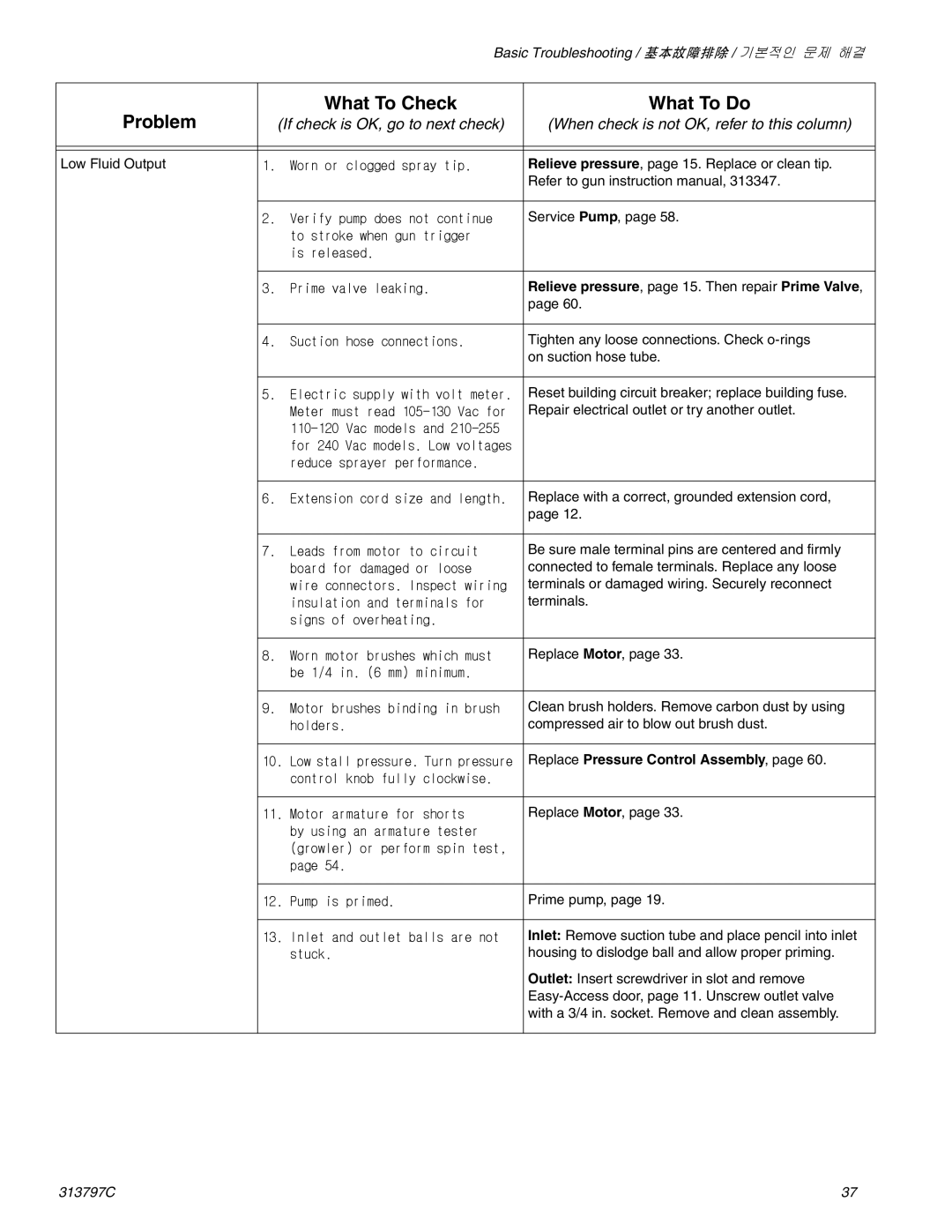

Basic Troubleshooting / 基本故障排除 / 기본적인 문제 해결

Problem |

| What To Check | What To Do |

| (If check is OK, go to next check) | (When check is not OK, refer to this column) | |

|

|

|

|

|

|

|

|

Low Fluid Output | 1. | Worn or clogged spray tip. | Relieve pressure, page 15. Replace or clean tip. |

|

|

| Refer to gun instruction manual, 313347. |

|

|

|

|

| 2. | Verify pump does not continue | Service Pump, page 58. |

|

| to stroke when gun trigger |

|

|

| is released. |

|

|

|

|

|

| 3. | Prime valve leaking. | Relieve pressure, page 15. Then repair Prime Valve, |

|

|

| page 60. |

|

|

|

|

| 4. | Suction hose connections. | Tighten any loose connections. Check |

|

|

| on suction hose tube. |

5.Electric supply with volt meter. Reset building circuit breaker; replace building fuse.

Meter must read | Repair electrical outlet or try another outlet. | |

Vac models and |

| |

for 240 | Vac models. Low voltages |

|

reduce sprayer performance. |

| |

6.Extension cord size and length. Replace with a correct, grounded extension cord,

page 12.

7. | Leads from motor to circuit | Be sure male terminal pins are centered and firmly |

| board for damaged or loose | connected to female terminals. Replace any loose |

| wire connectors. Inspect wiring | terminals or damaged wiring. Securely reconnect |

| insulation and terminals for | terminals. |

| signs of overheating. |

|

|

|

|

8. | Worn motor brushes which must | Replace Motor, page 33. |

| be 1/4 in. (6 mm) minimum. |

|

|

|

|

9. | Motor brushes binding in brush | Clean brush holders. Remove carbon dust by using |

| holders. | compressed air to blow out brush dust. |

|

|

|

10. | Low stall pressure. Turn pressure | Replace Pressure Control Assembly, page 60. |

| control knob fully clockwise. |

|

|

|

|

11. | Motor armature for shorts | Replace Motor, page 33. |

| by using an armature tester |

|

| (growler) or perform spin test, |

|

| page 54. |

|

|

|

|

12. | Pump is primed. | Prime pump, page 19. |

|

|

|

13. | Inlet and outlet balls are not | Inlet: Remove suction tube and place pencil into inlet |

| stuck. | housing to dislodge ball and allow proper priming. |

|

| Outlet: Insert screwdriver in slot and remove |

|

| |

|

| with a 3/4 in. socket. Remove and clean assembly. |

313797C | 37 |