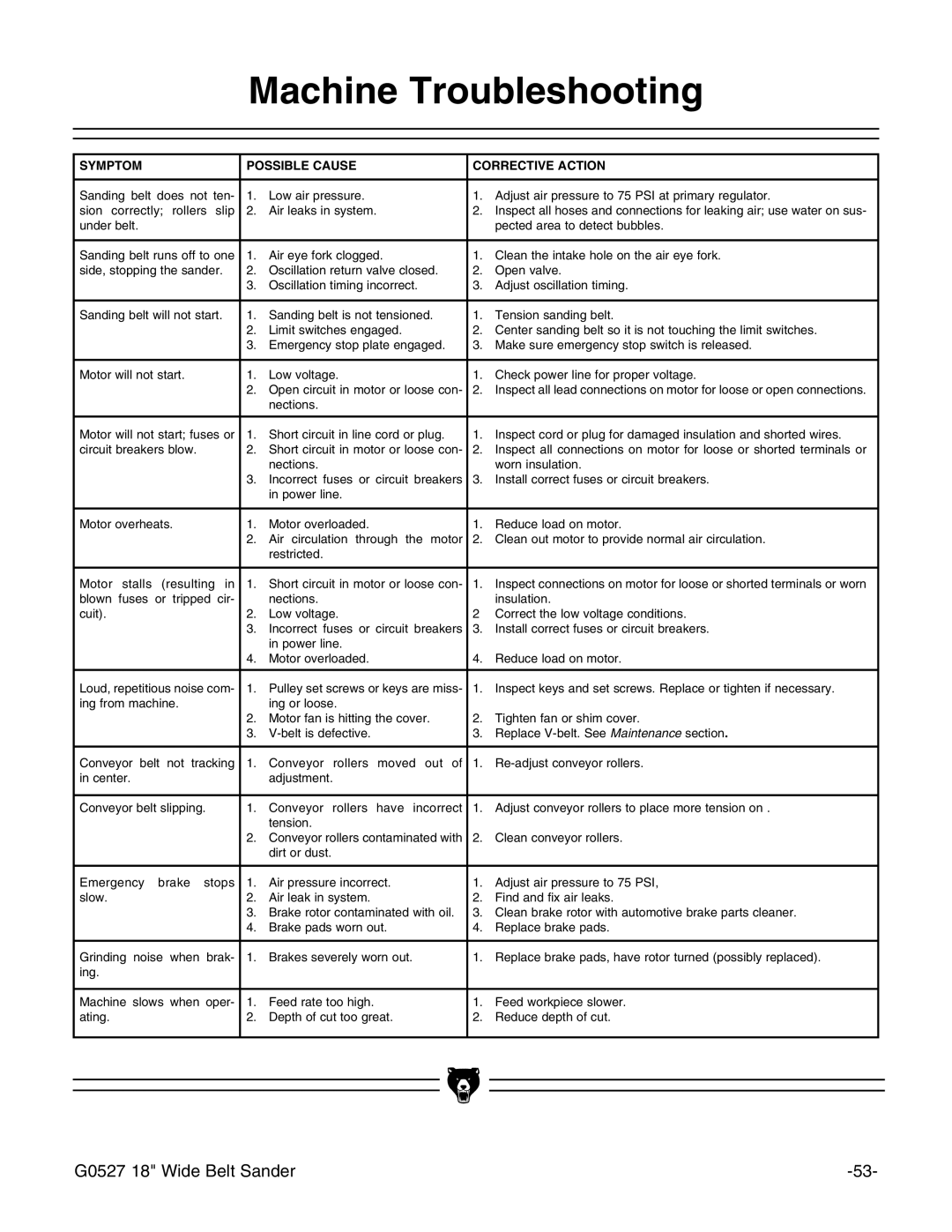

Machine Troubleshooting

SYMPTOM |

|

| POSSIBLE CAUSE | CORRECTIVE ACTION |

| |||||

|

|

|

|

|

|

|

|

| ||

Sanding belt does not ten- | 1. | Low air pressure. | 1. |

| Adjust air pressure to 75 PSI at primary regulator. |

| ||||

sion correctly; rollers slip | 2. | Air leaks in system. | 2. |

| Inspect all hoses and connections for leaking air; use water on sus- |

| ||||

under belt. |

|

|

|

|

|

|

|

| pected area to detect bubbles. |

|

|

|

|

|

|

|

|

|

| ||

Sanding belt runs off to one | 1. | Air eye fork clogged. | 1. |

| Clean the intake hole on the air eye fork. |

| ||||

side, stopping the sander. | 2. | Oscillation return valve closed. | 2. |

| Open valve. |

| ||||

|

|

| 3. | Oscillation timing incorrect. | 3. |

| Adjust oscillation timing. |

| ||

|

|

|

|

|

|

|

|

| ||

Sanding belt will not start. | 1. | Sanding belt is not tensioned. | 1. |

| Tension sanding belt. |

| ||||

|

|

| 2. | Limit switches engaged. | 2. |

| Center sanding belt so it is not touching the limit switches. |

| ||

|

|

| 3. | Emergency stop plate engaged. | 3. |

| Make sure emergency stop switch is released. |

| ||

|

|

|

|

|

|

|

|

|

| |

Motor will not start. |

| 1. | Low voltage. | 1. |

| Check power line for proper voltage. |

| |||

|

|

| 2. | Open circuit in motor or loose con- | 2. |

| Inspect all lead connections on motor for loose or open connections. |

| ||

|

|

|

| nections. |

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

Motor will not start; fuses or | 1. | Short circuit in line cord or plug. | 1. |

| Inspect cord or plug for damaged insulation and shorted wires. |

| ||||

circuit breakers blow. | 2. | Short circuit in motor or loose con- | 2. |

| Inspect all connections on motor for loose or shorted terminals or |

| ||||

|

|

|

| nections. |

|

| worn insulation. |

| ||

|

|

| 3. | Incorrect fuses or circuit breakers | 3. |

| Install correct fuses or circuit breakers. |

| ||

|

|

|

| in power line. |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

Motor overheats. |

| 1. | Motor overloaded. | 1. |

| Reduce load on motor. |

| |||

|

|

| 2. | Air circulation through the motor | 2. |

| Clean out motor to provide normal air circulation. |

| ||

|

|

|

| restricted. |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |

