Installation

Fluid Pressure Relief Valve

![]() CAUTION

CAUTION

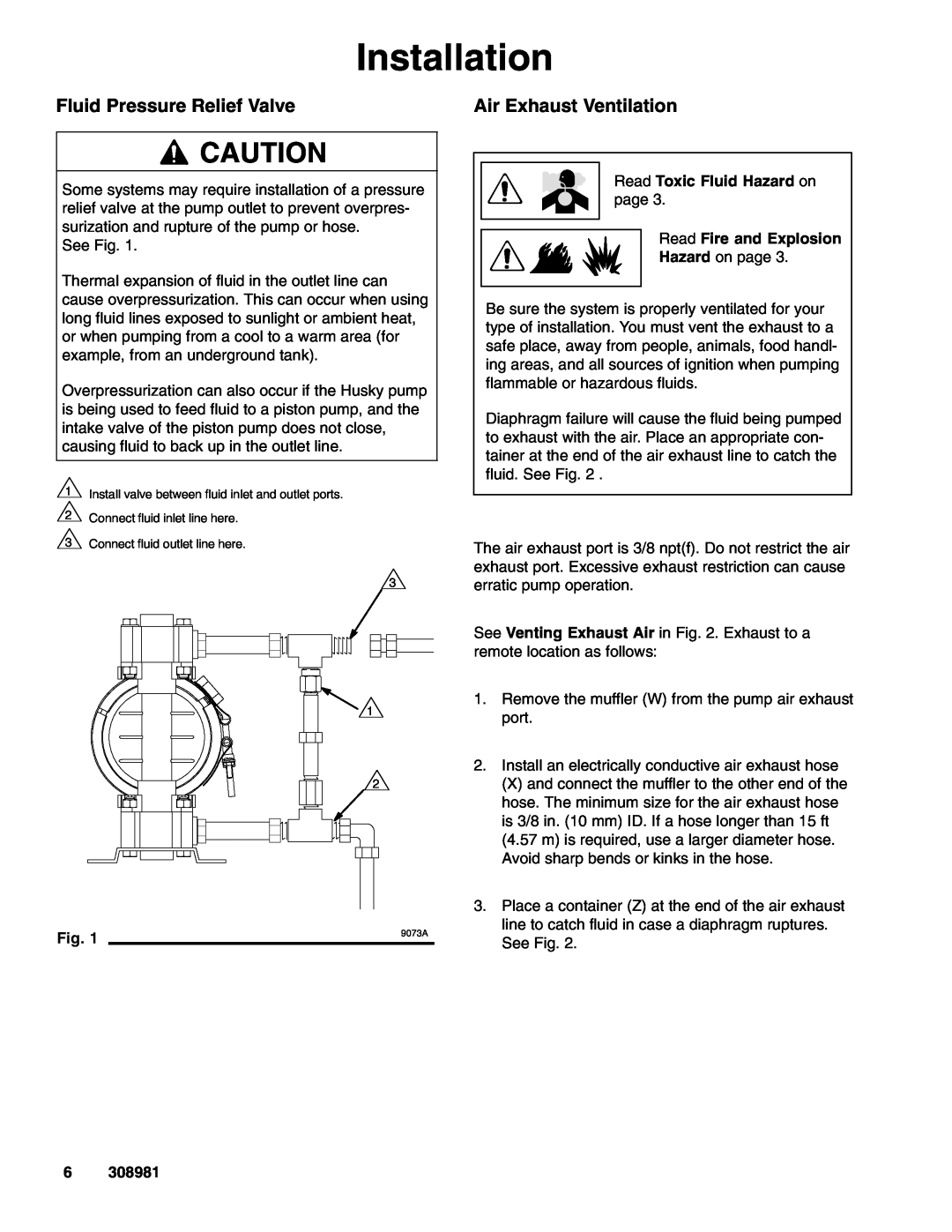

Some systems may require installation of a pressure relief valve at the pump outlet to prevent overpres- surization and rupture of the pump or hose.

See Fig. 1.

Thermal expansion of fluid in the outlet line can cause overpressurization. This can occur when using long fluid lines exposed to sunlight or ambient heat, or when pumping from a cool to a warm area (for example, from an underground tank).

Overpressurization can also occur if the Husky pump is being used to feed fluid to a piston pump, and the intake valve of the piston pump does not close, causing fluid to back up in the outlet line.

1Install valve between fluid inlet and outlet ports.

2Connect fluid inlet line here.

3Connect fluid outlet line here.

3

1

2

| 9073A |

Fig. 1 |

Air Exhaust Ventilation

Read Toxic Fluid Hazard on page 3.

Read Fire and Explosion

Hazard on page 3.

Be sure the system is properly ventilated for your type of installation. You must vent the exhaust to a safe place, away from people, animals, food handl- ing areas, and all sources of ignition when pumping flammable or hazardous fluids.

Diaphragm failure will cause the fluid being pumped to exhaust with the air. Place an appropriate con- tainer at the end of the air exhaust line to catch the fluid. See Fig. 2 .

The air exhaust port is 3/8 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can cause erratic pump operation.

See Venting Exhaust Air in Fig. 2. Exhaust to a remote location as follows:

1.Remove the muffler (W) from the pump air exhaust port.

2.Install an electrically conductive air exhaust hose

(X) and connect the muffler to the other end of the hose. The minimum size for the air exhaust hose is 3/8 in. (10 mm) ID. If a hose longer than 15 ft (4.57 m) is required, use a larger diameter hose. Avoid sharp bends or kinks in the hose.

3.Place a container (Z) at the end of the air exhaust line to catch fluid in case a diaphragm ruptures. See Fig. 2.

6 308981