Adjusting Feed Rate

NOTICE

The conveyor track must be moving when adjusting the feed rate.

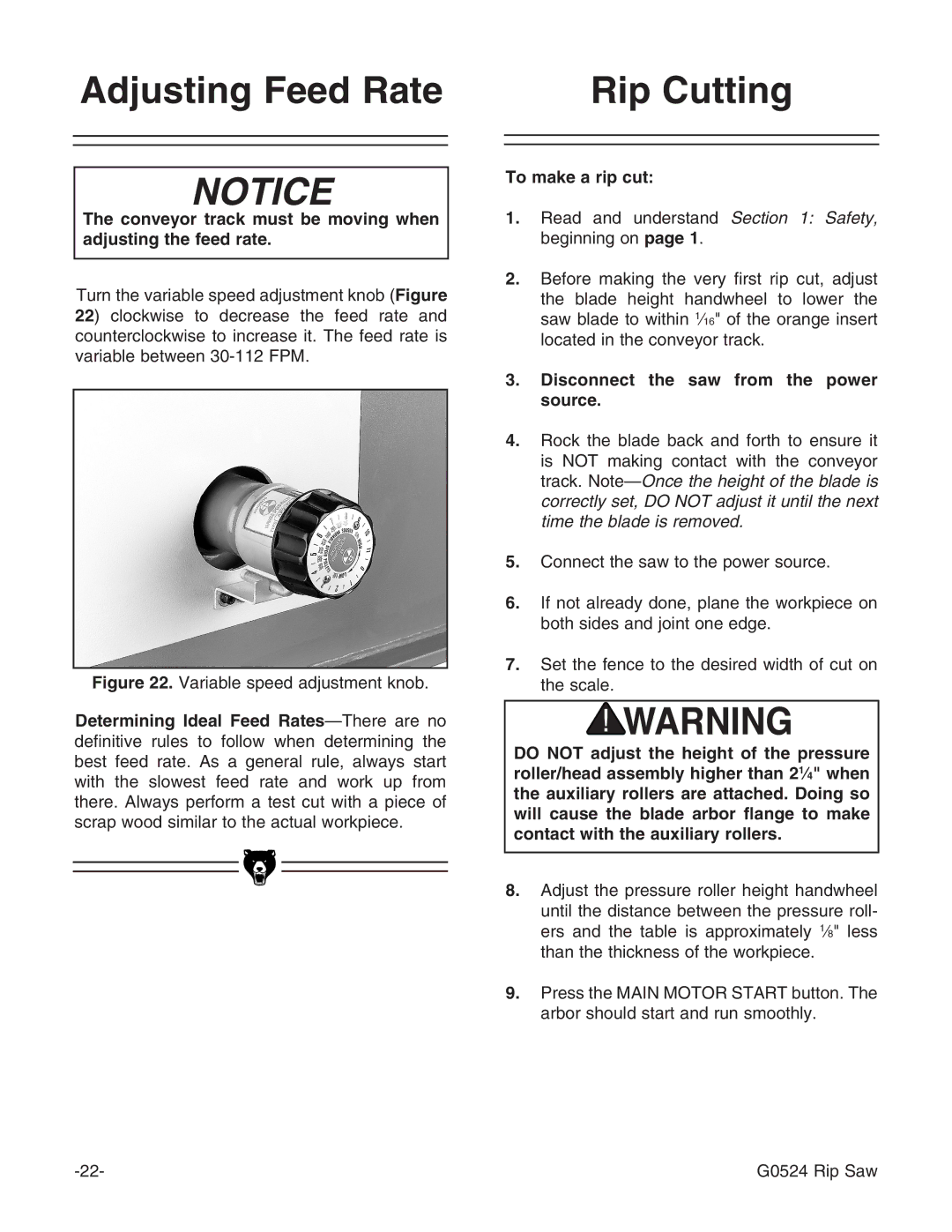

Turn the variable speed adjustment knob (Figure 22) clockwise to decrease the feed rate and counterclockwise to increase it. The feed rate is variable between

Figure 22. Variable speed adjustment knob.

Determining Ideal Feed Rates—There are no definitive rules to follow when determining the best feed rate. As a general rule, always start with the slowest feed rate and work up from there. Always perform a test cut with a piece of scrap wood similar to the actual workpiece.

Rip Cutting

To make a rip cut:

1.Read and understand Section 1: Safety, beginning on page 1.

2.Before making the very first rip cut, adjust the blade height handwheel to lower the saw blade to within 1⁄16" of the orange insert located in the conveyor track.

3.Disconnect the saw from the power source.

4.Rock the blade back and forth to ensure it is NOT making contact with the conveyor track.

5.Connect the saw to the power source.

6.If not already done, plane the workpiece on both sides and joint one edge.

7.Set the fence to the desired width of cut on the scale.

DO NOT adjust the height of the pressure roller/head assembly higher than 21⁄4" when the auxiliary rollers are attached. Doing so will cause the blade arbor flange to make contact with the auxiliary rollers.

8.Adjust the pressure roller height handwheel until the distance between the pressure roll- ers and the table is approximately 1⁄8" less than the thickness of the workpiece.

9.Press the MAIN MOTOR START button. The arbor should start and run smoothly.

G0524 Rip Saw |