Warnings

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever you see this symbol.

I

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief Procedure when you stop pumping and before cleaning, checking or servicing the equipment.

1.Stop lube pump.

2.If installed, close oil supply valve located upstream from pump.

3.If installed, open drain valve located downstream from the pump.

4.Slowly crack open fluid line fittings to relieve pres- sure.

Installing the Pump

Grounding

The equipment must be grounded to reduce the risk of static sparking. Static sparking can cause fumes to ignite or explode. Grounding provides an escape wire for the electric current.

Ensure the reservoir is properly grounded as the pump is grounded through the mounting screws.

Mounting Pump

NOTE:

•Ensure box and lube system are sized appropriately for the selected pressure.

•Ensure an appropriate pressure relief device, suit- able for your application, is installed in the system.

•Inspect your box lubricator and replace any dam- naged or worn components.

| d |

e | b |

f | c |

a

FIG. 1

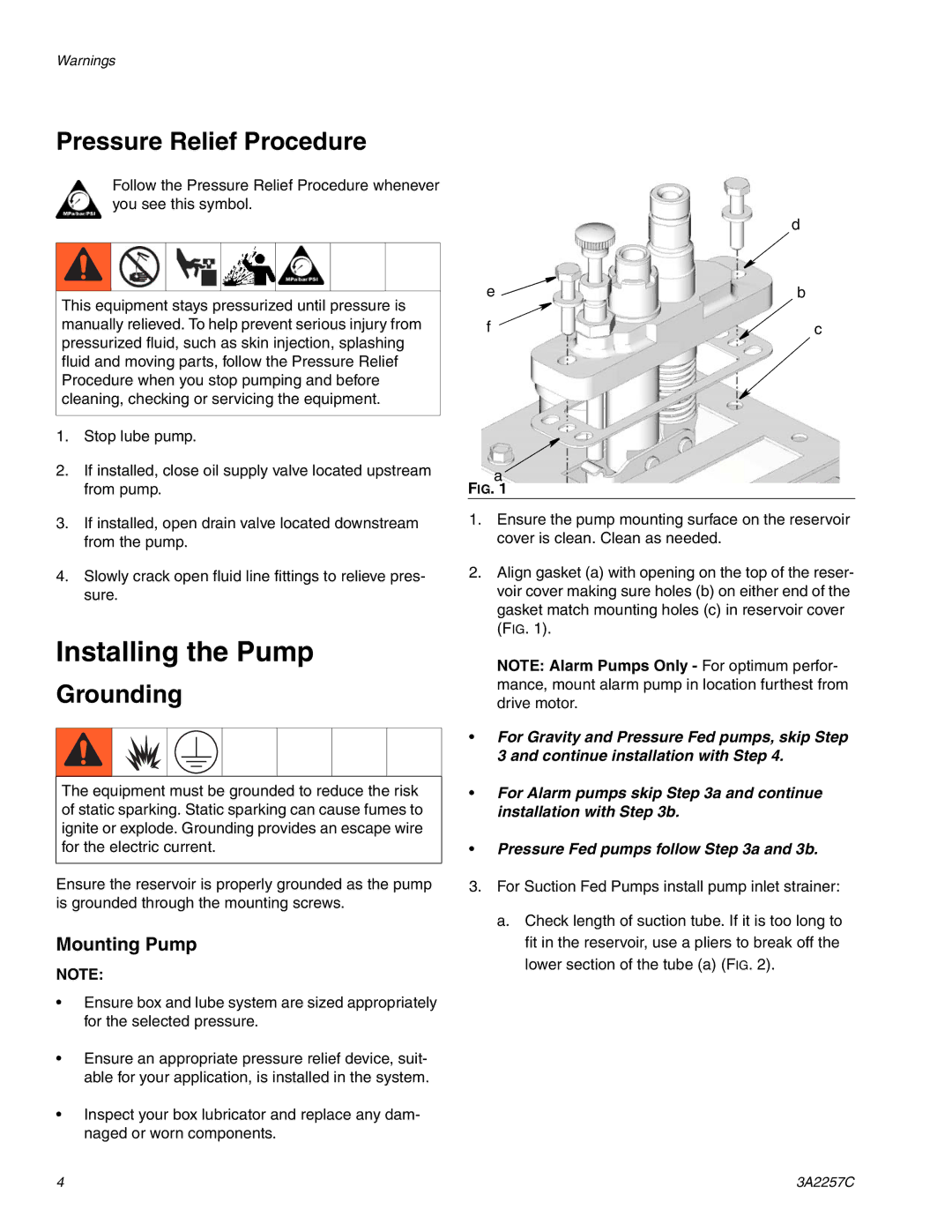

1.Ensure the pump mounting surface on the reservoir cover is clean. Clean as needed.

2.Align gasket (a) with opening on the top of the reser- voir cover making sure holes (b) on either end of the gasket match mounting holes (c) in reservoir cover (FIG. 1).

NOTE: Alarm Pumps Only - For optimum perfor- mance, mount alarm pump in location furthest from drive motor.

•For Gravity and Pressure Fed pumps, skip Step 3 and continue installation with Step 4.

•For Alarm pumps skip Step 3a and continue installation with Step 3b.

•Pressure Fed pumps follow Step 3a and 3b.

3.For Suction Fed Pumps install pump inlet strainer:

a.Check length of suction tube. If it is too long to fit in the reservoir, use a pliers to break off the lower section of the tube (a) (FIG. 2).

4 | 3A2257C |