Motor stalls | (resulting in | 1. | Short circuit in motor or loose con- | 1. |

| Inspect connections on motor for loose or shorted terminals or worn |

| |||

blown fuses or tripped cir- |

| nections. |

|

| insulation. |

| ||||

cuit). |

|

| 2. | Low voltage. | 2 |

| Correct the low voltage conditions. |

| ||

|

|

| 3. | Incorrect fuses or circuit breakers | 3. |

| Install correct fuses or circuit breakers. |

| ||

|

|

|

| in power line. |

|

|

|

| ||

|

|

| 4. | Motor overloaded. | 4. |

| Reduce load on motor. |

| ||

|

|

|

|

|

|

|

|

| ||

Loud, repetitious noise com- | 1. | Pulley set screws or keys are miss- | 1. |

| Inspect keys and set screws. Replace or tighten if necessary. |

| ||||

ing from machine. |

|

| ing or loose. |

|

|

|

| |||

|

|

| 2. | Motor fan is hitting the cover. | 2. |

| Tighten fan or shim cover. |

| ||

|

|

| 3. | 3. |

| Replace |

| |||

|

|

|

|

|

|

|

|

|

| |

Conveyor belt not | tracking | 1. | Conveyor rollers moved out of | 1. |

|

| ||||

in center. |

|

|

| adjustment. |

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

Conveyor belt slipping. | 1. | Conveyor rollers have incorrect | 1. |

| Adjust conveyor rollers to place more tension on . |

| ||||

|

|

|

| tension. |

|

|

|

| ||

|

|

| 2. | Conveyor rollers contaminated with | 2. |

| Clean conveyor rollers. |

| ||

|

|

|

| dirt or dust. |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

Emergency | brake | stops | 1. | Air pressure incorrect. | 1. |

| Adjust air pressure to 75 PSI, |

| ||

slow. |

|

| 2. | Air leak in system. | 2. |

| Find and fix air leaks. |

| ||

|

|

| 3. | Brake rotor contaminated with oil. | 3. |

| Clean brake rotor with automotive brake parts cleaner. |

| ||

|

|

| 4. | Brake pads worn out. | 4. |

| Replace brake pads. |

| ||

|

|

|

|

|

|

|

|

| ||

Grinding noise when brak- | 1. | Brakes severely worn out. | 1. |

| Replace brake pads, have rotor turned (possibly replaced). |

| ||||

ing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Machine slows when oper- | 1. | Feed rate too high. | 1. |

| Feed workpiece slower. |

| ||||

ating. |

|

| 2. | Depth of cut too great. | 2. |

| Reduce depth of cut. |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G0527 18" Wide Belt Sander |