SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily Check:

•Vacuum all dust on and around the machine.

•Wipe down tables and all other unpainted cast iron with a metal protectant.

•Worn or damaged wires.

•Any other unsafe condition.

Monthly Check:

•

•Clean/vacuum dust buildup from inside cabi- net and off motor.

Lubrication

Since all bearings are sealed and permanently lubricated, simply leave them alone until they need to be replaced. DO NOT lubricate them.

Below is a list of components that require periodic lubrication. Be careful not to

Always disconnect power to the machine before lubricating! Failure to do this may result in serious personal injury.

Leadscrews: Lubricate with light machine oil as needed. See the location shown in Figure 46 and Part 23 and 48 on Page 41. Wipe off excess oil and sawdust with a cloth.

Figure 46. Leadscrew lubrication location.

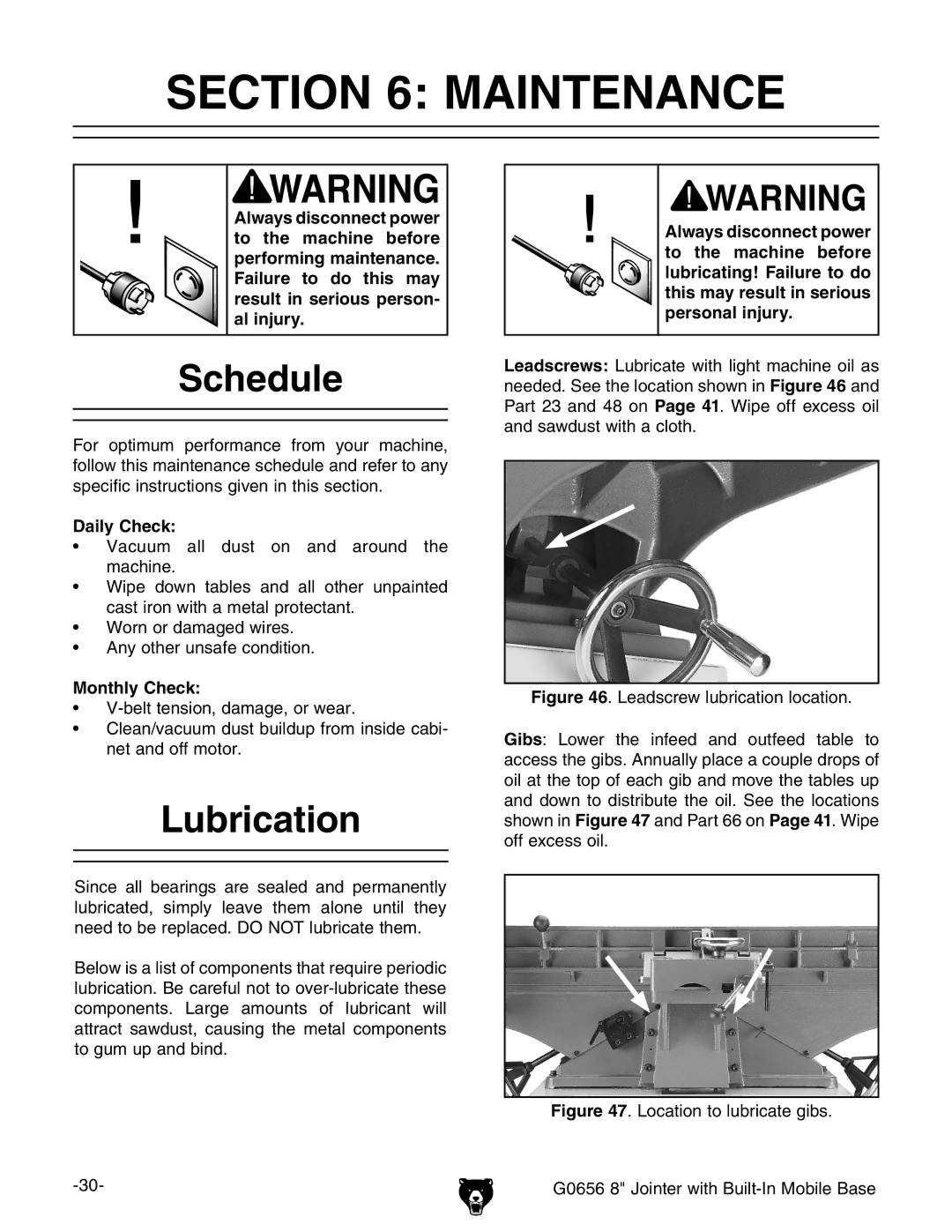

Gibs: Lower the infeed and outfeed table to access the gibs. Annually place a couple drops of oil at the top of each gib and move the tables up and down to distribute the oil. See the locations shown in Figure 47 and Part 66 on Page 41. Wipe off excess oil.

Figure 47. Location to lubricate gibs.

G0656 8" Jointer with |