SERVICE ENGINE

Service Engine

Avoid Fumes

cCAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause serious illness or death.

Move the vehicle to an outside area before running the engine.

Do not run an engine in an enclosed area without adequate ventilation.

•Connect a pipe extension to the engine exhaust pipe to direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the exhaust fumes out.

Engine Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

Use oil that meets the following specification:

•See the engine manufacturer’s owner’s manual provided with your machine for the correct specifications.

Checking Engine Oil Level

IMPORTANT: Avoid damage! Failure to check the oil level regularly could lead to serious engine problems if oil level is low:

•Check oil level before operating.

•Check oil level when the engine is cold and not running.

•Keep level between the FULL and the ADD marks.

•Shut off engine before adding oil.

NOTE: Check oil twice a day if the engine runs over four hours in a day.

Make sure engine is cold when checking engine oil level.

1.Park machine safely. (See Parking Safely in the Safety section.)

2.Allow engine to cool.

3.Clean area around dipstick to prevent debris from falling into crankcase.

4.Remove dipstick (A). Wipe with a clean cloth.

5.Install dipstick and allow the cap to rest on the end of the tube. Do not tighten the cap.

IMPORTANT: Avoid damage! To prevent extensive engine wear or damage, always maintain the proper engine oil level. Never operate the engine with the oil level below the ADD mark or over the FULL mark.

6.Remove dipstick and check oil level on dipstick. Oil must be between the ADD and FULL marks.

•If oil is low, add oil to bring oil level no higher than the FULL mark on dipstick.

•If oil level is above the FULL mark, drain to proper level.

7.Install and tighten dipstick.

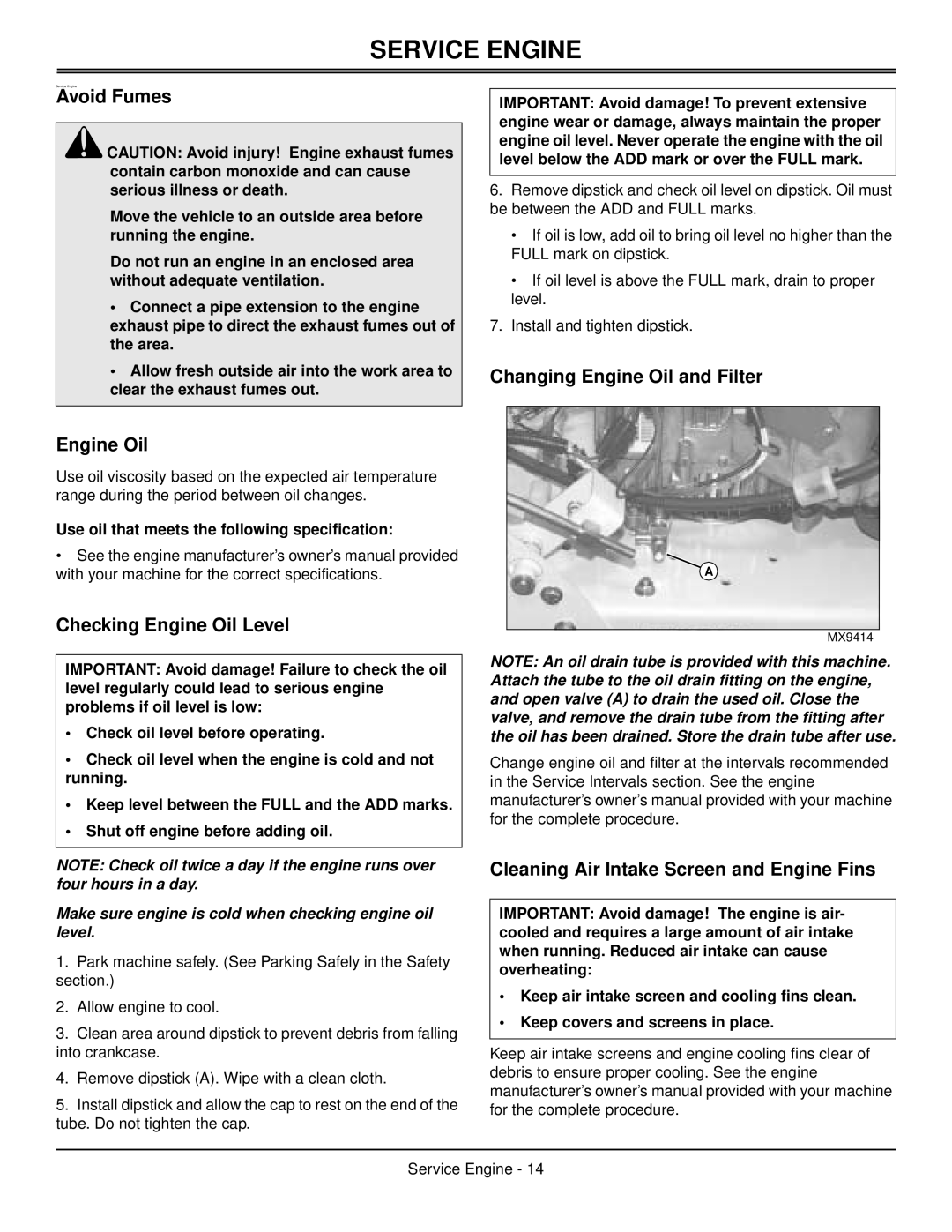

Changing Engine Oil and Filter

A

MX9414

NOTE: An oil drain tube is provided with this machine. Attach the tube to the oil drain fitting on the engine, and open valve (A) to drain the used oil. Close the valve, and remove the drain tube from the fitting after the oil has been drained. Store the drain tube after use.

Change engine oil and filter at the intervals recommended in the Service Intervals section. See the engine manufacturer’s owner’s manual provided with your machine for the complete procedure.

Cleaning Air Intake Screen and Engine Fins

IMPORTANT: Avoid damage! The engine is air- cooled and requires a large amount of air intake when running. Reduced air intake can cause overheating:

•Keep air intake screen and cooling fins clean.

•Keep covers and screens in place.

Keep air intake screens and engine cooling fins clear of debris to ensure proper cooling. See the engine manufacturer’s owner’s manual provided with your machine for the complete procedure.

Service Engine - 14