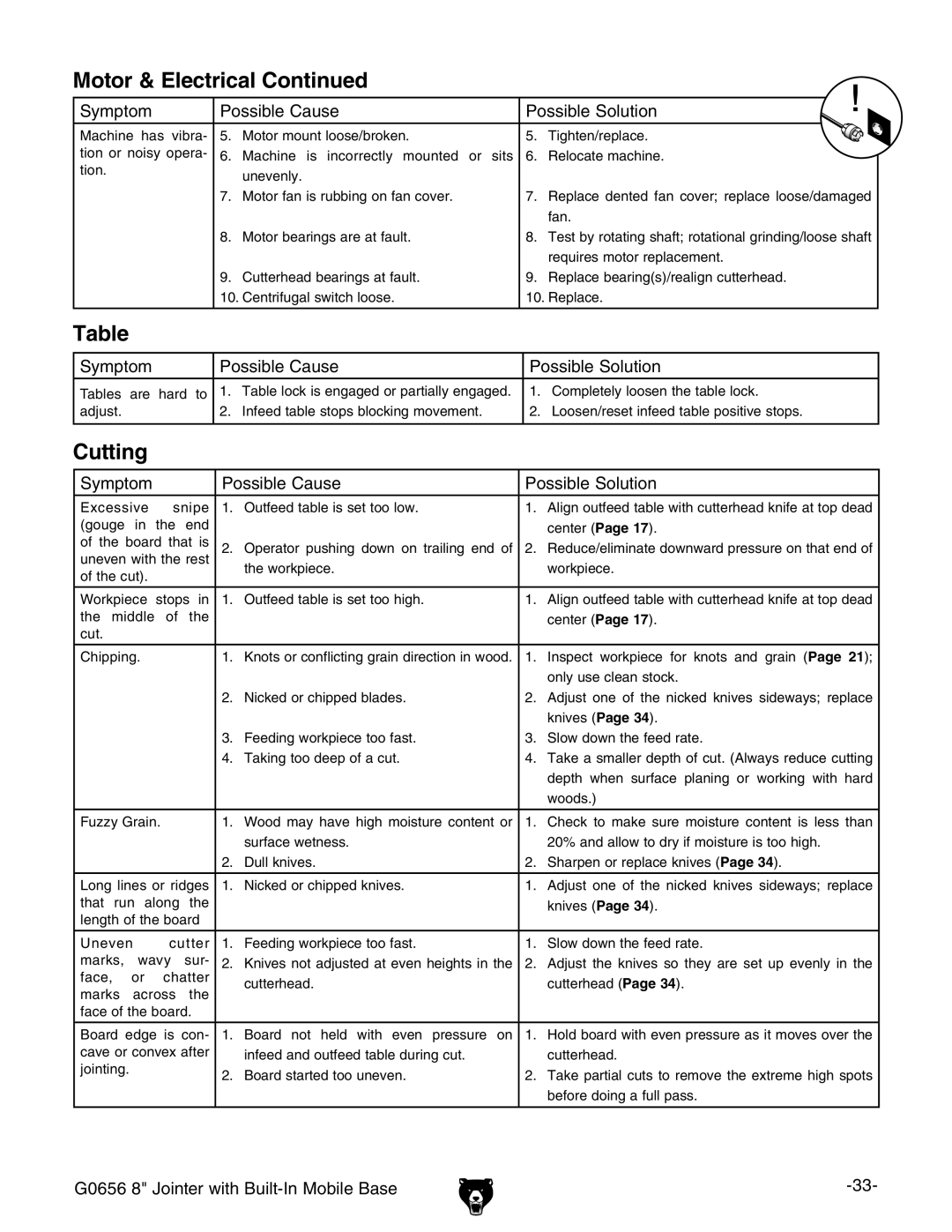

Motor & Electrical Continued

Symptom | Possible Cause | Possible Solution | ||

Machine has vibra- | 5. | Motor mount loose/broken. | 5. | Tighten/replace. |

tion or noisy opera- | 6. | Machine is incorrectly mounted or sits | 6. | Relocate machine. |

