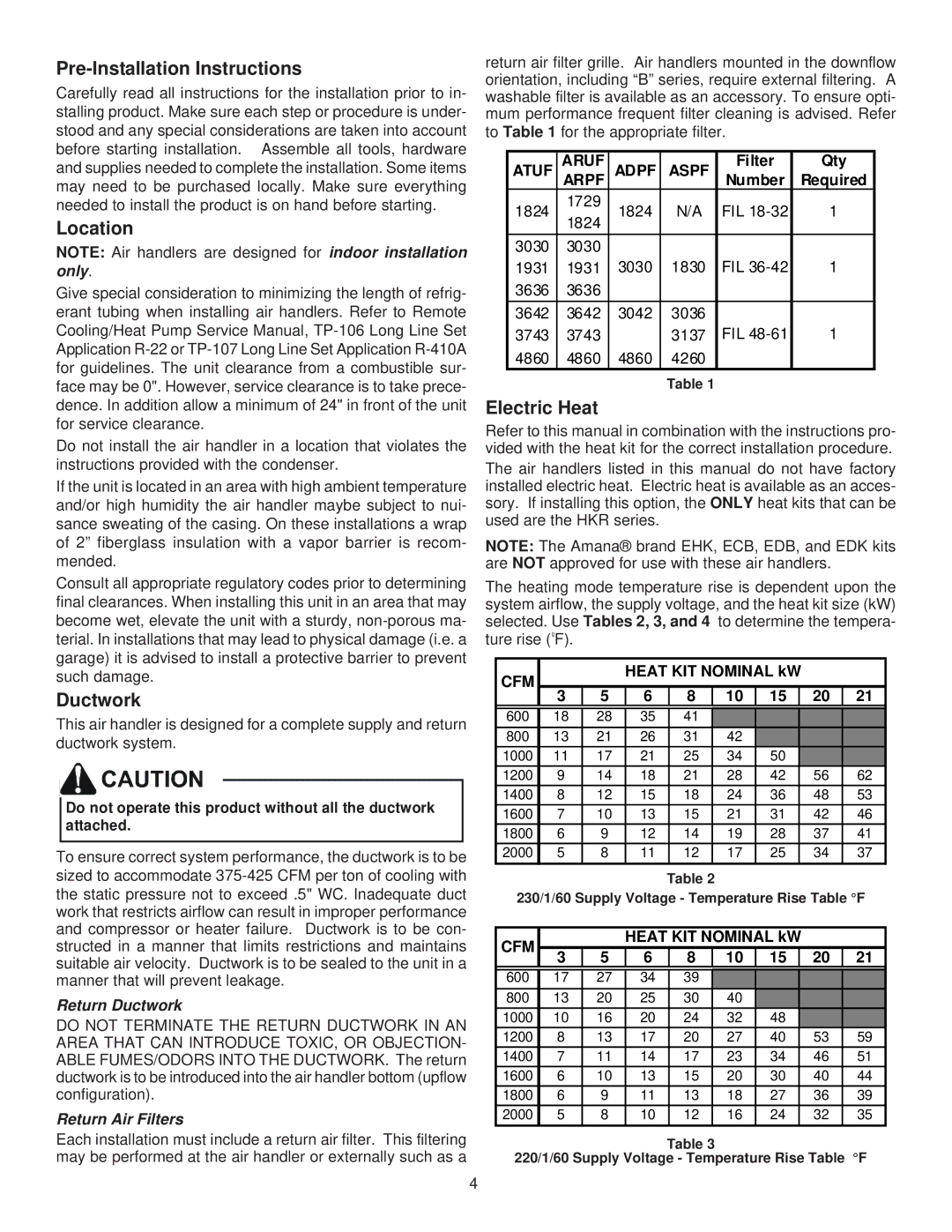

ATUF, ADPF, ASPF, ARUF specifications

Goodman Manufacturing is synonymous with quality and reliability in the HVAC industry, offering a wide range of air handling units, including the ARUF, ASPF, ADPF, and ATUF series. These products showcase advanced technologies while providing cost-effective solutions for residential and commercial applications.The ARUF series is designed specifically for reliable indoor air management. These air handlers are known for their high-efficiency performance and compact design, making them suitable for tight spaces. They feature an insulated cabinet that minimizes noise and energy loss, ensuring a quieter operation and increased comfort. The ARUF units also have a multi-speed blower motor, which provides improved airflow and better temperature control, enhancing overall system efficiency.

The ASPF series stands out with its variable-speed motor technology. This innovation allows for precise airflow adjustments, adapting seamlessly to changing thermal loads within the space. Such adaptability not only improves comfort levels but also leads to energy savings by optimizing performance during varying usage periods. Additionally, the ASPF air handlers are designed for easy installation, incorporating lightweight components and a versatile design that accommodates different configurations and applications.

Meanwhile, the ADPF series is highly regarded for its durability and performance in moisture-rich environments. Engineered with a robust housing, the ADPF units offer increased corrosion resistance, making them ideal for locations susceptible to humidity. The units come equipped with enhanced filtration capabilities, ensuring improved indoor air quality by capturing dust, pet dander, and other allergens effectively.

Lastly, the ATUF series combines advanced technology with user-friendly features. These units feature a high-efficiency air filter and a low-profile design, perfect for a variety of applications. The ATUF air handlers come equipped with integrated control systems that allow users to easily adjust settings and monitor performance, ensuring optimal operation over time.

In summary, Goodman Manufacturing's ARUF, ASPF, ADPF, and ATUF air handling units showcase cutting-edge technologies, robust construction, and energy-efficient designs. Each series offers unique features tailored to meet the diverse needs of customers, ensuring enhanced comfort and cost savings in residential and commercial environments. With a commitment to quality and innovation, Goodman continues to be a leader in the HVAC market.