Grounding

Grounding

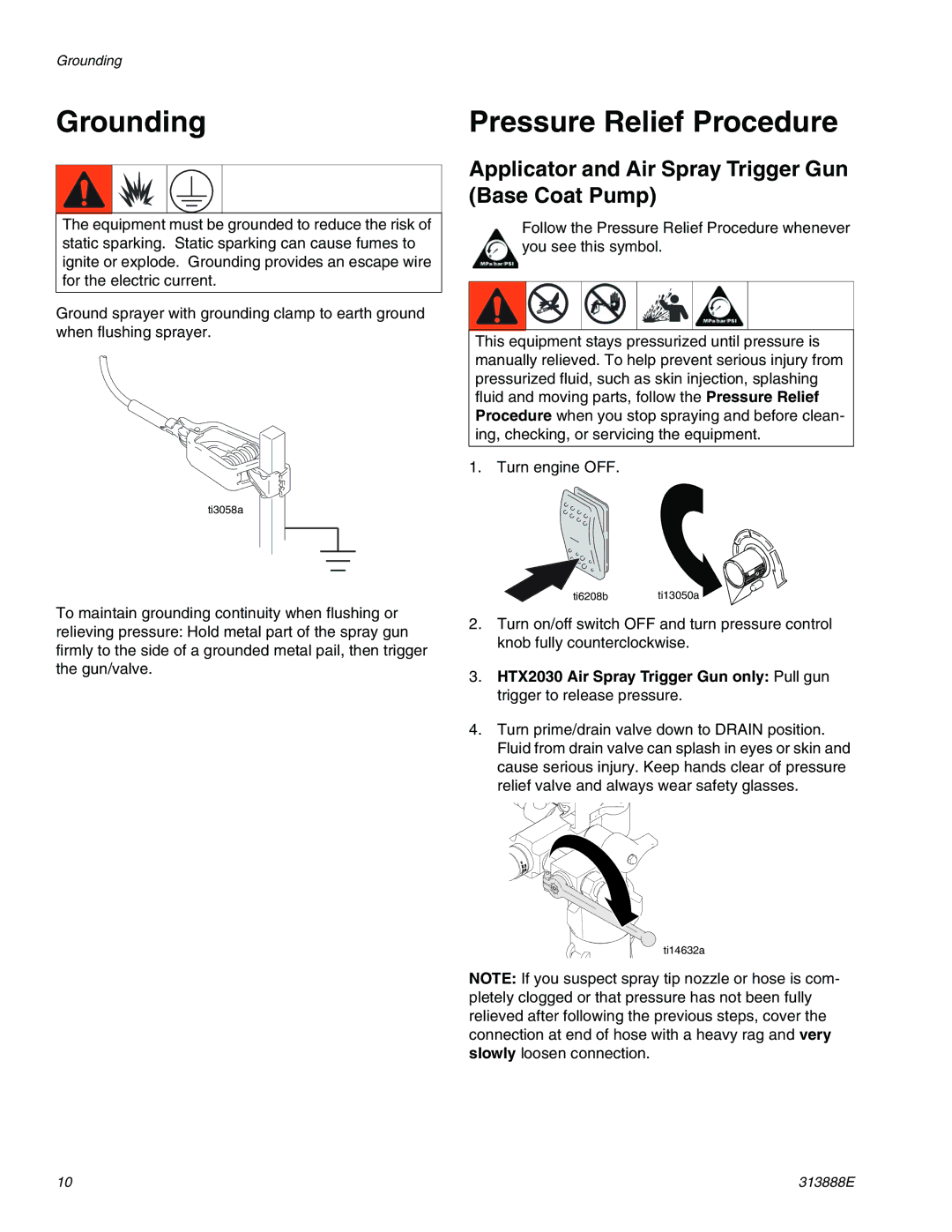

The equipment must be grounded to reduce the risk of static sparking. Static sparking can cause fumes to ignite or explode. Grounding provides an escape wire for the electric current.

Ground sprayer with grounding clamp to earth ground when flushing sprayer.

ti3058a

To maintain grounding continuity when flushing or relieving pressure: Hold metal part of the spray gun firmly to the side of a grounded metal pail, then trigger the gun/valve.

Pressure Relief Procedure

Applicator and Air Spray Trigger Gun (Base Coat Pump)

Follow the Pressure Relief Procedure whenever you see this symbol.

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief Procedure when you stop spraying and before clean- ing, checking, or servicing the equipment.

1. Turn engine OFF.

ti6208b ti13050a

2.Turn on/off switch OFF and turn pressure control knob fully counterclockwise.

3.HTX2030 Air Spray Trigger Gun only: Pull gun trigger to release pressure.

4.Turn prime/drain valve down to DRAIN position. Fluid from drain valve can splash in eyes or skin and cause serious injury. Keep hands clear of pressure relief valve and always wear safety glasses.

ti14632a

NOTE: If you suspect spray tip nozzle or hose is com- pletely clogged or that pressure has not been fully relieved after following the previous steps, cover the connection at end of hose with a heavy rag and very slowly loosen connection.

10 | 313888E |