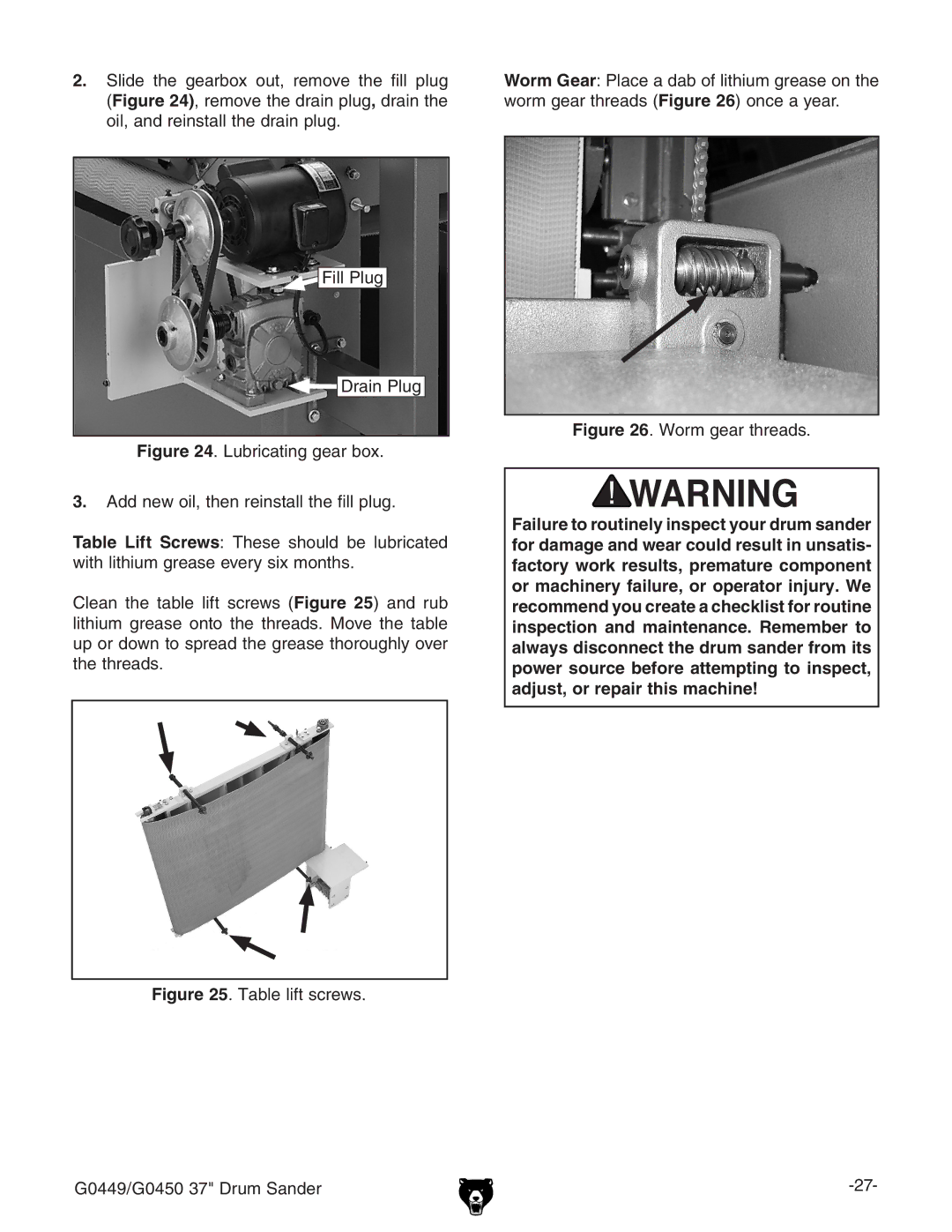

2.Slide the gearbox out, remove the fill plug (Figure 24), remove the drain plug, drain the oil, and reinstall the drain plug.

Worm Gear: Place a dab of lithium grease on the worm gear threads (Figure 26) once a year.

![]() Fill Plug

Fill Plug

Drain Plug

Figure 24. Lubricating gear box.

3.Add new oil, then reinstall the fill plug.

Table Lift Screws: These should be lubricated with lithium grease every six months.

Clean the table lift screws (Figure 25) and rub lithium grease onto the threads. Move the table up or down to spread the grease thoroughly over the threads.

Figure 26. Worm gear threads.

Failure to routinely inspect your drum sander for damage and wear could result in unsatis- factory work results, premature component or machinery failure, or operator injury. We recommend you create a checklist for routine inspection and maintenance. Remember to always disconnect the drum sander from its power source before attempting to inspect, adjust, or repair this machine!

Figure 25. Table lift screws.

G0449/G0450 37" Drum Sander |