Operation

Operation

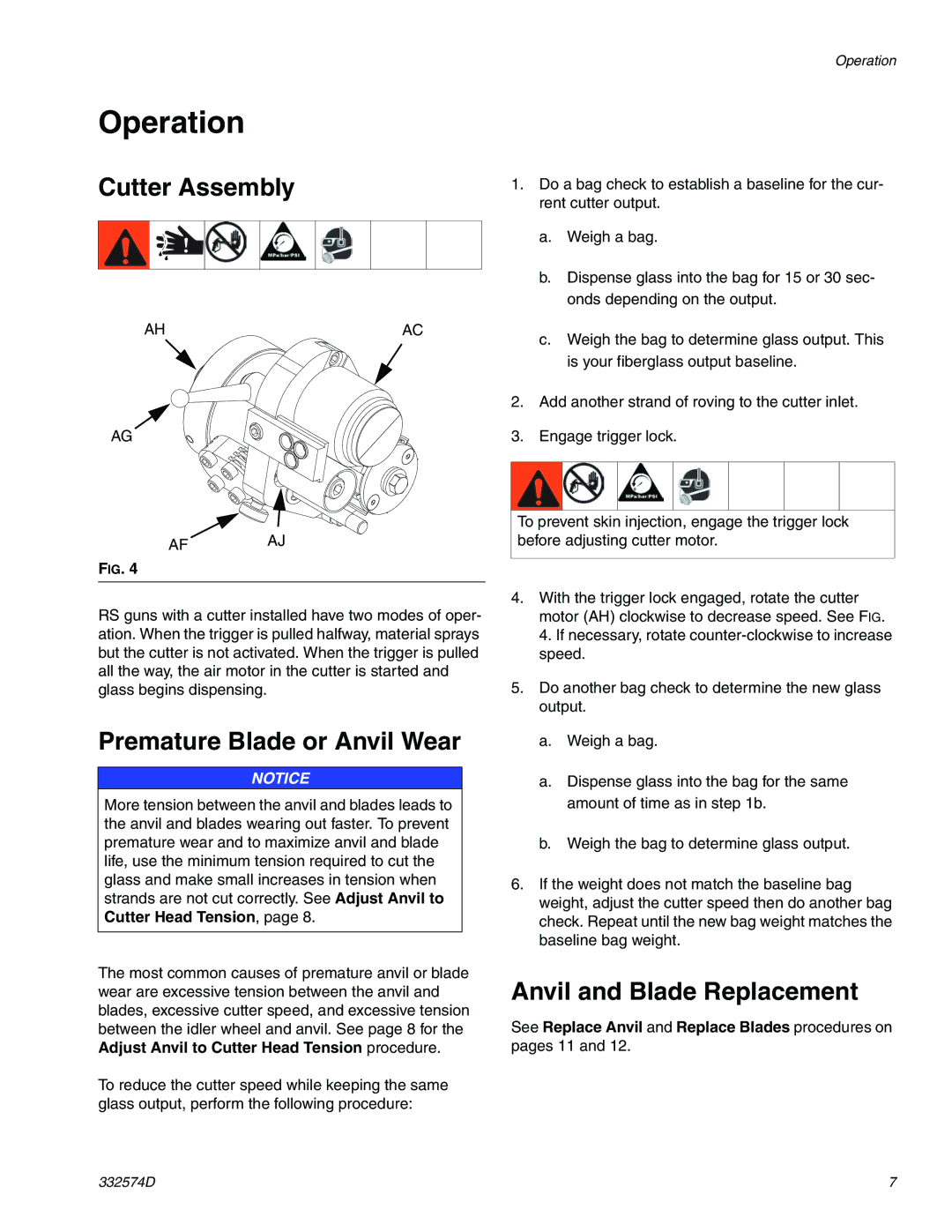

Cutter Assembly

AH | AC |

AG

AF AJ

FIG. 4

RS guns with a cutter installed have two modes of oper- ation. When the trigger is pulled halfway, material sprays but the cutter is not activated. When the trigger is pulled all the way, the air motor in the cutter is started and glass begins dispensing.

Premature Blade or Anvil Wear

NOTICE

More tension between the anvil and blades leads to the anvil and blades wearing out faster. To prevent premature wear and to maximize anvil and blade life, use the minimum tension required to cut the glass and make small increases in tension when strands are not cut correctly. See Adjust Anvil to Cutter Head Tension, page 8.

The most common causes of premature anvil or blade wear are excessive tension between the anvil and blades, excessive cutter speed, and excessive tension between the idler wheel and anvil. See page 8 for the Adjust Anvil to Cutter Head Tension procedure.

To reduce the cutter speed while keeping the same glass output, perform the following procedure:

1.Do a bag check to establish a baseline for the cur- rent cutter output.

a.Weigh a bag.

b.Dispense glass into the bag for 15 or 30 sec- onds depending on the output.

c.Weigh the bag to determine glass output. This is your fiberglass output baseline.

2.Add another strand of roving to the cutter inlet.

3.Engage trigger lock.

To prevent skin injection, engage the trigger lock before adjusting cutter motor.

4.With the trigger lock engaged, rotate the cutter motor (AH) clockwise to decrease speed. See FIG. 4. If necessary, rotate

5.Do another bag check to determine the new glass output.

a. Weigh a bag.

a.Dispense glass into the bag for the same amount of time as in step 1b.

b.Weigh the bag to determine glass output.

6.If the weight does not match the baseline bag weight, adjust the cutter speed then do another bag check. Repeat until the new bag weight matches the baseline bag weight.

Anvil and Blade Replacement

See Replace Anvil and Replace Blades procedures on pages 11 and 12.

332574D | 7 |