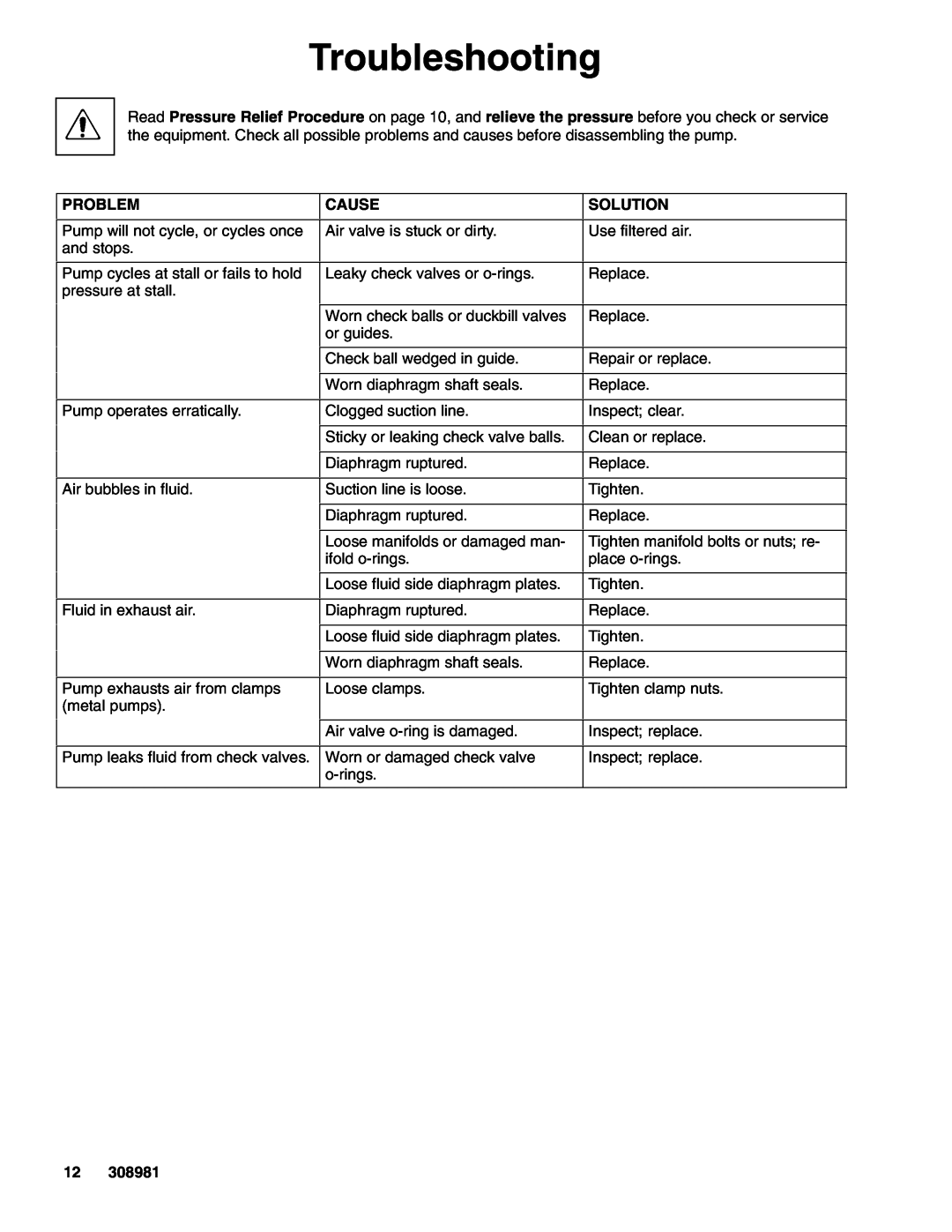

Troubleshooting

Read Pressure Relief Procedure on page 10, and relieve the pressure before you check or service the equipment. Check all possible problems and causes before disassembling the pump.

PROBLEM | CAUSE | SOLUTION |

|

|

|

Pump will not cycle, or cycles once | Air valve is stuck or dirty. | Use filtered air. |

and stops. |

|

|

|

|

|

Pump cycles at stall or fails to hold | Leaky check valves or | Replace. |

pressure at stall. |

|

|

|

|

|

| Worn check balls or duckbill valves | Replace. |

| or guides. |

|

|

|

|

| Check ball wedged in guide. | Repair or replace. |

|

|

|

| Worn diaphragm shaft seals. | Replace. |

|

|

|

Pump operates erratically. | Clogged suction line. | Inspect; clear. |

|

|

|

| Sticky or leaking check valve balls. | Clean or replace. |

|

|

|

| Diaphragm ruptured. | Replace. |

|

|

|

Air bubbles in fluid. | Suction line is loose. | Tighten. |

|

|

|

| Diaphragm ruptured. | Replace. |

|

|

|

| Loose manifolds or damaged man- | Tighten manifold bolts or nuts; re- |

| ifold | place |

|

|

|

| Loose fluid side diaphragm plates. | Tighten. |

|

|

|

Fluid in exhaust air. | Diaphragm ruptured. | Replace. |

|

|

|

| Loose fluid side diaphragm plates. | Tighten. |

|

|

|

| Worn diaphragm shaft seals. | Replace. |

|

|

|

Pump exhausts air from clamps | Loose clamps. | Tighten clamp nuts. |

(metal pumps). |

|

|

|

|

|

| Air valve | Inspect; replace. |

|

|

|

Pump leaks fluid from check valves. | Worn or damaged check valve | Inspect; replace. |

|

| |

|

|

|

12 308981