Operation

Operation

Pressure Relief Procedure

INJECTION HAZARD

The system pressure must be manually relieved to pre- vent the system from starting or spraying accidentally. Fluid under high pressure can be injected through the skin and cause serious injury. To reduce the risk of an injury from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure whenever you:

•are instructed to relieve the pressure

•stop spraying

•check or service any of the system equipment

•install or clean the spray tip

FIRE AND EXPLOSION HAZARD

When Flushing system, always connect grounding cord.

RPS 2900 Pump Fluid Pressure Relief

1. Set hydraulic valve to OFF position.

4.Relieve hose pressure through guns. Use Program- mable Skipline Controller to trigger each gun for at least 3 seconds each.

NOTE: Always relieve pressure with the

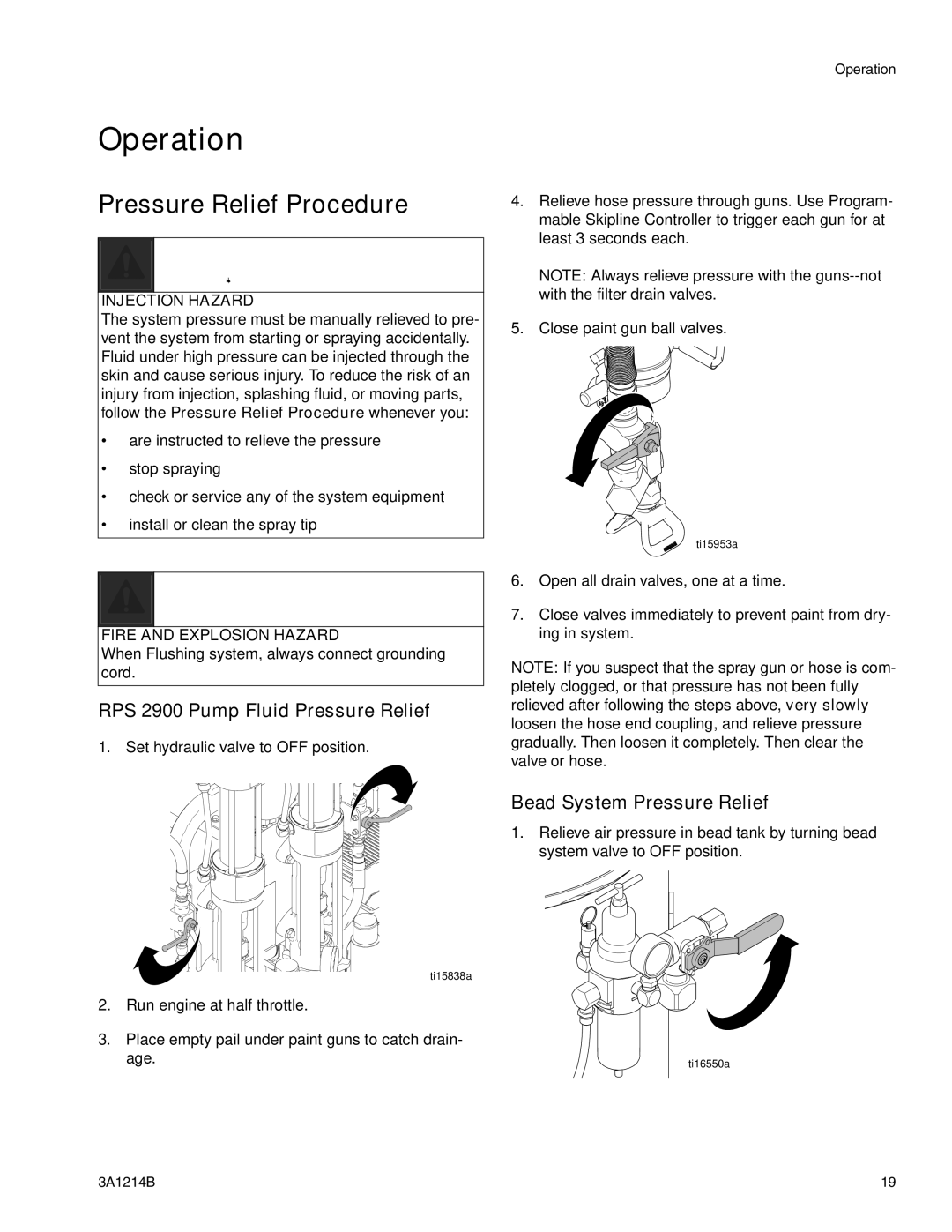

5.Close paint gun ball valves.

ti15953a

6.Open all drain valves, one at a time.

7.Close valves immediately to prevent paint from dry- ing in system.

NOTE: If you suspect that the spray gun or hose is com- pletely clogged, or that pressure has not been fully relieved after following the steps above, very slowly loosen the hose end coupling, and relieve pressure gradually. Then loosen it completely. Then clear the valve or hose.

Bead System Pressure Relief

1.Relieve air pressure in bead tank by turning bead system valve to OFF position.

| ti15838a |

|

2. | Run engine at half throttle. |

|

3. | Place empty pail under paint guns to catch drain- |

|

| age. | ti16550a |

3A1214B | 19 |