Service

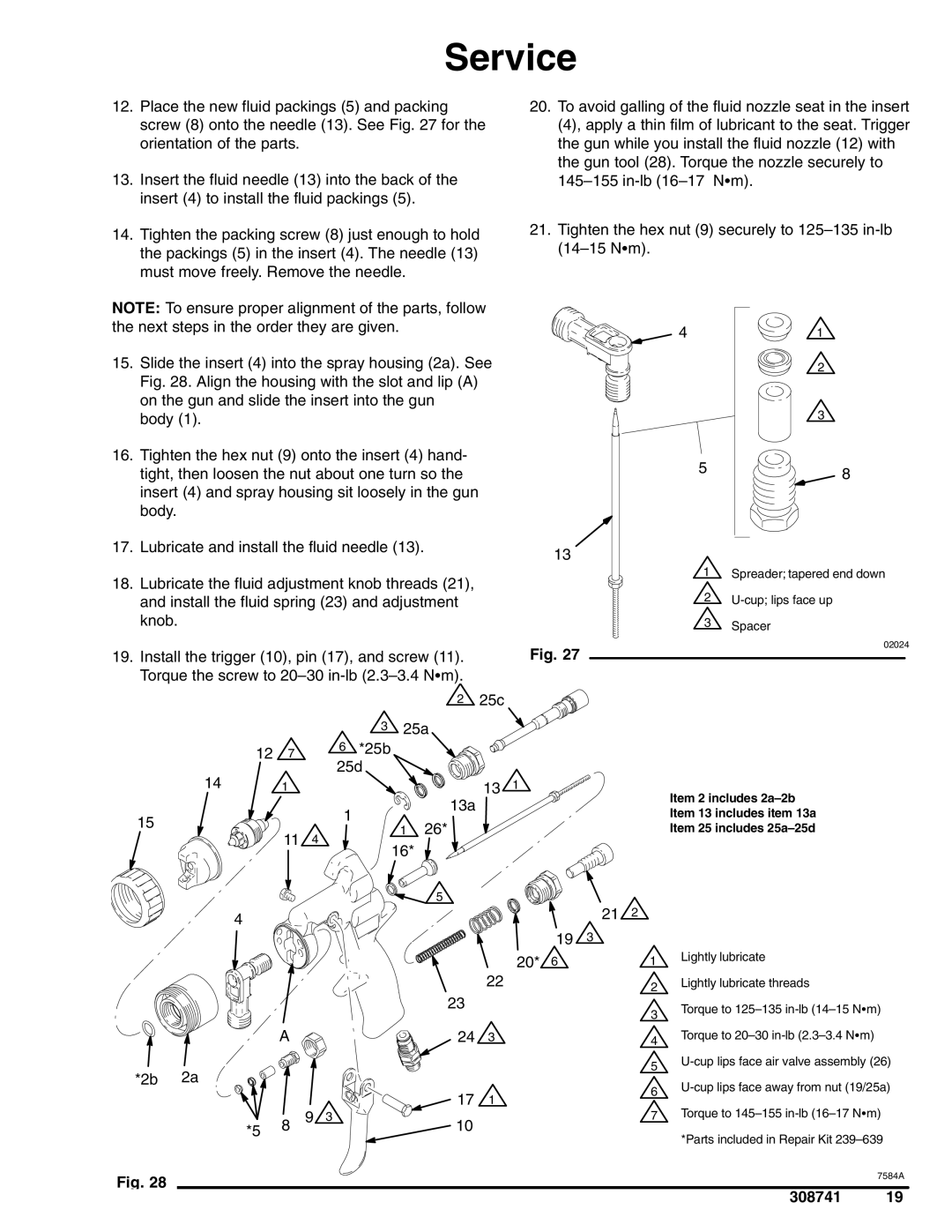

12.Place the new fluid packings (5) and packing screw (8) onto the needle (13). See Fig. 27 for the orientation of the parts.

13.Insert the fluid needle (13) into the back of the insert (4) to install the fluid packings (5).

14.Tighten the packing screw (8) just enough to hold the packings (5) in the insert (4). The needle (13) must move freely. Remove the needle.

NOTE: To ensure proper alignment of the parts, follow the next steps in the order they are given.

15.Slide the insert (4) into the spray housing (2a). See Fig. 28. Align the housing with the slot and lip (A) on the gun and slide the insert into the gun

body (1).

16.Tighten the hex nut (9) onto the insert (4) hand- tight, then loosen the nut about one turn so the insert (4) and spray housing sit loosely in the gun body.

17.Lubricate and install the fluid needle (13).

18.Lubricate the fluid adjustment knob threads (21), and install the fluid spring (23) and adjustment knob.

20.To avoid galling of the fluid nozzle seat in the insert (4), apply a thin film of lubricant to the seat. Trigger the gun while you install the fluid nozzle (12) with the gun tool (28). Torque the nozzle securely to

21.Tighten the hex nut (9) securely to

41

2

3

58

13

1Spreader; tapered end down

2

3Spacer

19. Install the trigger (10), pin (17), and screw (11). |

| Fig. 27 | |||||

Torque the screw to |

|

| |||||

|

|

|

|

| 2 | 25c |

|

|

|

| 3 | 25a |

|

| |

12 | 7 | 6 | *25b |

|

|

|

|

25d |

|

|

|

| |||

14 |

|

|

|

|

| ||

1 |

|

|

| 13a | 13 | 1 | |

15 |

| 1 |

|

|

|

| |

|

| 1 | 26* |

|

| ||

11 |

|

|

|

| |||

| 4 |

|

|

| |||

|

| 16* |

|

|

| ||

|

|

|

|

|

|

| |

|

|

|

|

| 5 |

|

|

02024

Item 2 includes

Item 13 includes item 13a

Item 25 includes

4 |

|

|

|

|

| 21 | 2 |

|

|

|

|

|

|

|

|

| |

|

|

|

|

| 19 | 3 |

|

|

|

|

|

|

| 20* 6 |

| 1 | Lightly lubricate |

|

|

|

|

| 22 |

| 2 | Lightly lubricate threads |

|

|

|

| 23 |

|

|

| |

|

|

|

|

|

| 3 | Torque to | |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

| A |

|

| 24 | 3 |

| 4 | Torque to |

*2b 2a |

|

|

|

|

|

| 5 | |

|

|

|

|

|

|

| ||

|

|

|

|

|

| 6 | ||

|

|

|

| 17 | 1 |

| ||

|

|

|

|

|

| |||

|

| 9 |

|

| 7 | Torque to | ||

*5 | 8 | 3 | 10 |

|

| |||

|

|

|

|

| *Parts included in Repair Kit | |||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

Fig. 28 | 7584A |

|