Setup

NOTICE

DO NOT USE MATERIALS THAT CURE RAPIDLY! Materials with a fast curing time could plug the pump, hose, gun, or applicator.

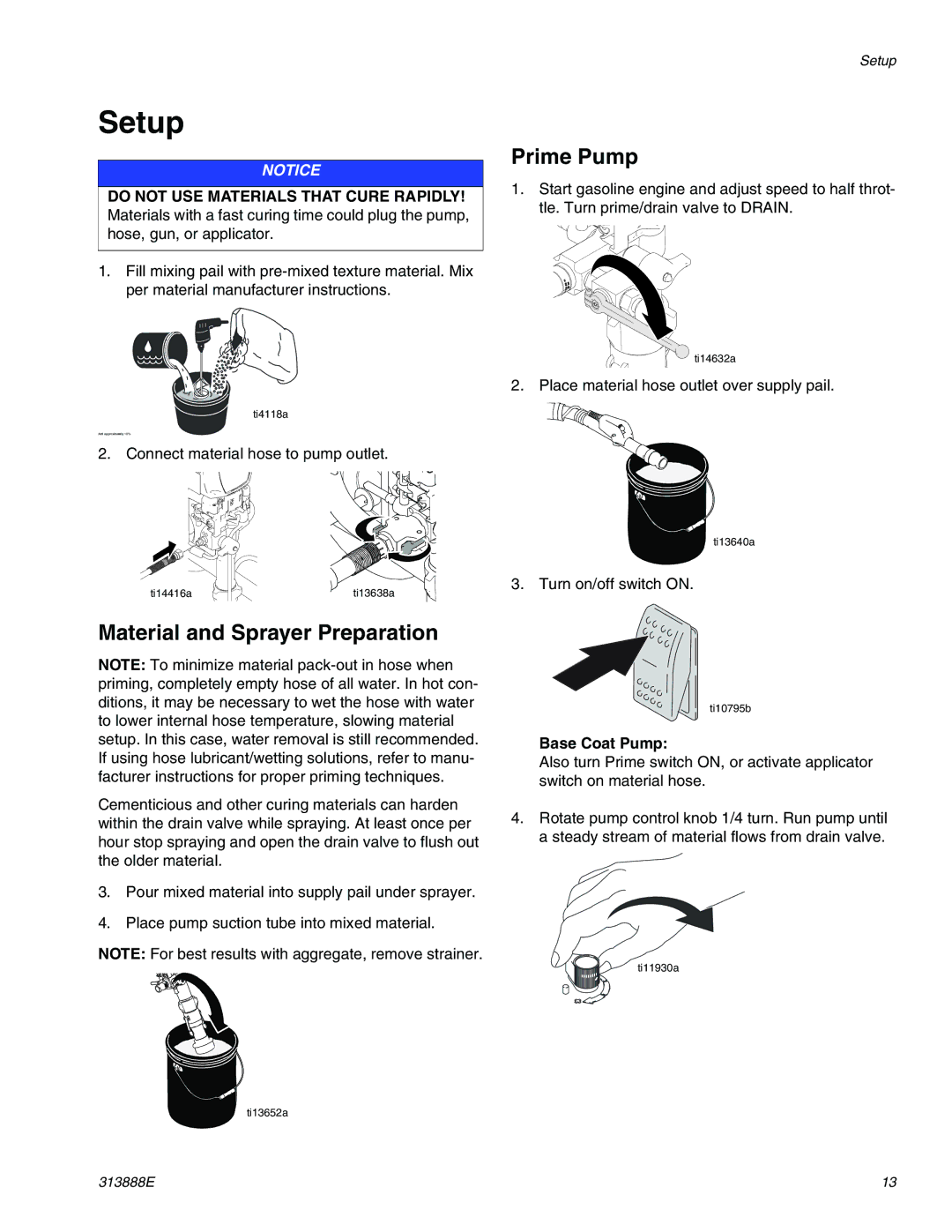

1.Fill mixing pail with

ti4118a

Add approximately 10% water to texture mix or per material manufacturer instructions. Mix thoroughly.

2. Connect material hose to pump outlet.

ti14416a | ti13638a |

Setup

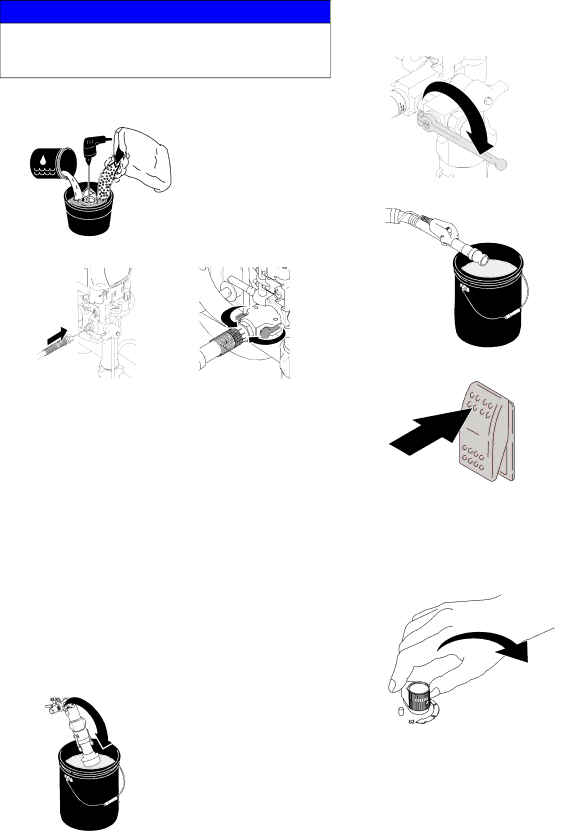

Prime Pump

1.Start gasoline engine and adjust speed to half throt- tle. Turn prime/drain valve to DRAIN.

ti14632a

2. Place material hose outlet over supply pail.

ti13640a

3. Turn on/off switch ON.

Material and Sprayer Preparation

NOTE: To minimize material

Cementicious and other curing materials can harden within the drain valve while spraying. At least once per hour stop spraying and open the drain valve to flush out the older material.

3.Pour mixed material into supply pail under sprayer.

4.Place pump suction tube into mixed material.

NOTE: For best results with aggregate, remove strainer.

ti13652a

ti10795b

Base Coat Pump:

Also turn Prime switch ON, or activate applicator switch on material hose.

4.Rotate pump control knob 1/4 turn. Run pump until a steady stream of material flows from drain valve.

ti11930a

313888E | 13 |