | Filter Size | Carbon |

| Formalin |

2' | 18 x 18 x 1 | 7.0 | 0.7 lbs./318g | 796 ml |

3' | 30 x 18 x 1 | 12.0 | 1.2 lbs./545g | 1364 ml |

4' | 42 x 18 x 1 | 16.8 | 1.68 lbs./763g | 1910 ml |

Ammonia only

For ammonia, use 10% of the impregnated carbon weight. Assume use of a 50% solution of ammonia for these calculations.

|

| Pounds of |

| Adsorbed |

|

| Ammonasorb |

| Volume of 50% |

Model |

| II Carbon | Adsorbed weight of | Ammonia |

Size | Filter Size |

| Ammonia | Solution |

2' | 18 x 18 x 1 | 9.2 | 0.92 lbs./418g | 836 ml |

3' | 30 x 18 x 1 | 13.5 | 1.35 lbs./613g | 1226 ml |

4' | 42 x 18 x 1 | 18.9 | 1.89 lbs./859g | 1718 ml |

Initial Certification

The filtered enclosure has been certified at the factory for an inflow velocity of 90±10 fpm along with the HEPA Filter Leak Test. The filtered enclosure should be certified for the proper inflow velocity required by your Safety Officer. It is also a conservative recommendation to perform the HEPA Filter Leak Test again should there be any damage caused during transport.

Re-Certification

Under normal operating conditions, the enclosure should be recertified at least annually if serviced. The certifier should perform the following tests.

•Inflow Velocity Test

•HEPA Filter Leak Test

In addition, the following tests should also be performed at the user’s discretion:

59