Maintenance

Maintenance

Tools Required

The following tools are required to perform regular main- tenance on the gun.

•7/16 in. wrench

•1/2 in. wrench

•9/16 in. wrench

•5/8 in. wrench

•11/16 in. wrench

•3/4 in. wrench

•13/16 in. wrench

•5/64 in. allen key

•3/32 in. allen key (supplied)

•9/64 in. allen key (supplied)

•3/16 in. allen key (supplied with cutter assembly)

•1/2 in. deep well socket

•9/32 in. socket

•7/32 in. deep well socket

•5/16 in. nut drive (supplied)

Task | Schedule |

|

|

Add Oil to Air Motor, | |

page 10 | use |

|

|

Replace Anvil, page 11 | When surface is badly |

| scored or does not cut |

|

|

Replace Cutter Head, | When glass roving is no |

page 12 | longer cut cleanly (verify |

| proper tension first) |

|

|

Air Motor Oiling

1.Perform Pressure Relief Procedure found within the RS Gun and Cutter,

2.Engage trigger lock.

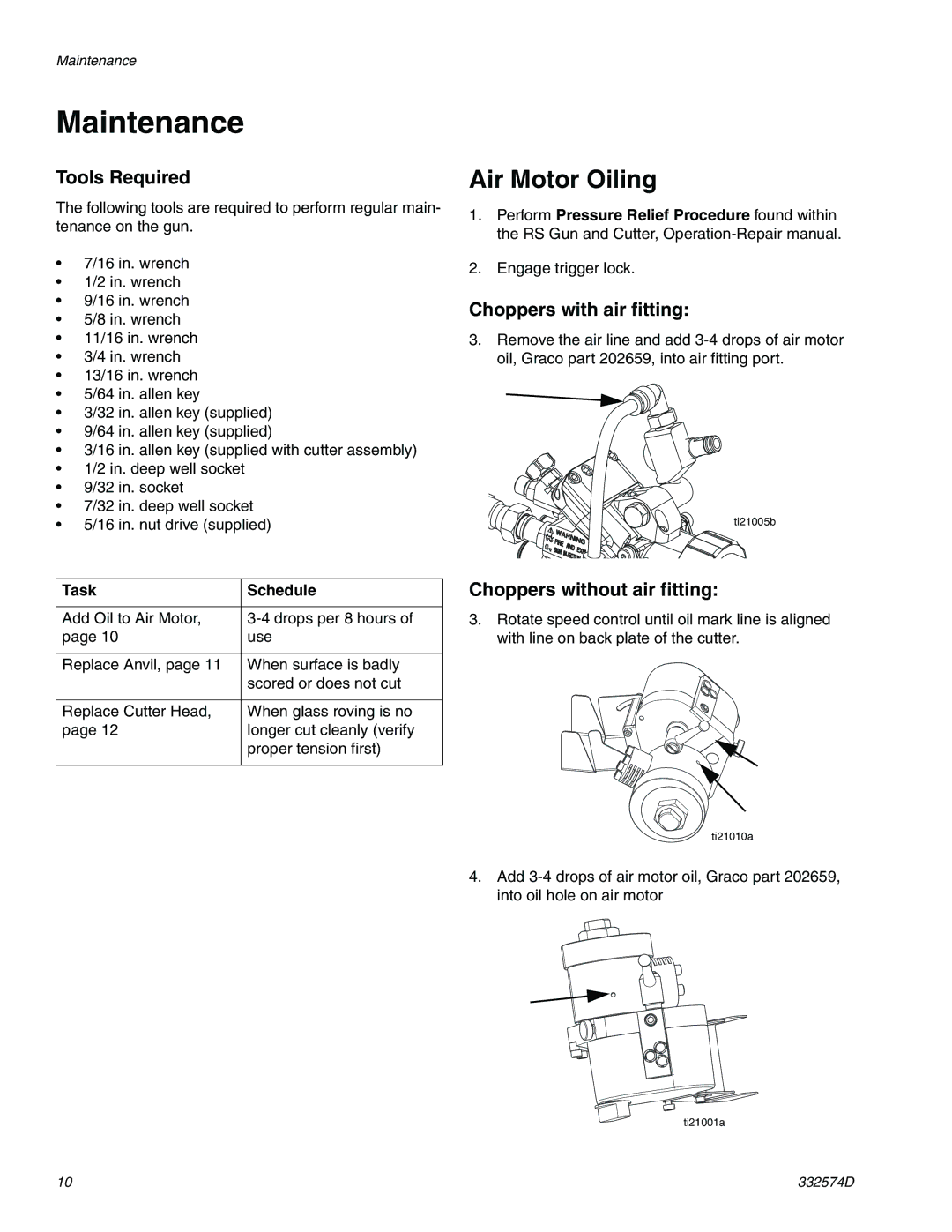

Choppers with air fitting:

3.Remove the air line and add

ti21005b

Choppers without air fitting:

3.Rotate speed control until oil mark line is aligned with line on back plate of the cutter.

ti21010a

4.Add

ti21001a

10 | 332574D |