Clean the Air Cap and Fluid Nozzle

Equipment Needed

•soft bristle brush

•

Procedure

1. Turn the ES ON/OFF valve OFF. Wait 30 seconds.

I ES O

ti1273a

2.Discharge the system voltage (page 20).

3.Relieve the pressure (page 20).

ti1276a

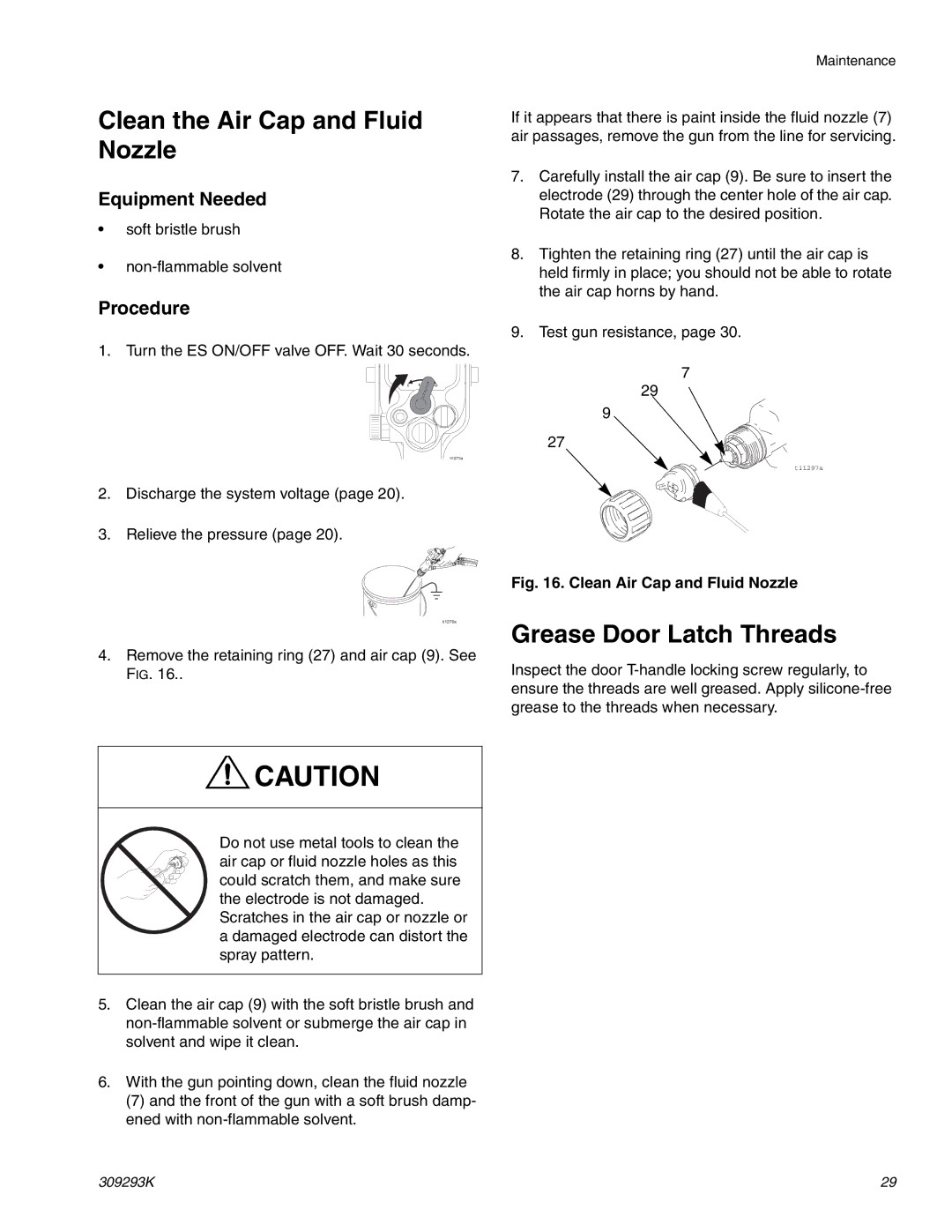

4.Remove the retaining ring (27) and air cap (9). See FIG. 16..

![]() CAUTION

CAUTION

Do not use metal tools to clean the air cap or fluid nozzle holes as this could scratch them, and make sure the electrode is not damaged.

Scratches in the air cap or nozzle or a damaged electrode can distort the spray pattern.

5.Clean the air cap (9) with the soft bristle brush and

6.With the gun pointing down, clean the fluid nozzle

(7) and the front of the gun with a soft brush damp- ened with

Maintenance

If it appears that there is paint inside the fluid nozzle (7) air passages, remove the gun from the line for servicing.

7.Carefully install the air cap (9). Be sure to insert the electrode (29) through the center hole of the air cap. Rotate the air cap to the desired position.

8.Tighten the retaining ring (27) until the air cap is held firmly in place; you should not be able to rotate the air cap horns by hand.

9.Test gun resistance, page 30.

7

29

9

27

ti1297a

Fig. 16. Clean Air Cap and Fluid Nozzle

Grease Door Latch Threads

Inspect the door

309293K | 29 |