Adjusting Spindle

Speeds

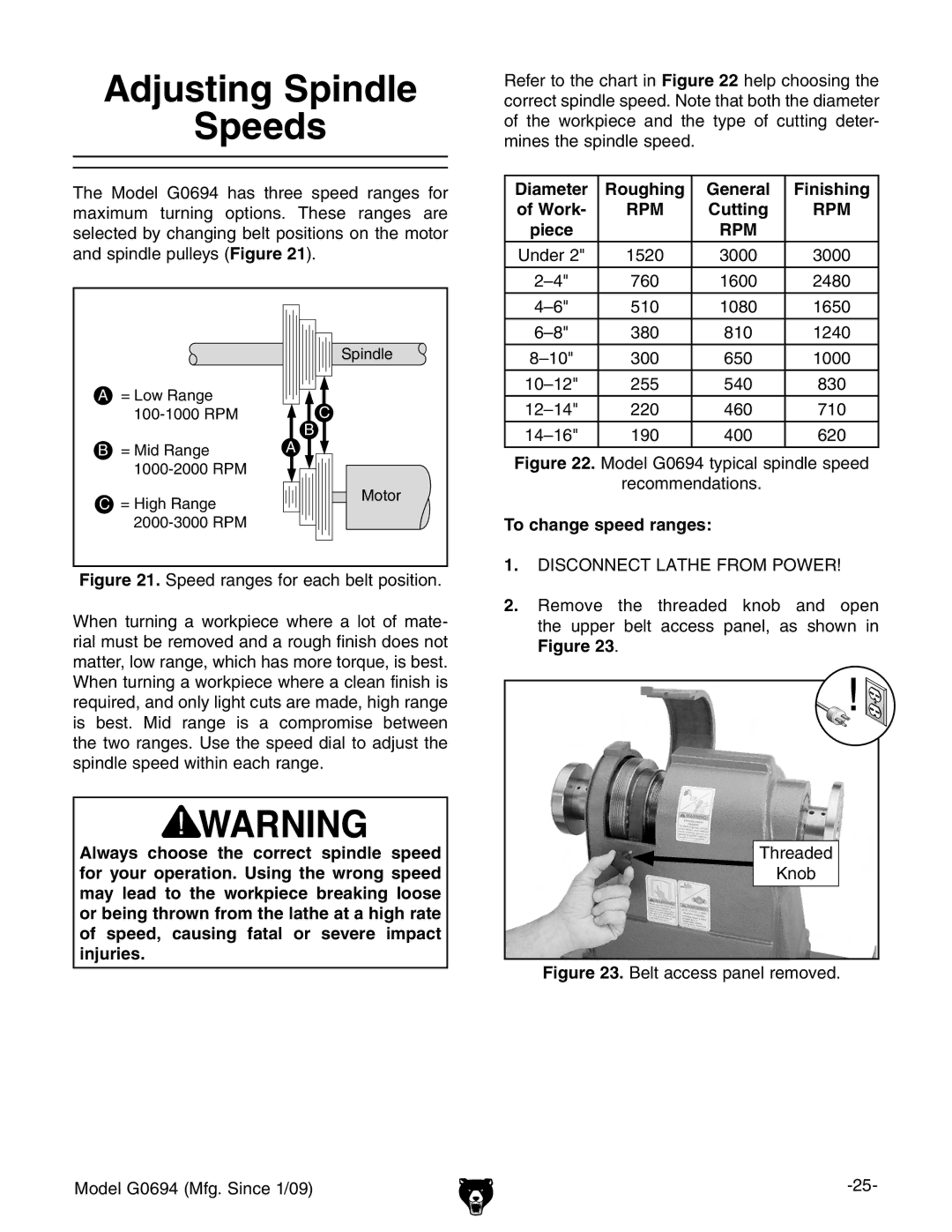

The Model G0694 has three speed ranges for maximum turning options. These ranges are selected by changing belt positions on the motor and spindle pulleys (Figure 21).

Refer to the chart in Figure 22 help choosing the correct spindle speed. Note that both the diameter of the workpiece and the type of cutting deter- mines the spindle speed.

Diameter | Roughing | General | Finishing |

of Work- | RPM | Cutting | RPM |

piece |

| RPM |

|

Under 2" | 1520 | 3000 | 3000 |

760 | 1600 | 2480 | |

510 | 1080 | 1650 | |

|

|

|

|

380 | 810 | 1240 |

A= Low Range

B= Mid Range

C= High Range

Spindle

C

B

A |

Motor

300 | 650 | 1000 | |

|

|

|

|

255 | 540 | 830 | |

|

|

|

|

220 | 460 | 710 | |

|

|

|

|

190 | 400 | 620 |

Figure 22. Model G0694 typical spindle speed

recommendations.

To change speed ranges:

Figure 21. Speed ranges for each belt position.

When turning a workpiece where a lot of mate- rial must be removed and a rough finish does not matter, low range, which has more torque, is best. When turning a workpiece where a clean finish is required, and only light cuts are made, high range is best. Mid range is a compromise between the two ranges. Use the speed dial to adjust the spindle speed within each range.

Always choose the correct spindle speed for your operation. Using the wrong speed may lead to the workpiece breaking loose or being thrown from the lathe at a high rate of speed, causing fatal or severe impact injuries.

Model G0694 (Mfg. Since 1/09)

1.DISCONNECT LATHE FROM POWER!

2.Remove the threaded knob and open the upper belt access panel, as shown in

Figure 23.

Threaded

Knob