SECTION 4: OPERATIONS

Operation Safety |

| Depth of Cut |

|

|

|

|

|

|

Damage to your eyes, lungs, and ears could result from using this machine without proper protective gear. Always wear safety glasses, a respirator, and hearing protection when operating this machine.

Loose hair and cloth-

ing could get caught in

![]() machinery and cause seri-

machinery and cause seri-

ous personal injury. Keep

loose clothing and long

hair away from moving machinery.

NOTICE

If you have never used this type of machine or equipment before, WE STRONGLY REC- OMMEND that you read books, trade maga- zines, or get formal training before begin- ning any projects. Regardless of the con- tent in this section, Grizzly Industrial will not be held liable for accidents caused by lack of training.

G0449/G0450 37" Drum Sander

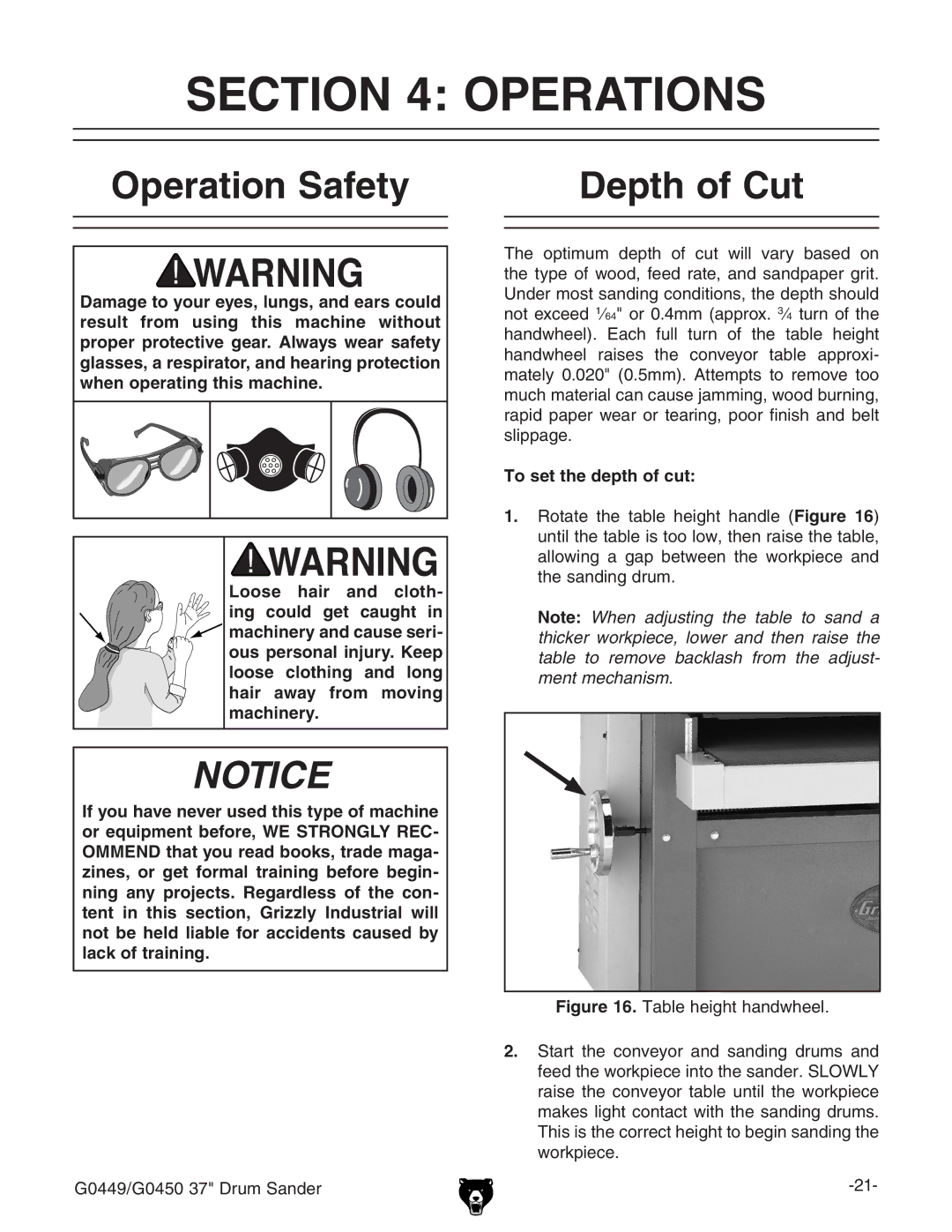

The optimum depth of cut will vary based on the type of wood, feed rate, and sandpaper grit. Under most sanding conditions, the depth should not exceed 1⁄64" or 0.4mm (approx. 3⁄4 turn of the handwheel). Each full turn of the table height handwheel raises the conveyor table approxi- mately 0.020" (0.5mm). Attempts to remove too much material can cause jamming, wood burning, rapid paper wear or tearing, poor finish and belt slippage.

To set the depth of cut:

1.Rotate the table height handle (Figure 16) until the table is too low, then raise the table, allowing a gap between the workpiece and the sanding drum.

Note: When adjusting the table to sand a thicker workpiece, lower and then raise the table to remove backlash from the adjust- ment mechanism.