Troubleshooting

Troubleshooting

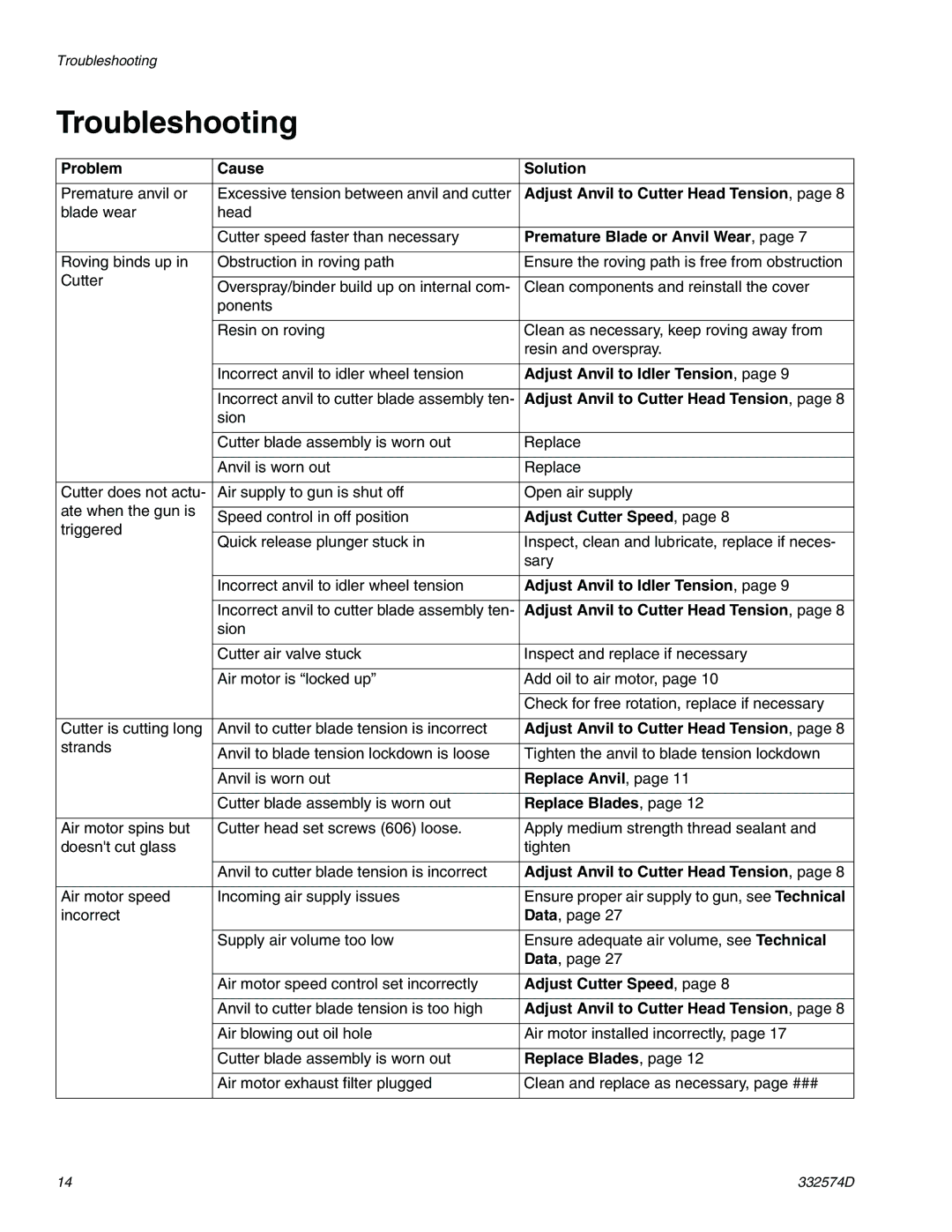

Problem | Cause | Solution | |

|

|

| |

Premature anvil or | Excessive tension between anvil and cutter | Adjust Anvil to Cutter Head Tension, page 8 | |

blade wear | head |

| |

|

|

| |

| Cutter speed faster than necessary | Premature Blade or Anvil Wear, page 7 | |

|

|

| |

Roving binds up in | Obstruction in roving path | Ensure the roving path is free from obstruction | |

Cutter |

|

| |

Overspray/binder build up on internal com- | Clean components and reinstall the cover | ||

| |||

| ponents |

| |

|

|

| |

| Resin on roving | Clean as necessary, keep roving away from | |

|

| resin and overspray. | |

|

|

| |

| Incorrect anvil to idler wheel tension | Adjust Anvil to Idler Tension, page 9 | |

|

|

| |

| Incorrect anvil to cutter blade assembly ten- | Adjust Anvil to Cutter Head Tension, page 8 | |

| sion |

| |

|

|

| |

| Cutter blade assembly is worn out | Replace | |

|

|

| |

| Anvil is worn out | Replace | |

|

|

| |

Cutter does not actu- | Air supply to gun is shut off | Open air supply | |

ate when the gun is |

|

| |

Speed control in off position | Adjust Cutter Speed, page 8 | ||

triggered | |||

|

| ||

Quick release plunger stuck in | Inspect, clean and lubricate, replace if neces- | ||

| |||

|

| sary | |

|

|

| |

| Incorrect anvil to idler wheel tension | Adjust Anvil to Idler Tension, page 9 | |

|

|

| |

| Incorrect anvil to cutter blade assembly ten- | Adjust Anvil to Cutter Head Tension, page 8 | |

| sion |

| |

|

|

| |

| Cutter air valve stuck | Inspect and replace if necessary | |

|

|

| |

| Air motor is “locked up” | Add oil to air motor, page 10 | |

|

|

| |

|

| Check for free rotation, replace if necessary | |

|

|

| |

Cutter is cutting long | Anvil to cutter blade tension is incorrect | Adjust Anvil to Cutter Head Tension, page 8 | |

strands |

|

| |

Anvil to blade tension lockdown is loose | Tighten the anvil to blade tension lockdown | ||

| |||

|

|

| |

| Anvil is worn out | Replace Anvil, page 11 | |

|

|

| |

| Cutter blade assembly is worn out | Replace Blades, page 12 | |

|

|

| |

Air motor spins but | Cutter head set screws (606) loose. | Apply medium strength thread sealant and | |

doesn't cut glass |

| tighten | |

|

|

| |

| Anvil to cutter blade tension is incorrect | Adjust Anvil to Cutter Head Tension, page 8 | |

|

|

| |

Air motor speed | Incoming air supply issues | Ensure proper air supply to gun, see Technical | |

incorrect |

| Data, page 27 | |

|

|

| |

| Supply air volume too low | Ensure adequate air volume, see Technical | |

|

| Data, page 27 | |

|

|

| |

| Air motor speed control set incorrectly | Adjust Cutter Speed, page 8 | |

|

|

| |

| Anvil to cutter blade tension is too high | Adjust Anvil to Cutter Head Tension, page 8 | |

|

|

| |

| Air blowing out oil hole | Air motor installed incorrectly, page 17 | |

|

|

| |

| Cutter blade assembly is worn out | Replace Blades, page 12 | |

|

|

| |

| Air motor exhaust filter plugged | Clean and replace as necessary, page ### | |

|

|

|

14 | 332574D |