Repair

Before you start

•Have all the necessary repair parts on hand.

•Clean all parts with a compatible solvent. Inspect parts for wear or damage and replace as needed.

•Flush the pump, if possible. Stop the pump at the bottom of its stroke. Follow Pressure Relief Procedure on page 13 before repairing any part of the system.

•Disconnect the air and the fluid hoses and the grounding wire. Remove the pump from its mounting and clamp it in a vise.

Required Tools

•Pliers

•Set of socket wrenches

•Set of adjustable wrenches

•Insert Tool 24B917

Repair

Air Motor Disassembly

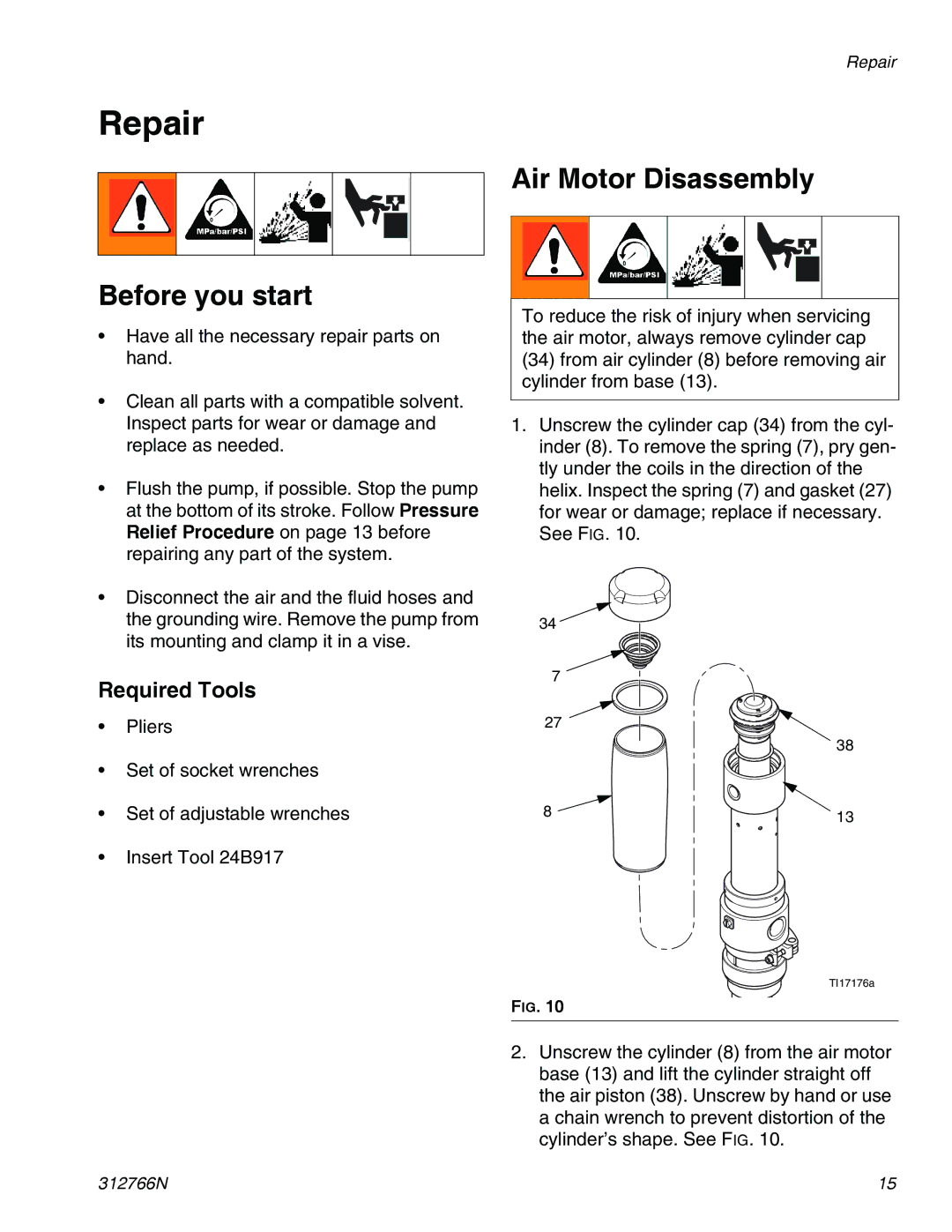

To reduce the risk of injury when servicing the air motor, always remove cylinder cap

(34)from air cylinder (8) before removing air cylinder from base (13).

1.Unscrew the cylinder cap (34) from the cyl- inder (8). To remove the spring (7), pry gen- tly under the coils in the direction of the helix. Inspect the spring (7) and gasket (27) for wear or damage; replace if necessary. See FIG. 10.

34 |

|

7 |

|

27 |

|

| 38 |

8 | 13 |

|

TI17176a

FIG. 10

2.Unscrew the cylinder (8) from the air motor base (13) and lift the cylinder straight off the air piston (38). Unscrew by hand or use a chain wrench to prevent distortion of the cylinder’s shape. See FIG. 10.

312766N | 15 |