tion. |

| unevenly. |

|

|

|

|

|

| |

| 7. | Motor fan is rubbing on fan cover. | 7. | Replace dented fan cover; replace loose/damaged |

|

|

|

| fan. |

| 8. | Motor bearings are at fault. | 8. | Test by rotating shaft; rotational grinding/loose shaft |

|

|

|

| requires motor replacement. |

| 9. | Cutterhead bearings at fault. | 9. | Replace bearing(s)/realign cutterhead. |

| 10. Centrifugal switch loose. | 10. Replace. | ||

Table

Symptom | Possible Cause | Possible Solution | ||

|

|

|

|

|

Tables are hard to | 1. | Table lock is engaged or partially engaged. | 1. | Completely loosen the table lock. |

adjust. | 2. | Infeed table stops blocking movement. | 2. | Loosen/reset infeed table positive stops. |

|

|

|

|

|

Cutting

Symptom |

|

| Possible Cause | Possible Solution | |||

|

|

|

|

|

| ||

Excessive | snipe | 1. | Outfeed table is set too low. | 1. | Align outfeed table with cutterhead knife at top dead | ||

(gouge | in | the | end |

|

|

| center (Page 17). |

of the board that is | 2. | Operator pushing down on trailing end of | 2. | Reduce/eliminate downward pressure on that end of | |||

uneven with the rest |

| the workpiece. |

| workpiece. | |||

of the cut). |

|

|

|

| |||

|

|

|

|

|

| ||

|

|

|

|

|

| ||

Workpiece | stops in | 1. | Outfeed table is set too high. | 1. | Align outfeed table with cutterhead knife at top dead | ||

the middle | of | the |

|

|

| center (Page 17). | |

cut. |

|

|

|

|

|

|

|

Chipping. |

|

| 1. | Knots or conflicting grain direction in wood. | 1. | Inspect workpiece for knots and grain (Page 21); | |

|

|

|

|

|

|

| only use clean stock. |

|

|

|

| 2. | Nicked or chipped blades. | 2. | Adjust one of the nicked knives sideways; replace |

|

|

|

|

|

|

| knives (Page 34). |

|

|

|

| 3. | Feeding workpiece too fast. | 3. | Slow down the feed rate. |

|

|

|

| 4. | Taking too deep of a cut. | 4. | Take a smaller depth of cut. (Always reduce cutting |

|

|

|

|

|

|

| depth when surface planing or working with hard |

|

|

|

|

|

|

| woods.) |

|

|

|

|

|

| ||

Fuzzy Grain. |

| 1. | Wood may have high moisture content or | 1. | Check to make sure moisture content is less than | ||

|

|

|

|

| surface wetness. |

| 20% and allow to dry if moisture is too high. |

|

|

|

| 2. | Dull knives. | 2. | Sharpen or replace knives (Page 34). |

|

|

|

|

| |||

Long lines or ridges | 1. | Nicked or chipped knives. | 1. | Adjust one of the nicked knives sideways; replace | |||

that run along | the |

|

|

| knives (Page 34). | ||

length of the board |

|

|

|

| |||

Uneven | cutter | 1. | Feeding workpiece too fast. | 1. | Slow down the feed rate. | ||

marks, | wavy | sur- | 2. | Knives not adjusted at even heights in the | 2. | Adjust the knives so they are set up evenly in the | |

face, | or | chatter |

| cutterhead. |

| cutterhead (Page 34). | |

marks | across | the |

|

| |||

|

|

|

| ||||

face of the board. |

|

|

|

| |||

|

|

|

|

| |||

Board edge is con- | 1. | Board not held with even pressure on | 1. | Hold board with even pressure as it moves over the | |||

cave or convex after |

| infeed and outfeed table during cut. |

| cutterhead. | |||

jointing. |

|

|

| 2. | Board started too uneven. | 2. | Take partial cuts to remove the extreme high spots |

|

|

|

| ||||

|

|

|

|

|

|

| before doing a full pass. |

|

|

|

|

|

|

|

|

G0656 8" Jointer with |