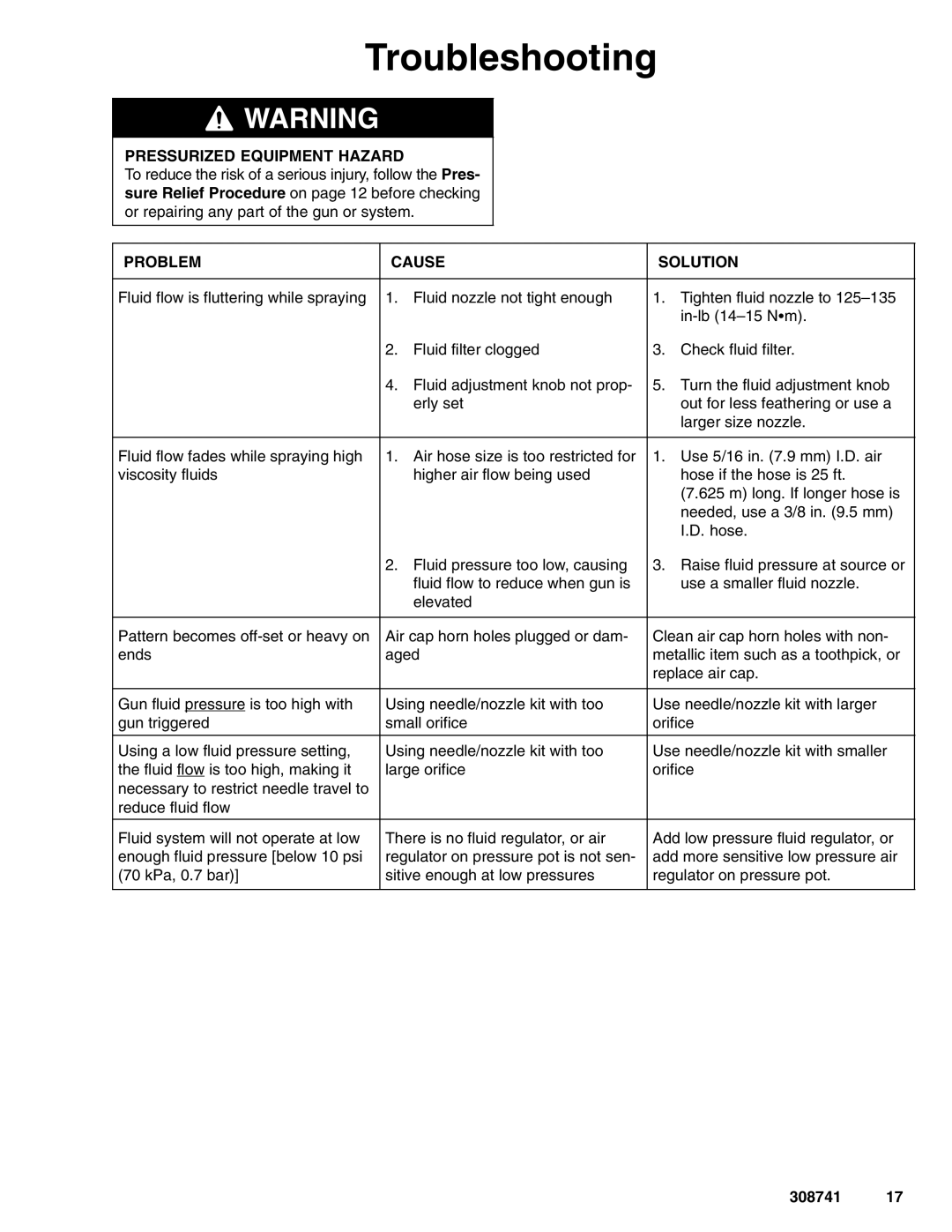

Troubleshooting

![]() WARNING

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of a serious injury, follow the Pres- sure Relief Procedure on page 12 before checking or repairing any part of the gun or system.

PROBLEM | CAUSE | SOLUTION | |

|

|

|

|

Fluid flow is fluttering while spraying | 1. | Fluid nozzle not tight enough | 1. Tighten fluid nozzle to |

|

|

| |

| 2. | Fluid filter clogged | 3. Check fluid filter. |

| 4. Fluid adjustment knob not prop- | 5. Turn the fluid adjustment knob | |

|

| erly set | out for less feathering or use a |

|

|

| larger size nozzle. |

|

|

| |

Fluid flow fades while spraying high | 1. Air hose size is too restricted for | 1. Use 5/16 in. (7.9 mm) I.D. air | |

viscosity fluids |

| higher air flow being used | hose if the hose is 25 ft. |

|

|

| (7.625 m) long. If longer hose is |

|

|

| needed, use a 3/8 in. (9.5 mm) |

|

|

| I.D. hose. |

| 2. Fluid pressure too low, causing | 3. Raise fluid pressure at source or | |

|

| fluid flow to reduce when gun is | use a smaller fluid nozzle. |

|

| elevated |

|

|

|

| |

Pattern becomes | Air cap horn holes plugged or dam- | Clean air cap horn holes with non- | |

ends | aged | metallic item such as a toothpick, or | |

|

|

| replace air cap. |

|

|

| |

Gun fluid pressure is too high with | Using needle/nozzle kit with too | Use needle/nozzle kit with larger | |

gun triggered | small orifice | orifice | |

|

|

| |

Using a low fluid pressure setting, | Using needle/nozzle kit with too | Use needle/nozzle kit with smaller | |

the fluid flow is too high, making it | large orifice | orifice | |

necessary to restrict needle travel to |

|

|

|

reduce fluid flow |

|

|

|

|

|

| |

Fluid system will not operate at low | There is no fluid regulator, or air | Add low pressure fluid regulator, or | |

enough fluid pressure [below 10 psi | regulator on pressure pot is not sen- | add more sensitive low pressure air | |

(70 kPa, 0.7 bar)] | sitive enough at low pressures | regulator on pressure pot. | |

|

|

|

|