Setup

6. Adjust the Spray Pattern (continued)

B.Adjust the fluid flow using the fluid pressure regulator (L) installed in the gun fluid line. Typical industrial flow rates will vary with regulator pres- sures from 5 to 30 psi (34 to 210 kPa, 0.3 to 2.1 bar).

L

7019A

Fig. 8

C.Hold the gun parallel to the floor and adjust the fluid pressure to yield a 1 to 6 inch (25.4 to 152.4 mm) straight fluid stream before the stream falls off.

7037A

Fig. 9

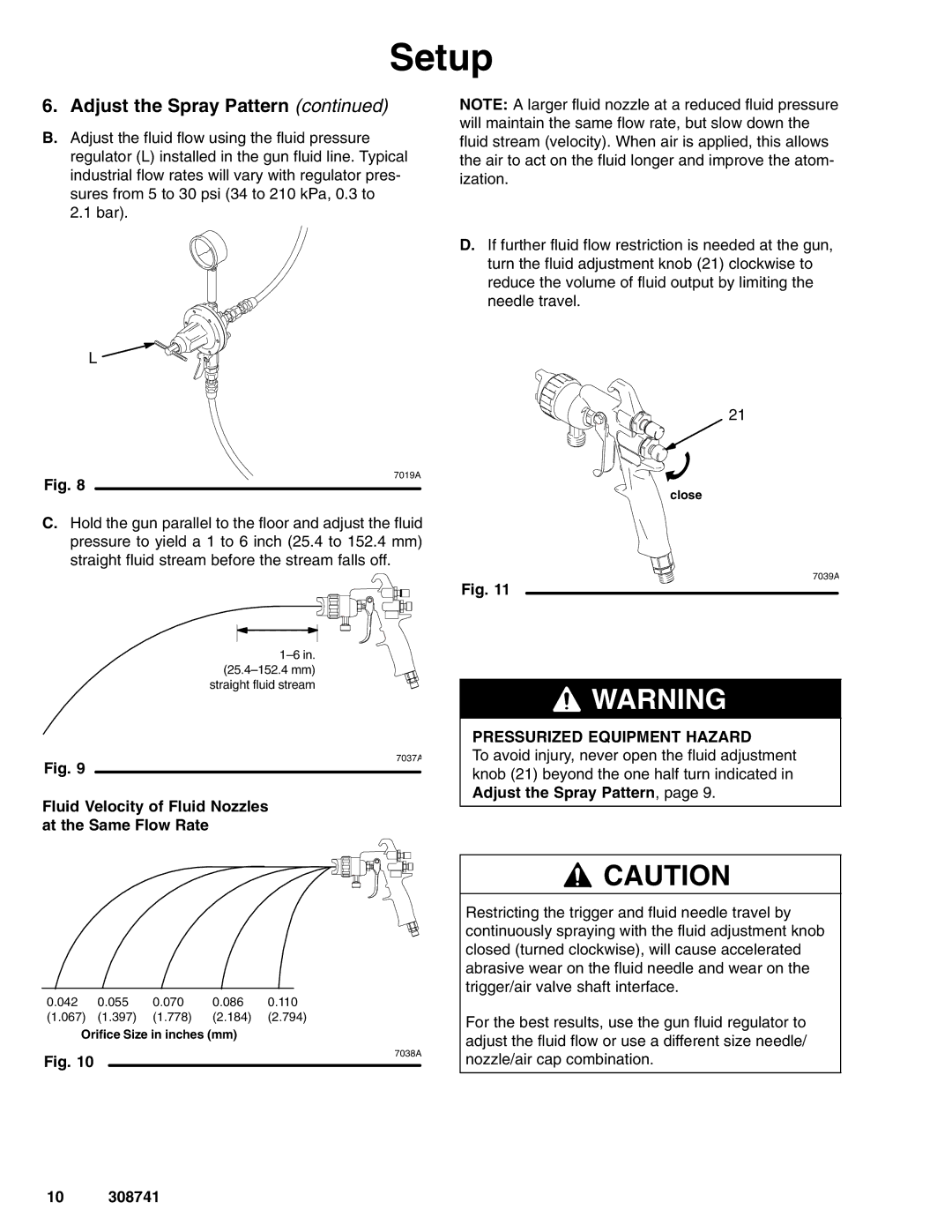

Fluid Velocity of Fluid Nozzles

at the Same Flow Rate

NOTE: A larger fluid nozzle at a reduced fluid pressure will maintain the same flow rate, but slow down the fluid stream (velocity). When air is applied, this allows the air to act on the fluid longer and improve the atom- ization.

D.If further fluid flow restriction is needed at the gun, turn the fluid adjustment knob (21) clockwise to reduce the volume of fluid output by limiting the needle travel.

21

close

7039A

Fig. 11

![]() WARNING

WARNING

PRESSURIZED EQUIPMENT HAZARD

To avoid injury, never open the fluid adjustment knob (21) beyond the one half turn indicated in Adjust the Spray Pattern, page 9.

0.042 | 0.055 | 0.070 | 0.086 | 0.110 |

(1.067) | (1.397) | (1.778) | (2.184) | (2.794) |

Orifice Size in inches (mm)

![]() CAUTION

CAUTION

Restricting the trigger and fluid needle travel by continuously spraying with the fluid adjustment knob closed (turned clockwise), will cause accelerated abrasive wear on the fluid needle and wear on the trigger/air valve shaft interface.

For the best results, use the gun fluid regulator to adjust the fluid flow or use a different size needle/

Fig. 10

7038A

nozzle/air cap combination.

10 308741